Graphene-loaded rhombohedron ferric oxide composite material and hydrothermal synthesis method thereof

A composite material, hydrothermal synthesis technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high rate and long-cycle cycle performance, single structure of iron oxide particles, complex preparation process, etc., to achieve the preparation cycle Short, simple preparation process, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

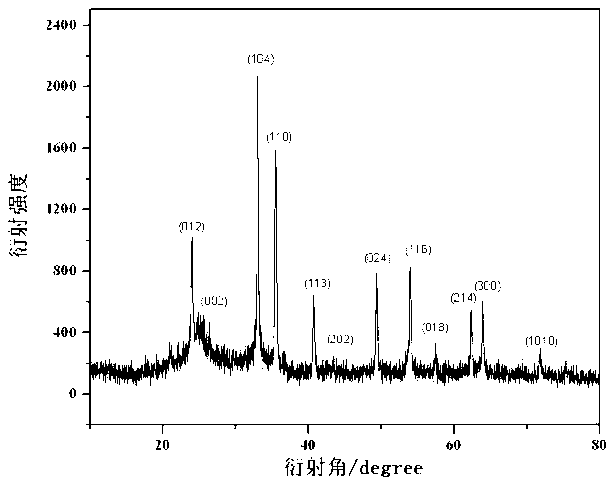

[0031] Embodiment one : Preparation of graphene-supported rhombohedral iron oxide composites using ferric sulfate as iron source.

[0032] Potassium persulfate (K 2 S 2 o 8 ) 2.5 g, phosphorus pentoxide (P 2 o 5 ) 2.5 g, dissolved in 12 mL of concentrated sulfuric acid, heated to 80°C; then 3 g of natural graphite was added to the above solution, kept at 80°C for 4.5 hours; cooled to room temperature, diluted with 500 mL of deionized water, and left standing overnight ; filter, float residual acid with 0.2 mm filter; dry in a vacuum oven at 60°C; add the obtained preoxide to 120 mL of ice-bathed concentrated sulfuric acid, slowly add 15 g of KMnO under stirring 4 , Keep the temperature below 20°C during the addition process. Then the temperature was controlled at 35°C and stirred for 2 h. Add 250 mL of deionized water to dilute, and keep the temperature below 50°C in an ice bath during the dilution process. Stir for another 2 h, add 0.7 L of deionized water, and immed...

Embodiment 2

[0036] Embodiment two : Preparation of graphene-supported rhombohedral iron oxide composites using ferric nitrate as iron source.

[0037] Add 0.808g of ferric nitrate into 100 mL of deionized water, add 100 mg of graphene into it, stir for 15 min, sonicate for 0.5 h, then add 0.50 g of NaAc and stir for 30 min, then transfer to the reaction kettle and heat at 160°C for 24 hours, centrifuge, ethanol washing and water washing 3 times each, and drying at 80°C to obtain the product.

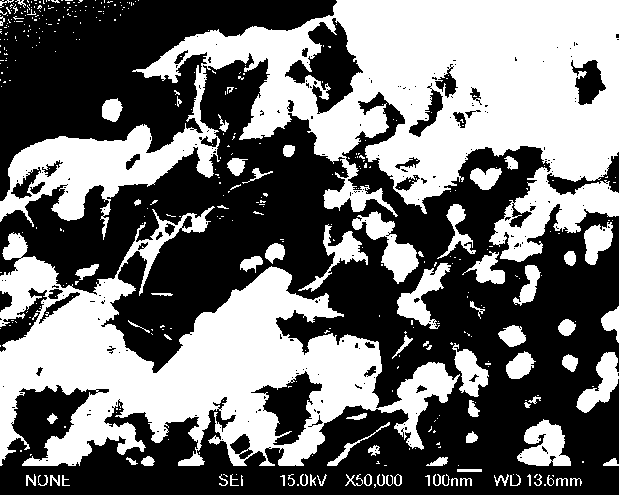

[0038] The scanning electron microscope photo of the dried product is shown in figure 2 , it can be seen from the figure that the rhombohedral iron oxide has a diameter of 50-100 nm, and each surface is a parallelogram deformation. The reversible capacity is 1037.2 mAh / g at a current density of 100 mA / g in the voltage window of 5mV-3.0 V, and it can still maintain 677.2 mAh / g after 50 charge-discharge cycles.

Embodiment 3

[0039] Embodiment Three : Preparation of graphene-loaded rhombohedral iron oxide composites using iron acetate as iron source.

[0040] Take 0.246 g of ferric acetate and add it to 50 mL of deionized water, add 50 mg of graphene to it, stir for 15 min, sonicate for 0.5 h, then add 0.5 g of NaAc and stir for 30 min, then transfer to the reaction kettle and heat at 180°C for 24 hours, centrifuge, ethanol washing and water washing 3 times each, and drying at 80°C to obtain the product.

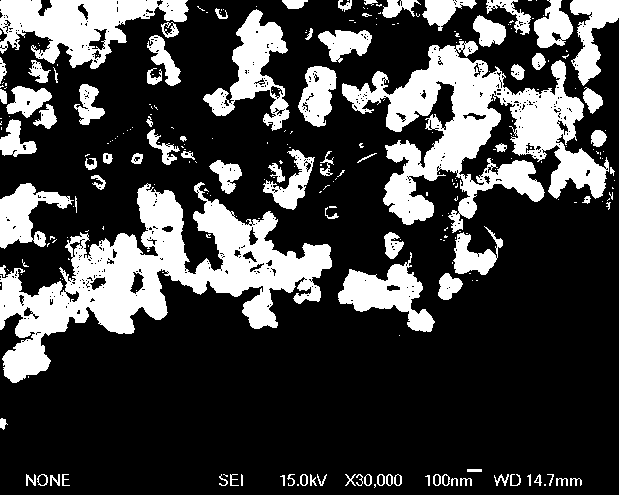

[0041] The scanning electron microscope photograph of the product is shown in image 3 , it can be seen that rhombohedral iron oxide particles with a diameter of 80-150 nm are evenly loaded on the surface of graphene, and no obvious agglomeration and stacking phenomenon is seen. And some particles are covered by a layer of transparent tulle graphene, indicating that the rhombohedral iron oxide particles are distributed on both sides of the graphene. Electrochemical tests show that the prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com