Preparation method for graphitized porous carbon for supercapacitor

A supercapacitor and graphitization technology, applied in the preparation/purification of carbon, etc., can solve the problems of capacitive surface area limitation, poor conductivity, and charge transfer constraints, and achieve strong energy storage and release capabilities, easy operation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

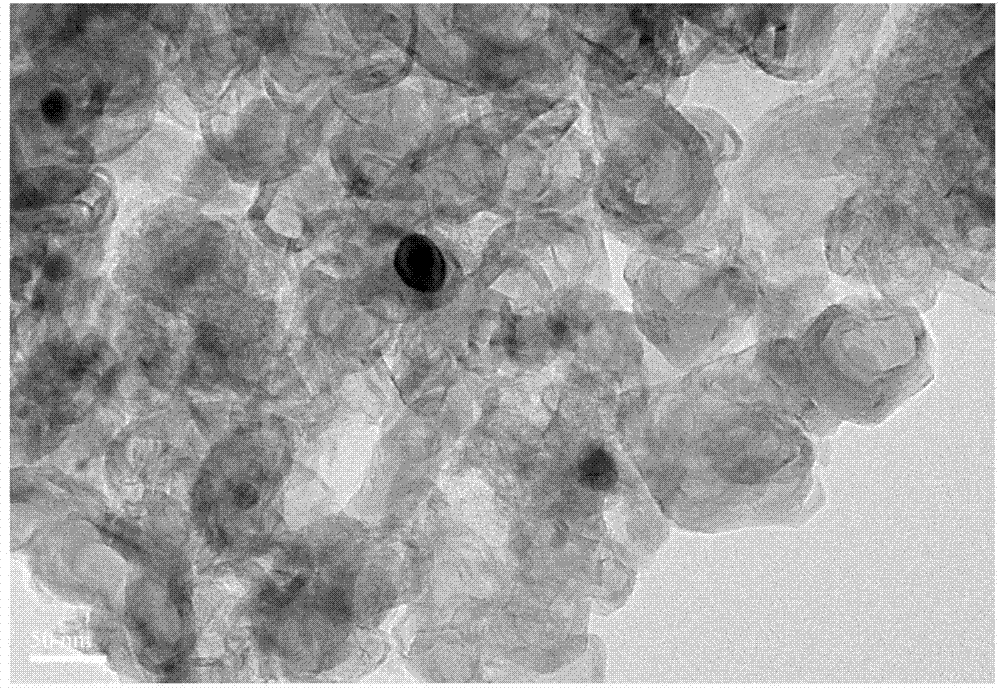

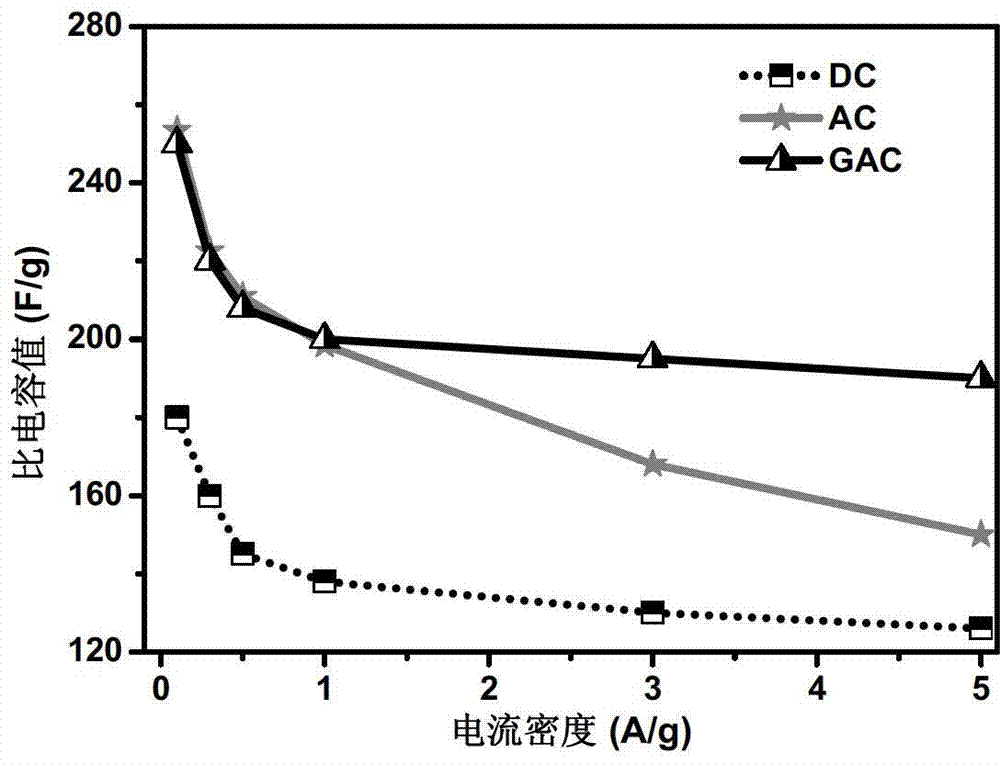

Image

Examples

Embodiment 1

[0030] This embodiment relates to a preparation method of graphitized porous carbon for supercapacitors, comprising the following steps:

[0031] Step 1: Calcinate 30g of macroalgae at 400°C for 1 hour under vacuum, add 1L of hydrochloric acid (3mol / L), stir for 2 hours, filter, and dry to obtain carbonized seaweed powder;

[0032] Step 2: Add 3g of carbonized seaweed powder into 20ml of KOH (1mol / L), heat at 100°C until evaporated to dryness, and calcinate at 450-500°C to obtain an activated product;

[0033] Step 3: Add the activated product obtained in the above step 2 into 1L of hydrochloric acid (1mol / L), stir for 2 hours, filter, and dry at 100°C to obtain activated seaweed carbon.

[0034] Step 4, take 1g of the activated seaweed carbon obtained in the above step 3 and add 0.2mol / L Ni(NO 3 ) 2 In acetone solution, ultrasonic treatment was performed for 1 hour to obtain product A;

[0035] Step 5: filter the product A, dry at 80°C, calcinate at 900°C at high temperatu...

Embodiment 2

[0038] This embodiment relates to a preparation method of graphitized porous carbon for supercapacitors, comprising the following steps:

[0039] Step 1: Calcinate 30g of Undaria pinnatifida under vacuum at 600°C for 2 hours, add 1L of hydrochloric acid (5mol / L), stir for 2 hours, filter, and dry to obtain carbonized seaweed powder;

[0040] Step 2: Add 3g of carbonized seaweed powder into 20ml of KOH (4mol / L), heat at 100°C until evaporated to dryness, and calcinate at 450-800°C to obtain an activated product;

[0041] Step 3: Add the activated product obtained in the above step 2 into 1L of hydrochloric acid (1mol / L), stir for 2 hours, filter, and dry at 100°C to obtain activated seaweed carbon.

[0042] Step 4, take 1g of the activated seaweed carbon obtained in the above step 3 and add 0.5mol / L Co(NO 3 ) 2 In ethanol solution, sonicated for 1 hour to obtain product A;

[0043] Step 5: Filter the product A, dry at 80°C, calcinate at 700°C at high temperature, wash with 1...

Embodiment 3

[0046] This embodiment relates to a preparation method of graphitized porous carbon for supercapacitors, comprising the following steps:

[0047]Step 1: Calcinate 30g of seaweed at 900°C for 3 hours under vacuum, add 1L of hydrochloric acid (2mol / L), stir for 2 hours, filter, and dry to obtain carbonized seaweed powder;

[0048] Step 2: Add 3g of carbonized seaweed powder into 20ml of NaOH (7mol / L), heat at 100°C until evaporated to dryness, and calcinate at 450-900°C to obtain an activated product;

[0049] Step 3: Add the activated product obtained in the above step 2 into 1L of hydrochloric acid (1mol / L), stir for 2 hours, filter, and dry at 100°C to obtain activated seaweed carbon.

[0050] Step 4, take 1g of the activated seaweed carbon obtained in the above step 3 and add 0.5mol / L FeCl 3 In aqueous solution, sonicated for 1 hour to obtain product A;

[0051] Step 5: filter the product A, dry at 80°C, calcinate at 1000°C, wash with 1 L of hydrochloric acid (1mol / L), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com