Ginsenoside C-K monohydrate crystal and preparation method thereof

A technology of ginsenoside and monohydrate, which is applied in the field of ginsenoside C-K monohydrate crystal and preparation to achieve the effects of improving crystallization yield, avoiding explosive nucleation and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method that this example produces ginsenoside C-K monohydrate crystal specifically comprises the following steps:

[0028] 1) Add 18.0126g of crude ginsenoside C-K into 260ml of acetonitrile and water mixed solvent with a mass ratio of 1.5:1, dissolve it completely at 60°C, then raise the temperature to 63°C to ensure that ginsenoside C-K is completely dissolved, and add Condensation reflux device to avoid solvent volatilization;

[0029] 2) Cool down the saturated solution obtained above at a rate of 0.15°C / min, add 1% seed crystals when the temperature drops to 43°C, and maintain the temperature of seed crystals for 30 minutes to consume the supersaturation in the solution;

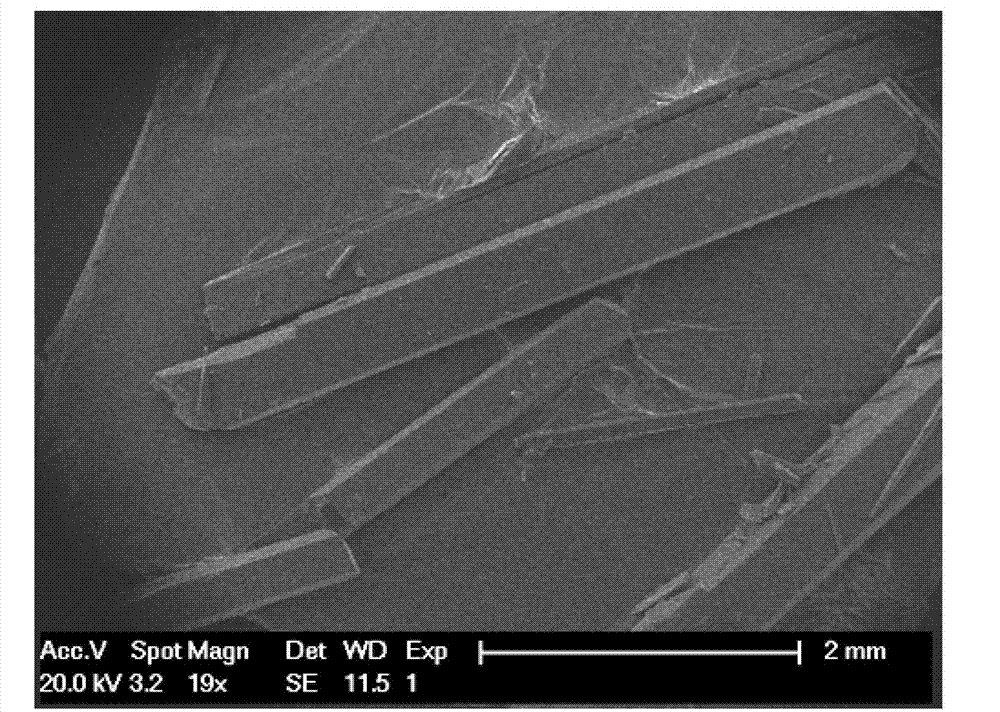

[0030] 3) After constant temperature stirring, continue to drop the temperature to 4°C at a cooling rate of 0.3°C / min, grow crystals at 4°C for 1 hour, filter and wash, and dry at 60°C for 1 hour under a vacuum of 0.08Mp-0.1Mp to obtain the product Ginsenoside C-K monohydrate, the yield is m...

Embodiment 2

[0034] The method that this example produces ginsenoside C-K monohydrate crystal specifically comprises the following steps:

[0035] 1) Add 8.1265g of crude ginsenoside C-K into 300ml of acetonitrile and water mixed solvent with a mass ratio of 1:1, dissolve it completely at 60°C, and then raise the temperature to 63°C to ensure that ginsenoside C-K is completely dissolved, and add Condensation reflux device to avoid solvent volatilization;

[0036] 2) Cool down the saturated solution obtained above at a rate of 0.1°C / min, add 0.5% seed crystals when the temperature drops to 45°C, and maintain the seeding temperature for 60 minutes to consume the supersaturation in the solution;

[0037] 3) After constant temperature stirring, continue to drop the temperature to 4°C at a cooling rate of 0.2°C / min, grow crystals at 4°C for 1 hour, filter and wash, and dry at 50°C for 1 hour under a vacuum of 0.08Mp-0.1Mp to obtain the product Ginsenoside C-K monohydrate, the yield is more tha...

Embodiment 3

[0041] The method that this example produces ginsenoside C-K monohydrate crystal specifically comprises the following steps:

[0042] 1) Add 9.6338g of crude ginsenoside C-K into 310ml of acetonitrile and water mixed solvent with a mass ratio of 2:1, dissolve it completely at 60°C, then raise the temperature to 63°C to ensure that ginsenoside C-K is completely dissolved, and add Condensation reflux device to avoid solvent volatilization;

[0043] 2) Cool down the saturated solution obtained above at 0.2°C / min, add 3% seed crystals when the temperature drops to 40°C, and maintain the seeding temperature for 60 minutes to consume the supersaturation in the solution;

[0044] 3) After constant temperature stirring, continue to drop the temperature to 4°C at a cooling rate of 0.4°C / min, grow crystals at 4°C for 1 hour, filter and wash, and dry at 55°C for 1 hour under a vacuum of 0.08Mp-0.1Mp to obtain the product Ginsenoside C-K monohydrate, the yield is more than 90%.

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com