Chlorosulfonated polyethylene (CSM) rubber/butyl rubber gasket and preparation method thereof

A technology of chlorosulfonated polyethylene and butyl rubber, which is applied in chemical instruments and methods, dyed low-molecular-weight organic compound treatment, dyed high-molecular-weight organic compound treatment, etc. and other problems, to achieve the effect of good corrosion resistance, good wear resistance and excellent effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

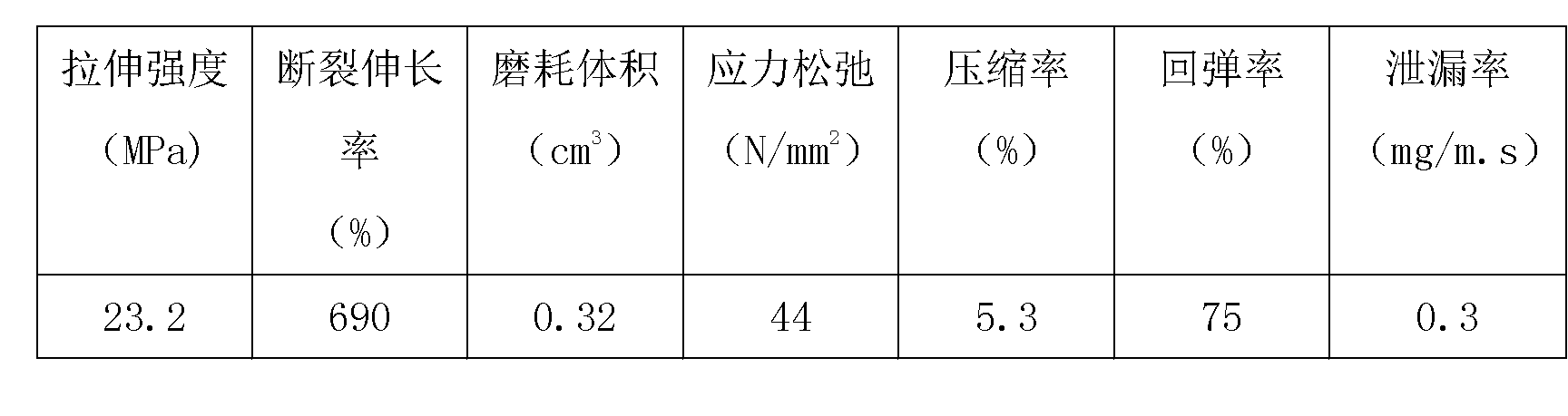

Examples

Embodiment

[0015] A chlorosulfonated polyethylene rubber / butyl rubber sealing gasket, the weight parts of which are composed of raw materials are: 140 parts of chlorosulfonated polyethylene rubber CSM2305, 10 parts of butyl rubber CBK139, 15 parts of butyl rubber BBK232, glycerol triacetate 5 parts of ester, 4 parts of epoxidized soybean oil, 3 parts of glycerol triglyceride, 5 parts of magnesium oxide, 2 parts of isooctyl dithioglycolate, 2 parts of di-n-octyl tin, 8 parts of zinc oxide, 6 parts of attapulgite, nano 22 parts of dolomite powder, 25 parts of bauxite powder, 12 parts of carbon black N339, 1.5 parts of titanate coupling agent TMC-TTS, 1.8 parts of antioxidant 1010, 2 parts of phenyltriethoxysilane, silane coupling 1.5 parts of anti-aging agent KH550, 1 part of anti-aging agent ODA, 2 parts of anti-aging agent RD, 2 parts of 2-mercaptobenzimidazole, 1.5 parts of accelerator CZ, 0.8 parts of accelerator CBS, 0.15 parts of accelerator Na-22, modified 2 pieces of tree ash.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com