Flame-retardant and oil-resistant marine rubber material and molding preparation method thereof

A rubber material and marine technology, applied in the field of rubber products, can solve the problems of lead-containing compounds being highly toxic, poor water resistance and oil resistance, etc., and achieve good UV resistance and ozone resistance, strong aging resistance, and excellent performance The effect of oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

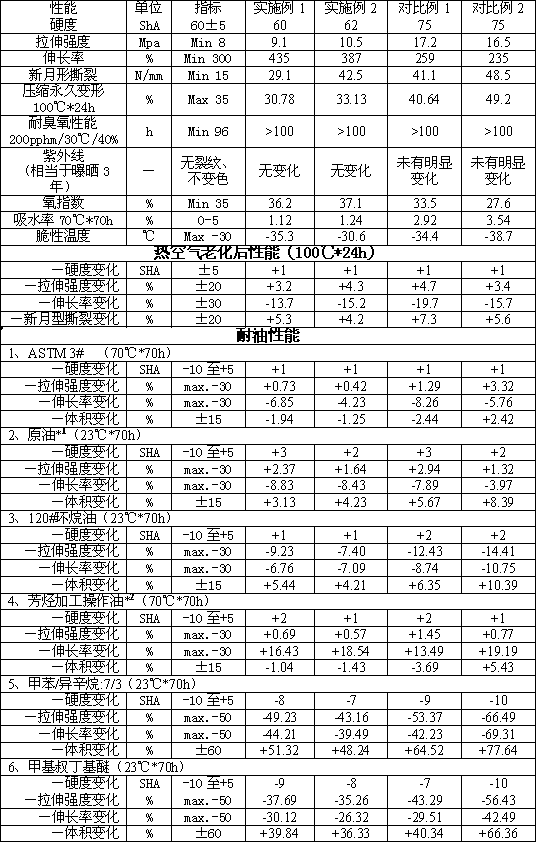

Examples

Embodiment 1

[0039] The components and parts by mass are: 3695 granular CSM produced by Lianyungang Jintaida Company, 60 parts; nitrile rubber N230S produced by Japan JSR Company, 40 parts; carbon black N550, 25 parts; chlorinated paraffin 50 parts , 30 parts; decabromodiphenyl ether, 20 parts; antimony trioxide, 20 parts; barium sulfate, 10 parts; zinc oxide, 1.5 parts; stearic acid, 1 part; antioxidant RD, 1.5 parts; reactive antiaging anti-aging agent NBC, 0.8 parts; microcrystalline wax, 2 parts; ultraviolet absorber, 2 parts; processing aids RL-20 and RF-70 produced by Guangzhou Jinchangsheng Technology Co., Ltd. Agent CZ, 0.4 parts; Accelerator TMTD, 0.2 parts; Sulfur, 0.3 parts; HVA-2, 2 parts.

[0040] The preparation technology of embodiment 1 is: on 16 cun open type rubber mixing machines, granular chlorosulfonated polyethylene rubber and acrylonitrile-butadiene rubber are respectively blended to uniformity after 10 times of wrapping with minimum roll spacing; Add materials afte...

Embodiment 2

[0043] Each component and mass parts are: CSM40 produced by domestic Jilin Chemical Company, 80 parts; Nitrile rubber N220S produced by Japan JSR Company, 20 parts; Carbon black SP5000, 30 parts; Chlorinated paraffin 50 (liquid, plasticized agent), 30 parts; chlorinated paraffin wax 70 (solid, flame retardant), 30 parts; clay, 10 parts; antimony trioxide, 15 parts; zinc oxide, 1 part; stearic acid, 1 part; antioxidant RD , 1 part; reactive anti-aging agent MC, 1 part; anti-aging agent AW, 1 part; microcrystalline wax, 1 part; ultraviolet absorber, 2 parts; processing aid RL-20 and RF-70 each 1.5 parts; Accelerator CZ, 0.5 parts; Accelerator DPTT, 0.4 parts; Sulfur, 0.3 parts; HVA-2, 2.5 parts.

[0044] The preparation process of Example 2 is as follows: first pass CSM and NBR 10 times with the minimum roll distance on a 16-inch open rubber mixing machine; then raw rubber, carbon black, plasticizer, protective agent, etc. Add it to the closed rubber mixer and mix evenly, disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com