Preparation for producing instant xanthan gum and use method of preparation

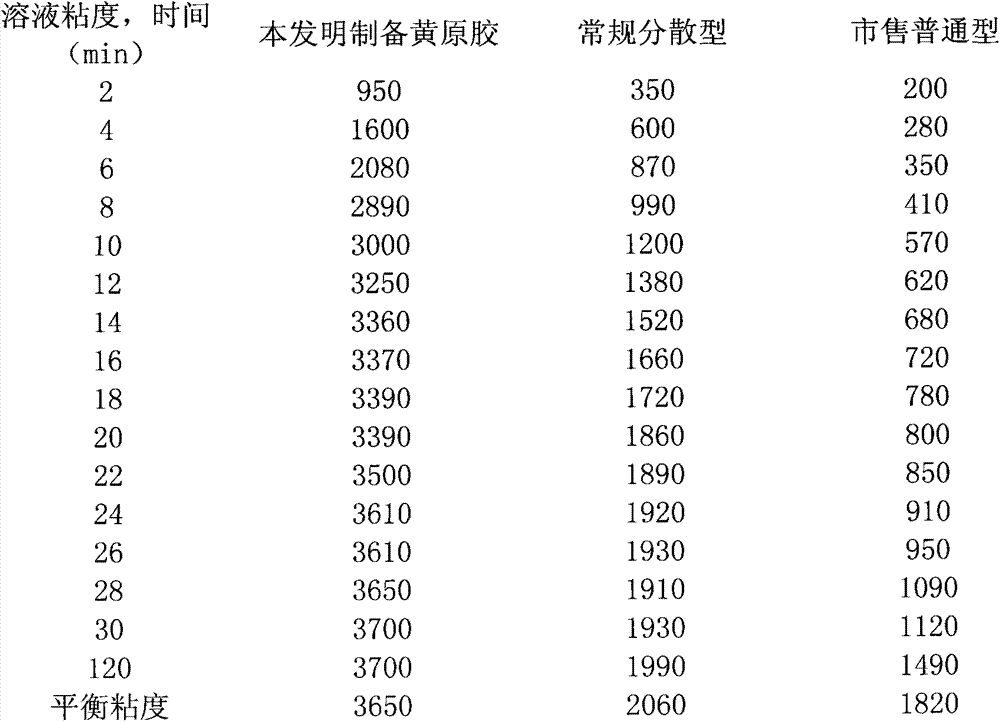

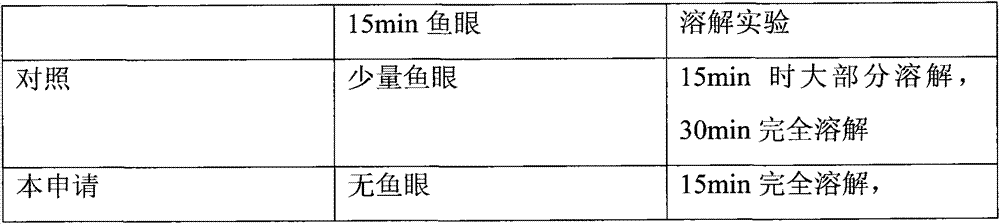

A xanthan gum, instant technology, applied in the field of microorganisms, can solve the problems of unstable aqueous solution viscosity, reduced use efficiency, product quality decline, etc., to achieve the effect of improving production process, product quality stability, and product viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] 1. Preparation of Xanthan Gum

[0031] (1) Preparation of mixed fermentation broth: Xanthomonas mixed bacteria solution: Xanthomonas campestris ATCC19046 (see IMPROVED XANTHAN GUM, WO201011249, 2010) and Xanthomonas Xanthomonas.SP CGMCCNO: 3624 ( CN101906390A) and Xanthomonas axonopodis ATCC17915 (referring to Bacteriocins and temperate phage of Xanthomonas campestris pv.Glycines, 1987) and Oriental Issar yeast (Issatchenkia orientalis Z1) CCTCC M2010167 (referring to CN102102084), four kinds of bacterial liquid volume ratios are : 3:2:1 inoculation, the concentration of bacteria in the bacterial liquid is about 1×10 8CFU / mL, according to the inoculation amount of 5% (volume ratio), insert in the seed jar and cultivate, at temperature, be 30 ℃, under the condition of pH value 7.2, cultivate 15 hours to obtain seed culture liquid, according to 2% (seed culture liquid : The inoculation ratio of the fermented liquid volume ratio 2%) is transferred to the fermenter for cul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com