Novel multilayer film capable of improving extreme ultraviolet spectrum purity and thermal stability

A technology of thermal stability and extreme ultraviolet light, which is applied in the field of extreme ultraviolet lithography, can solve the problem of high reflectivity in the out-of-band band, and achieve the effect of suppressing reflectivity and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

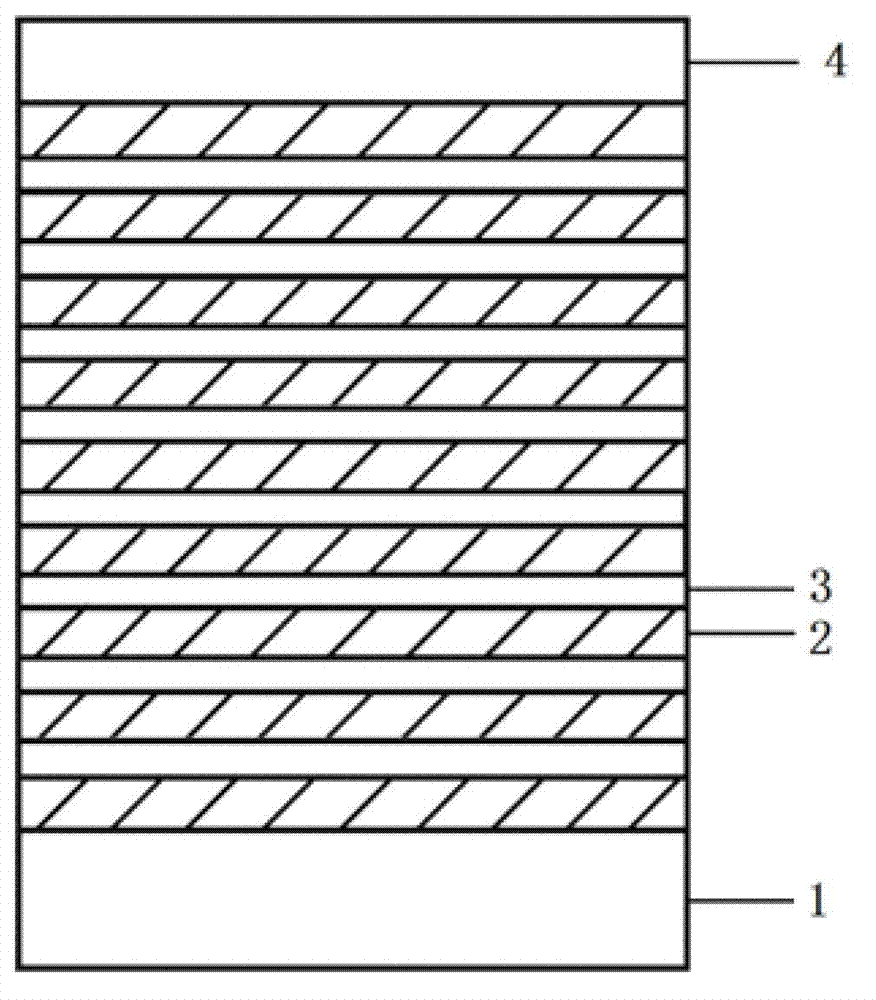

[0018] Such as figure 1 As shown, a novel multilayer film that improves extreme ultraviolet spectral purity and thermal stability, the novel multilayer film is a periodic multilayer film in which Si layers 2 and Mo layers 3 are alternately plated on a substrate 1, and includes A thermal stability layer 4, the thermal stability layer 4 is fabricated on a periodic multilayer film in which Si layers 2 and Mo layers 3 alternate.

[0019] The preferred layer period of the periodic multilayer film in which Si layer 2 and Mo layer 3 alternate is 40-60, and one layer corresponds to a Si layer and the Mo layer adjacent to the Si layer, wherein in the periodic multilayer film, Si The thicknesses of the Mo layer and the Mo layer were not changed. Due to the limited depth of action of the radiation in this spectral region, a further increase in the numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com