Novel aluminum nanometer particle surface plasmon enhanced solar battery

A surface plasmon and solar cell technology, applied in the field of solar cells, can solve problems such as density increase, matching, and carrier surface recombination, so as to improve efficiency, improve light absorption, and overcome carrier surface recombination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

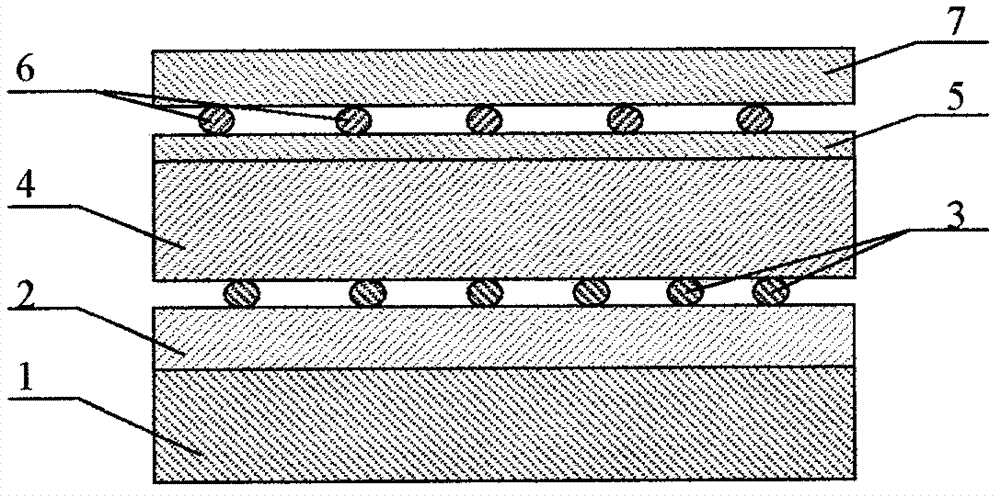

[0016] Such as figure 1 , on the stainless steel substrate (1), use magnetron sputtering equipment to deposit ITO or AZO transparent conductive film (2) in the vacuum chamber, the background vacuum degree reaches 6*10 -4 Pa, the film thickness is between 50-100nm; deposit aluminum film in the same sputtering vacuum chamber, the deposition pressure is 0.8-3Pa, the substrate temperature is 120°C-200°C, and the film thickness is between 15nm-60nm; The film is annealed in situ or under the protection of nitrogen, the annealing temperature is maintained at 300°C-400°C, and the annealing time is 1.5-3 hours to form an aluminum nanoparticle array (3), the size of which is between 20-60nm, which can be passed Extend the annealing time to reduce its density without using photolithography; use chemical vapor deposition on the aluminum nanoparticle array to prepare a conventional NIP junction (4), and its material can be a silicon film or a silicon-germanium alloy film; use a magnetic C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com