Method and device for treating waste gas and waste liquid in ethylene glycol production

A technology of ethylene glycol and waste gas, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of waste gas and waste liquid pollution of the environment, and achieve the effect of solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

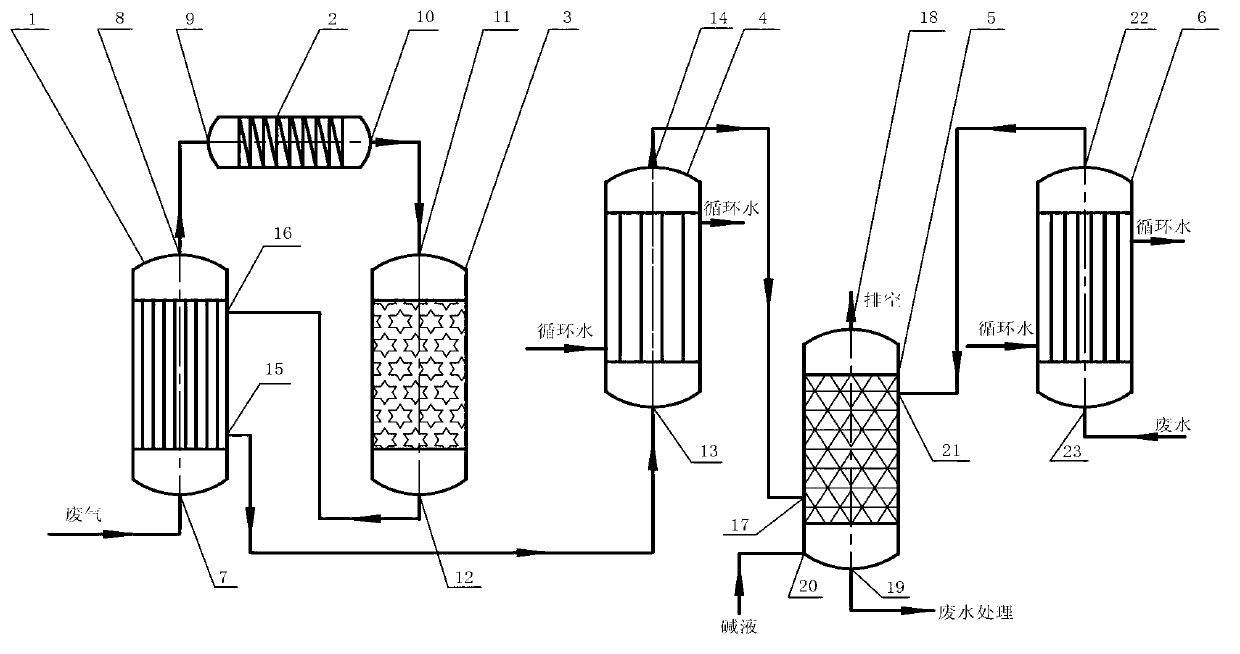

[0046] A kind of method of the present invention is used to process waste gas and waste liquid that produces in ethylene glycol production, and it comprises the following steps:

[0047](a) The exhaust gas produced in the production of ethylene glycol is heated to 200°C through the heat exchanger 1, and the heat exchanger 1 uses the reacted gas discharged from the reactor 3 in step b to heat the gas entering the heat exchanger The exhaust gas in 1; after being heated by heat exchanger 1, the exhaust gas is heated to 230°C-240°C by heater 2, preferably 235°C;

[0048] (b) Send the heated exhaust gas into the reactor (3), which is equipped with a platinum / alumina catalyst. Under the action of the catalyst, the methyl nitrite in the exhaust gas reacts to form methanol, and the exhaust gas Nitric oxide, hydrogen and carbon monoxide interact to form nitrogen, water, carbon dioxide and ammonia, and the reaction formula is as follows:

[0049] CH 3 ONO+H 2 =CH 3 OH+NO

[0050] N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com