Production method for alkyl ketene dimer

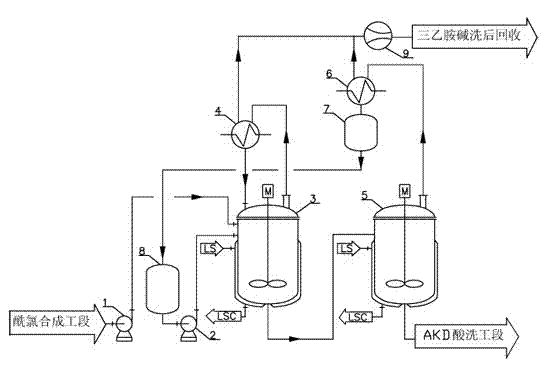

A technology of alkyl ketene dimer and production method, which is applied in the direction of organic chemistry, can solve the problems of high viscosity of reaction material system, large amount of waste brine production, high energy consumption in the production process, etc., to overcome the small cooling area and the reaction High mass transfer efficiency and stable reaction temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

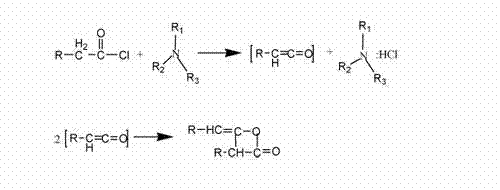

Method used

Image

Examples

Embodiment 1

[0024] The size of the reaction kettle 3 used is φ425×800 mm, and the size of the amine steamer 5 is φ425×600 mm. First, use the amine delivery pump 2 to pump 20 kg of triethylamine to keep the pressure in the reaction kettle 3 at 15-20 kPa. Rotate at 450 rpm, heat to 40-45°C to evaporate triethylamine, and circulate cooling; simultaneously turn on acid chloride delivery pump 1 and amine delivery pump 2 to pump stearoyl chloride and triethylamine, and adjust the flow rate of stearoyl chloride to 1.95 kg / h, the flow rate of triethylamine is 1.31 kg / h, close the reactor heating steam, when the liquid level reaches 70%, start to continuously pump into the amine still 5 with a gear pump, and the stirring of the amine still 5 is controlled at 150 rpm / min, the pressure is controlled at 10-20kPa, heated with steam, the temperature is controlled at 40-45°C, and when the liquid level of amine steamer 5 reaches 60%, it starts to discharge continuously. After 2.0 hours of continuous o...

Embodiment 2

[0026] The equipment is the same as in Example 1, except that the reaction temperature is controlled at 50-55°C, the flow rate and control liquid level remain unchanged, and the residence time remains unchanged. After 2.0 hours of continuous operation, sampling from the outlet of the amine still Routine pickling and separation after standing still, the organic phase was distilled and sampled by IR spectrum measurement, and the lactone content was determined to be 92.6% (by weight).

Embodiment 3

[0028] The equipment is the same as in Example 1, the reaction temperature is controlled at 50-55°C, but the convective flow rate is increased to twice that of Example 1, and after 2.0 hours of continuous operation, samples are taken from the outlet of the amine distillation kettle and left to stand after conventional pickling. After separation, the organic phase was distilled and then sampled and measured by IR spectrum, and the content of lactone was determined to be 92.1% (by weight).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com