Preparation method for octreotide

A technology of octreotide and peptide resin, which is applied in the field of compound synthesis, can solve the problems of low purity, low octreotide yield, and high loss rate of fragment 6, etc., and achieve the goals of reducing operation steps, increasing product yield and purity, and increasing reaction yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

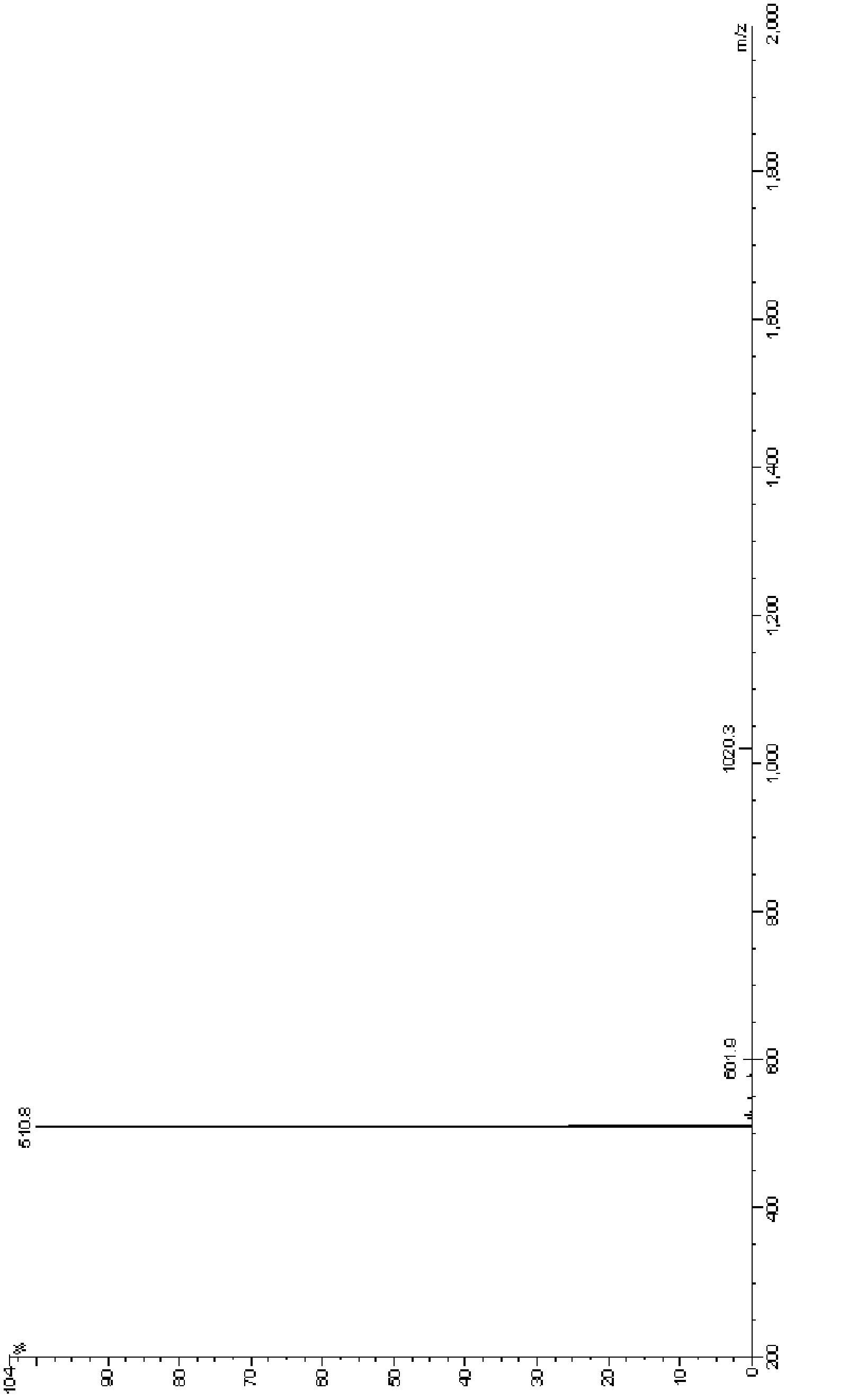

Image

Examples

preparation example Construction

[0034] The invention discloses a preparation method of octreotide, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

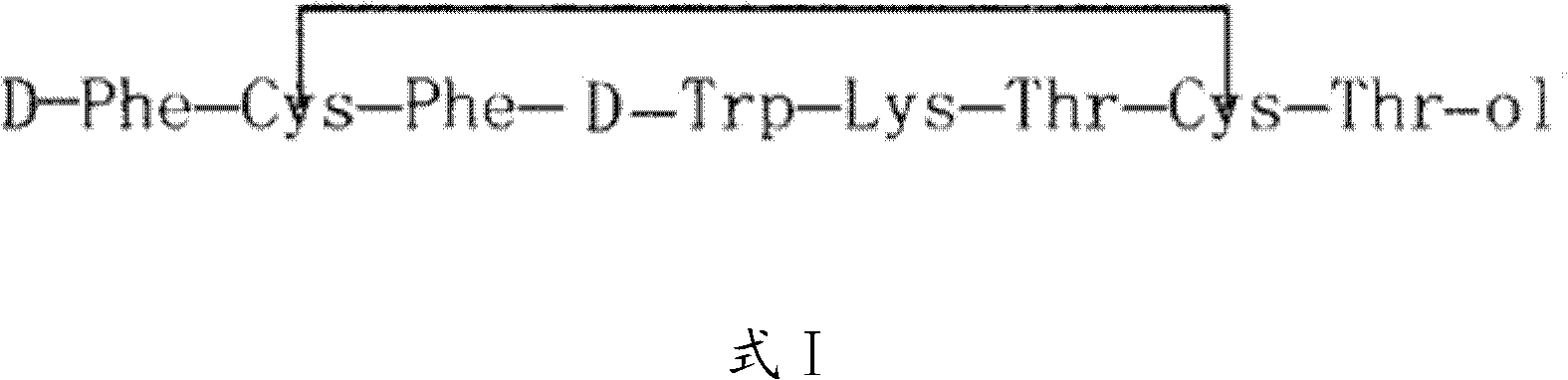

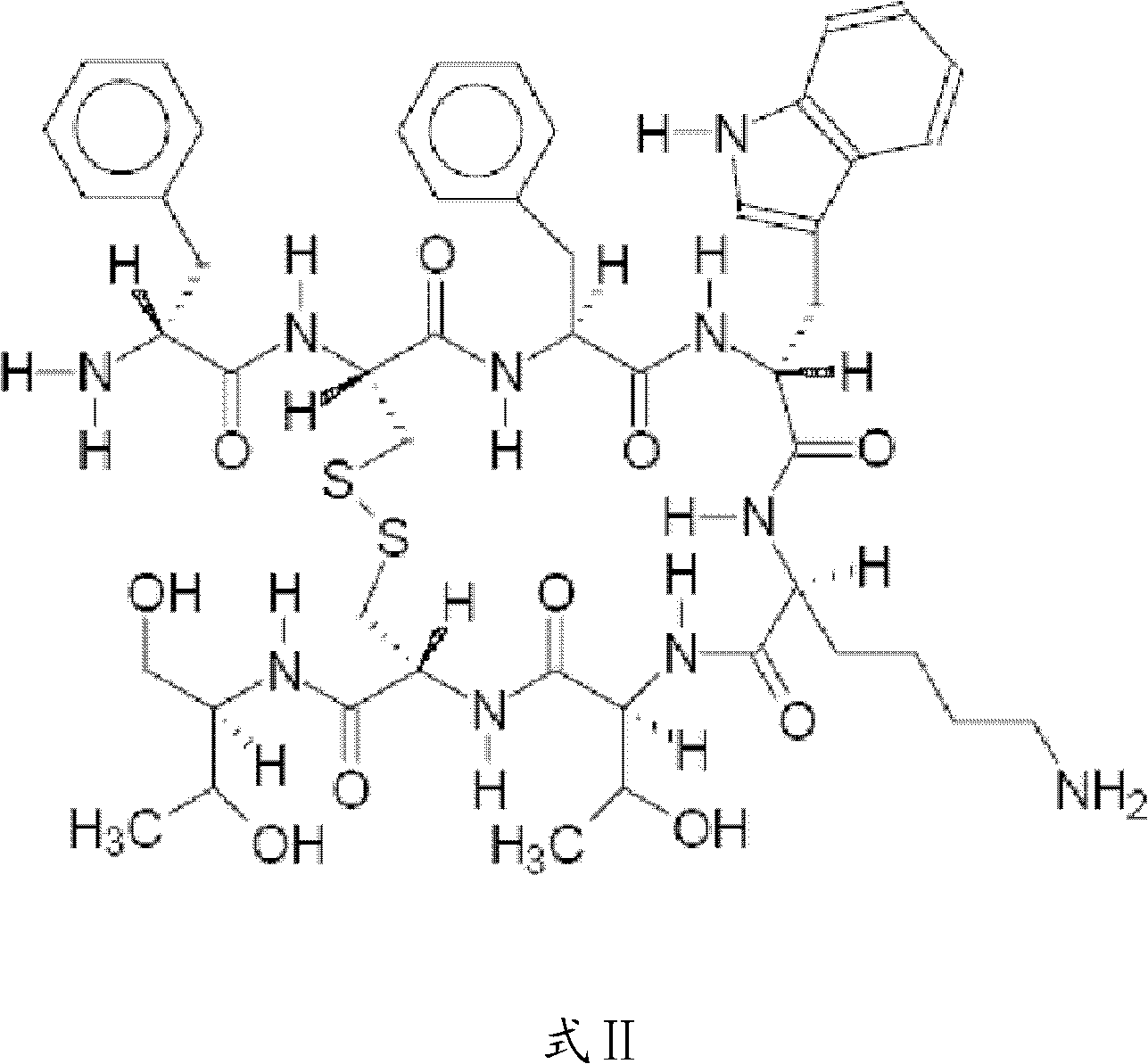

[0035] A preparation method of octreotide, comprising the steps of:

[0036] Step 1: obtaining a dipeptide whose amino acid sequence is D-Phe-Cys;

[0037] Using the resin as a carrier, a hexapeptide re...

Embodiment 1

[0075]Dissolve 107g of Boc-(D)Phe-OH in 800ml of tetrahydrofuran, add 34.8g of HOSU and 62.3g of DCC, dissolve and react at 15°C for 2 hours, TLC detects that the reaction of Boc-(D)Phe-OH is complete, filter Obtain the filtrate; add the filtrate dropwise to the H-Cys(Trt)-OH solution (prepared by adding 5g sodium carbonate and 110g H-Cys(Trt)-OH to 2000ml water), react at 10°C for 15h, and detect Boc-(D) After the Phe-OSU reaction is complete, adjust the pH value of the solution to 3.0 with acetic acid, filter, add 1000ml of ethyl acetate for extraction, wash the ethyl acetate layer with saturated brine for 3 times, then dry with anhydrous sodium sulfate for 4 hours, filter the filtrate Ethyl acetate was distilled off under pressure, crystallized by adding petroleum ether, and dried under pressure to obtain 165.7 g of Boc-(D)Phe-Cys(Trt)-OH with a yield of 99.1%.

[0076] Amino acid activation: according to the molar ratio of Fmoc-AA-OH, HOBT, and DIC ratio of 1:1.2:1.2, the ...

Embodiment 2

[0091] Dissolve 107g of Boc-(D)Phe-OH in 800ml of tetrahydrofuran, add 34.8g of HOSU and 62.3g of DCC, dissolve and react at 10°C for 3 hours, TLC detects that the reaction of Boc-(D)Phe-OH is complete, filter Obtain the filtrate; add the filtrate dropwise to the H-Cys(Trt)-OH solution (prepared by adding 5g sodium carbonate and 110g H-Cys(Trt)-OH to 2000ml water), react at 14°C for 12h, and detect Boc-(D) After the Phe-OSU reaction is complete, adjust the pH value of the solution to 4.0 with acetic acid, filter, add 1000ml ethyl acetate for extraction, wash the ethyl acetate layer with saturated brine three times, then dry it with anhydrous sodium sulfate for 4 hours, filter the filtrate Ethyl acetate was distilled off under pressure, crystallized by adding petroleum ether, and dried under pressure to obtain 166.0 g of Boc-(D)Phe-Cys(Trt)-OH with a yield of 99.3%.

[0092] Amino acid activation: according to the molar ratio of Fmoc-AA-OH, HOBT, and DIC ratio of 1:1.2:1.2, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com