Hard coat agent composition and hard coat film using the same

A technology of hard coating and composition, applied in the field of hard coating objects and hard coating films, can solve the problem that the antifouling effect cannot be expected, and achieve excellent punching processability, excellent wear resistance, and scratch resistance. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0151] As the transparent substrate, a polyethylene terephthalate (PET) film (trade name: COSMOSHINE A-4300, manufactured by Toyobo Co., Ltd.) having a thickness of 75 μm was used.

[0152] (Composition of hard coat agent)

[0153] Component A: 80 parts by weight of dipentaerythritol hexaacrylate

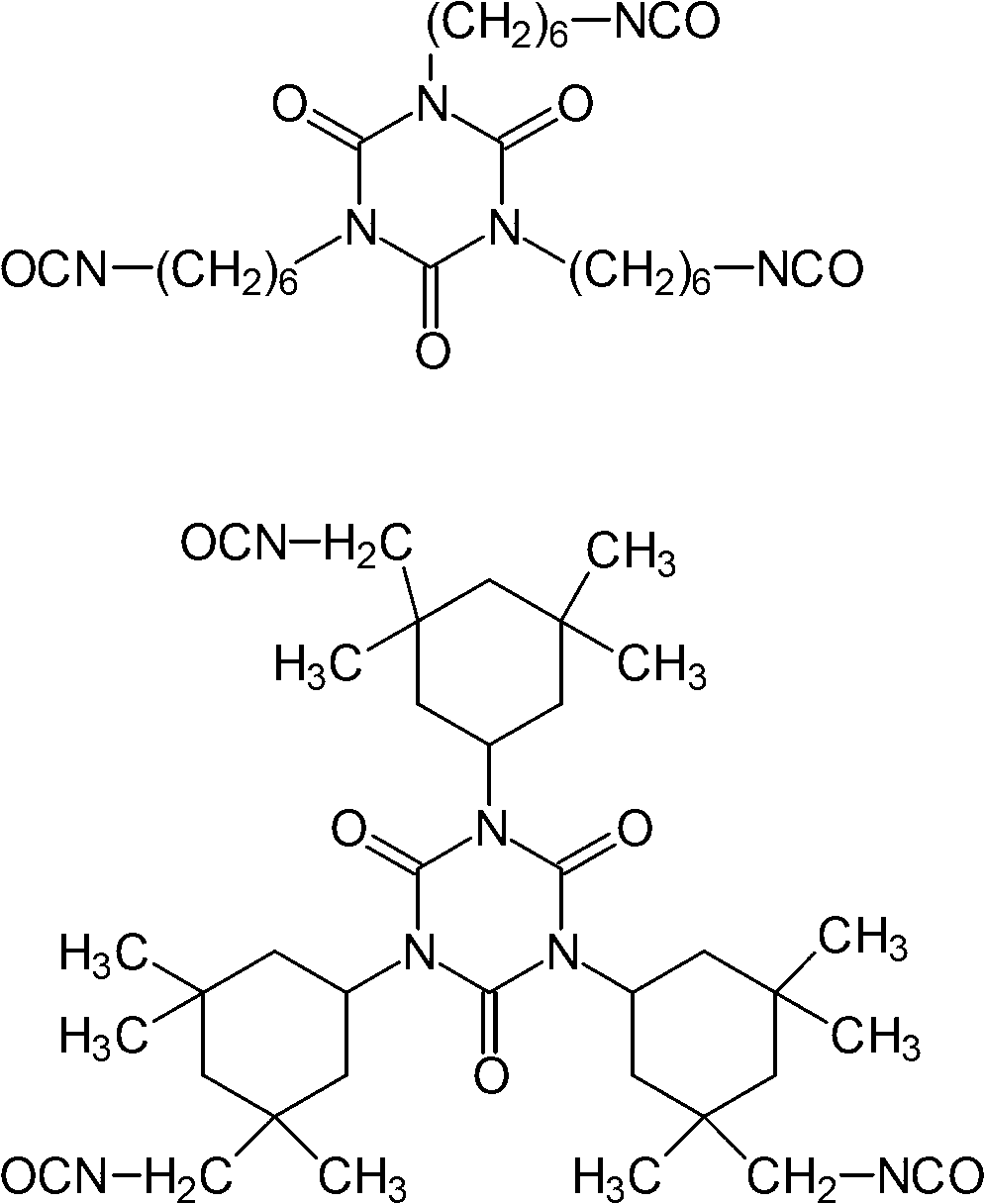

[0154] Component B: 20 parts by weight of urethane acrylate PET-HDI-PET

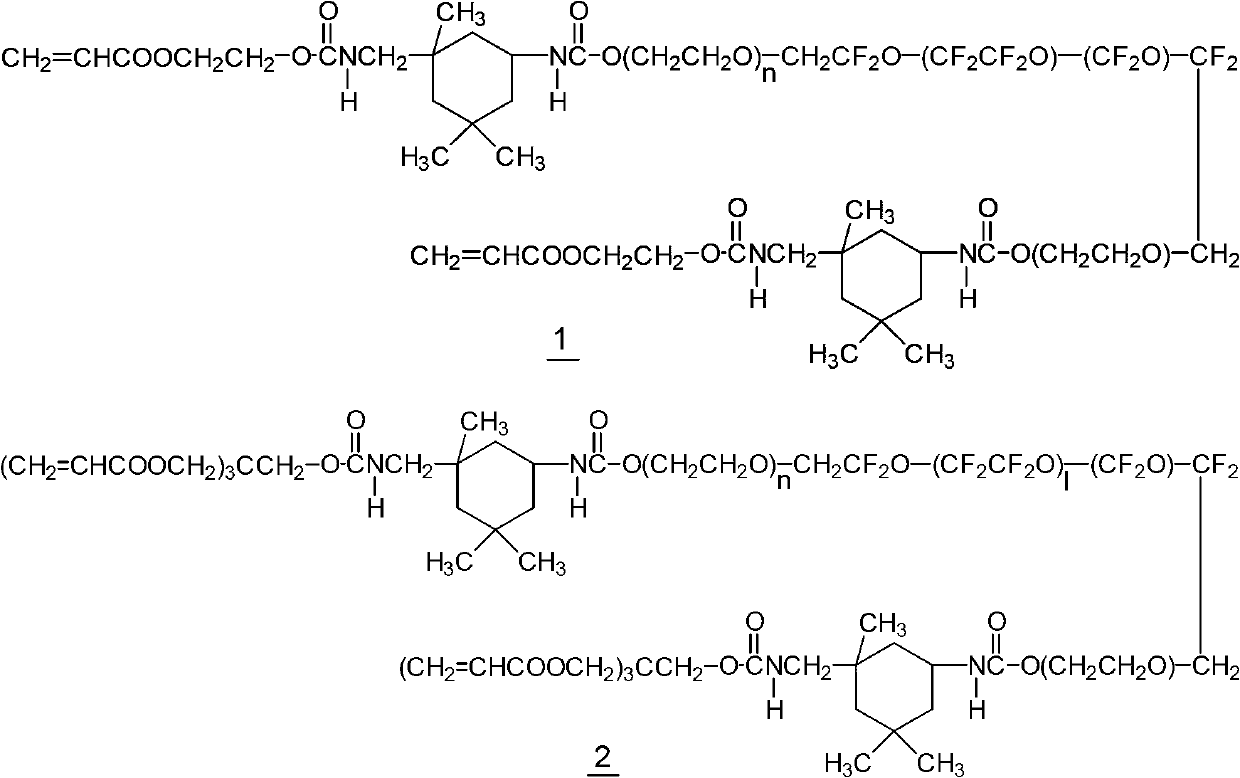

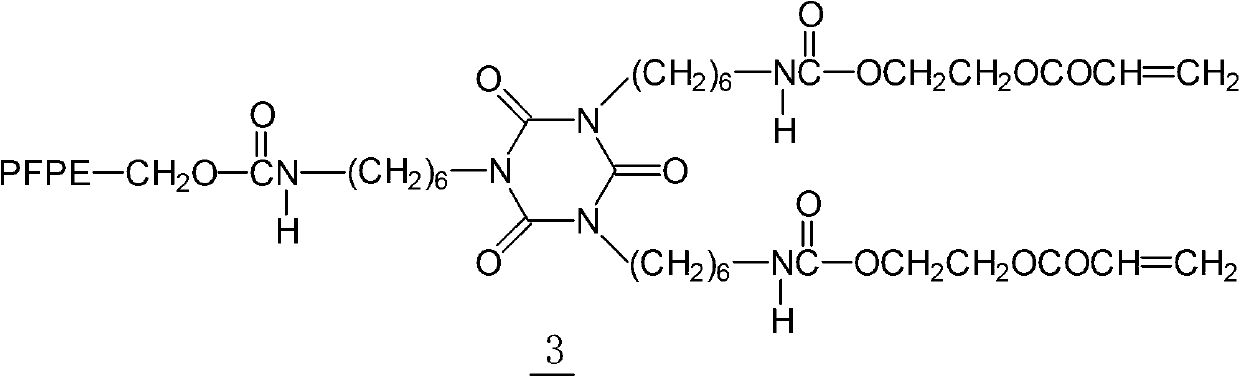

[0155] Component C: 0.05 parts by weight of the above-mentioned fluorinated urethane acrylate

[0156] Component D: 0.02 parts by weight of the above-mentioned fluorinated urethane acrylate 3

[0157] 100 parts by weight of propylene glycol monomethyl ether acetate

[0158] (non-reactive diluent)

[0159] Photopolymerization initiator (1-hydroxycyclohexyl phenyl ketone) 5 parts by weight

[0160] On the surface of the above-mentioned transparent substrate, apply the above-mentioned ultraviolet / electron beam curing type hard coating agent as a coating film by spin coating, and remove the internal impurit...

Embodiment 2

[0162] In addition to using a further reactive group containing 30 parts by weight to modify the silica sol E component (dispersion medium: propylene glycol monomethyl ether acetate, non-volatile components: 40% by weight, with γ-methacryloxypropyl trimethoxy A hard coat layer having a thickness of 10 μm after curing was formed in the same manner as in Example 1, except that silica fine particles were surface-modified with base silane.

[0163] (Composition of hard coat agent)

[0164] Component A: 80 parts by weight of dipentaerythritol hexaacrylate

[0165]Component B: 20 parts by weight of urethane acrylate PET-HDI-PET

[0166] Component C: 0.05 parts by weight of the above-mentioned fluorinated urethane acrylate

[0167] Component D: 0.02 parts by weight of the above-mentioned fluorinated urethane acrylate 3

[0168] E component: Reactive group modified silica sol (dispersion medium: propylene glycol monomethyl ether acetate, non-volatile content: 40% by weight, surfa...

Embodiment 3~10

[0173] As shown in Table 1, a hard coat layer having a thickness of 10 μm after curing was formed in the same manner as in Example 1, except that a hard coat agent having a different compounding composition of components C, D, and E was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com