High performance magnetic core transverse magnetic field heat treatment furnace

A heat treatment furnace, high-performance technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of low performance, and achieve the effect of excellent performance, stable magnetic performance, and bright surface of the magnetic core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

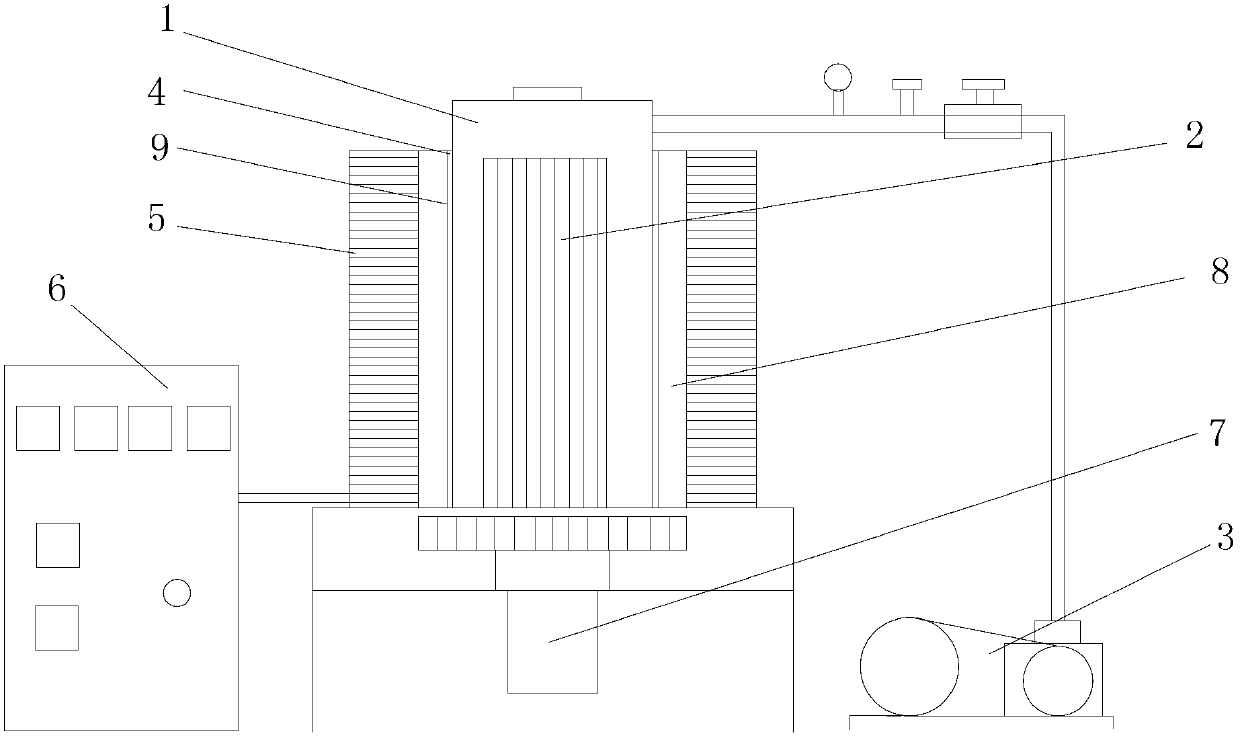

[0016] For heat treatment under the combined conditions of vacuum and transverse magnetic field, the specific steps are as follows: place the magnetic core in the material rack (make the corresponding material rack according to the size of the magnetic core), and put the material rack into the furnace; start the vacuum device and open the vacuum valve , vacuum the inside of the furnace, and keep the vacuum degree at 1×10 -3 -5×10 -3 Pa; open the heating temperature control table, heat the temperature in the furnace to 550~560 degrees of the crystallization temperature; open the magnetizing coil, adjust the current of the magnetizing coil, the magnetic field of the magnetizing coil is: 0~1500Gs; magnetic core heat treatment After completion, the bottom fan can be used to cool the air duct; the heating wire is controlled by a temperature control table, and the cooling rate can be adjusted. When the temperature in the furnace is cooled to below 300 degrees, the treatment is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com