Clothes drying system based on carbon dioxide transcritical heat pump cycle system

A technology of circulation system and drying system, applied in the field of heat pump, can solve the problems of long drying time, exhaust temperature limitation, deterioration of indoor air conditions, etc., and achieve the effect of improving operating efficiency, good temperature matching, and improving operating range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below through specific embodiments and accompanying drawings.

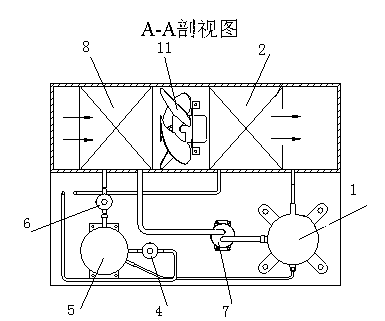

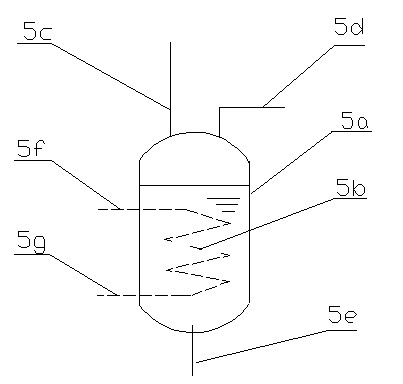

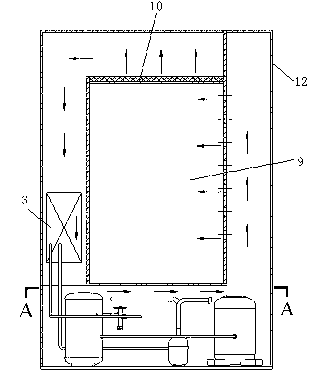

[0029] CO-based 2 Laundry drying system with transcritical heat pump cycle system including CO 2 Transcritical heat pump circulation system, air circulation system, drying room, control system and enclosure with CO installed in the enclosure 2 Transcritical heat pump circulation system, air circulation system and drying chamber, CO 2 The transcritical heat pump circulation system includes a compressor 1, a condenser, a throttling device, an evaporator 8, and a gas-liquid separator 7. The compressor is an inverter compressor. The air circulation system includes a circulation fan 11, a filter device 10 and an air duct, and the circulation fan 11 Is the frequency conversion fan, CO 2 The condenser of the transcritical heat pump cycle system includes a gas cooler 2, a subcooler 3 and a precooler 5, and the throttling device includes a primary throttling device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com