Preparation method of supercapacitor electrode material nickel hydroxide and graphene composite

A technology of supercapacitor and nickel hydroxide, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of low output, unpractical application, complicated process, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

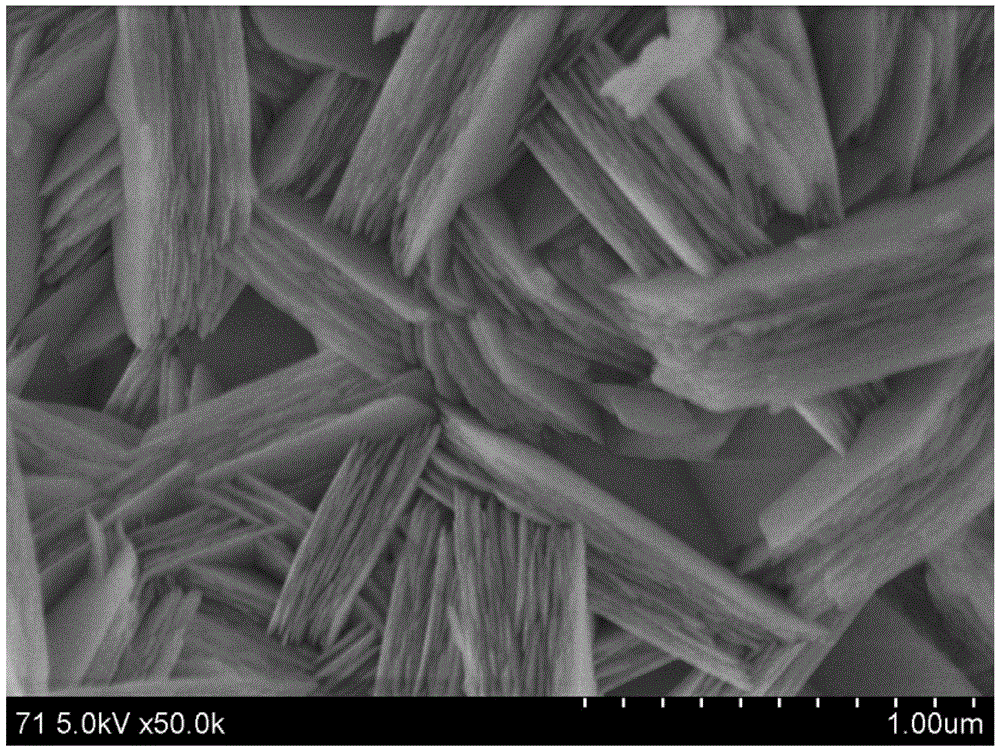

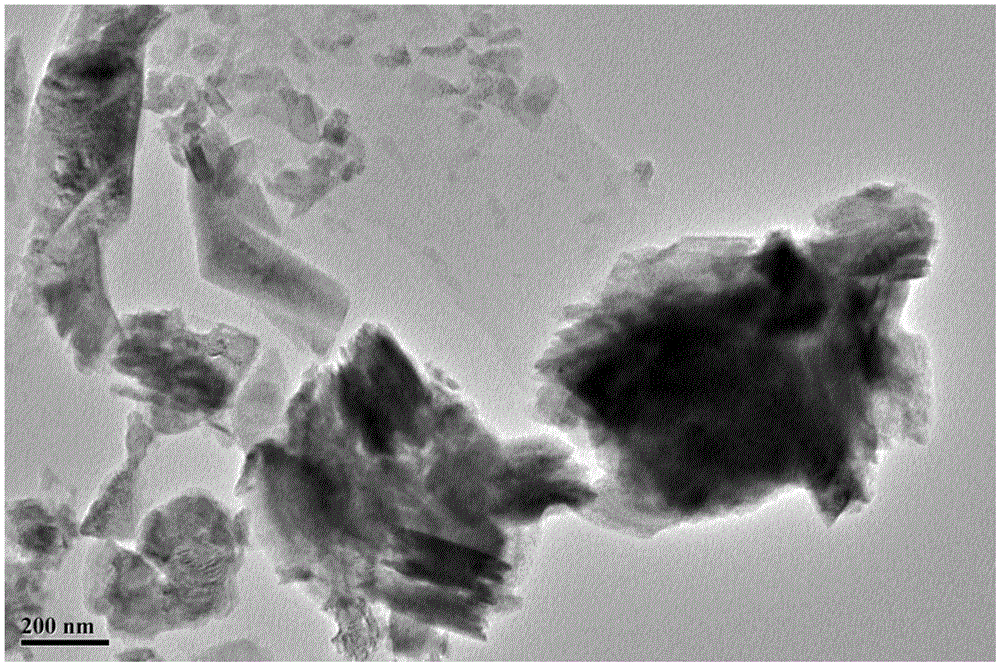

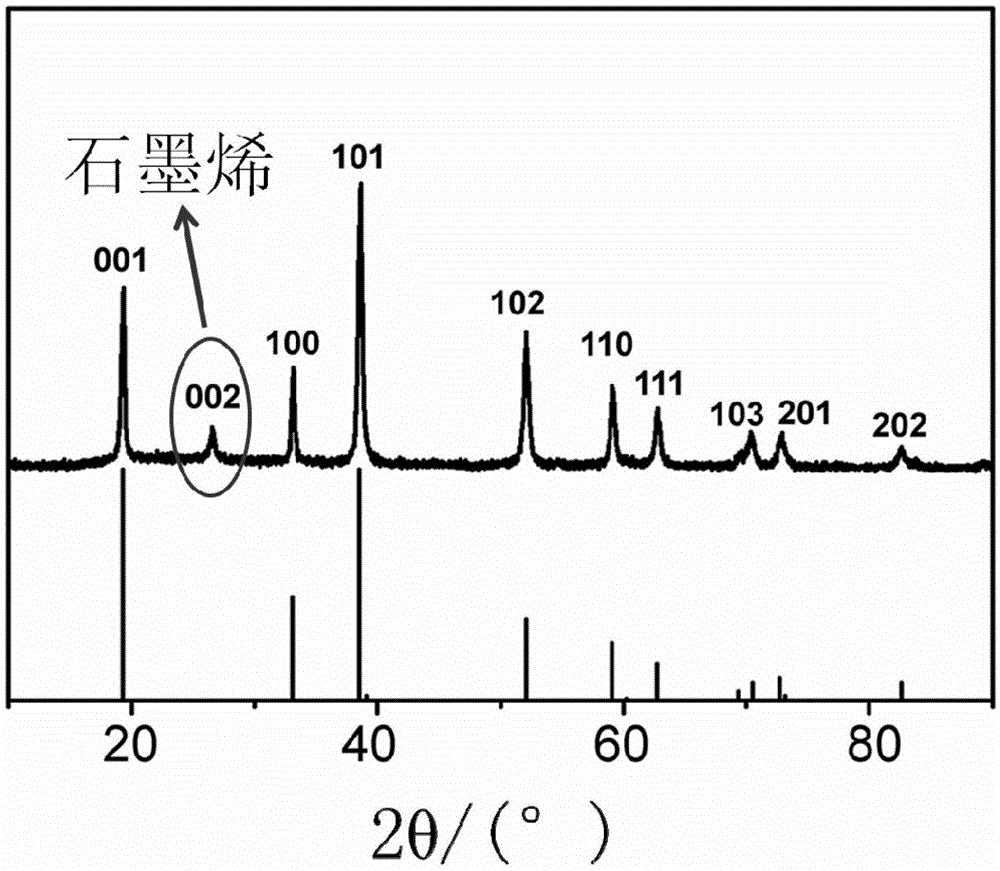

[0023] (1) Add the raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 1mmol and 40ml ethanol, and stir, make mixed solution;

[0024] (2) Add 1ml of 0.2g / ml polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (referred to as P123) aqueous solution to the above solution, and add 1ml of 0.1mg / ml graphene aqueous solution ;

[0025] (3) Heat the above mixed solution to reflux, and add 5ml ammonia water dropwise, the reaction time is 2h;

[0026] (4) After the reaction was completed, the obtained product was centrifuged, washed with deionized water and ethanol solvent, and dried.

Embodiment 2

[0028] (1) Add the raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 0) 5mmol and 40ml ethanol, and stir, make mixed solution;

[0029] (2) Add 10ml of 0.2g / ml polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (referred to as P123) aqueous solution to the above solution, and add 0.1mg / ml graphene aqueous solution 5ml ;

[0030] (3) Heat the above mixed solution to reflux, and add 15ml of ammonia water dropwise, the reaction time is 5h;

[0031] (4) After the reaction was completed, the obtained product was centrifuged, washed with deionized water and ethanol solvent, and dried.

Embodiment 3

[0033] (1) Add the raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 0) 5mmol and 40ml ethanol, and stir, make mixed solution;

[0034] (2) Add 10ml of 0.2g / ml polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (referred to as P123) aqueous solution to the above solution, and add 10ml of 0.1mg / ml graphene aqueous solution ;

[0035] (3) Heat the above mixed solution to reflux, and add 5ml of ammonia water drop by drop, the reaction time is 5h;

[0036] (4) After the reaction was completed, the obtained product was centrifuged, washed with deionized water and ethanol solvent, and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com