Method for treating tobacco leaf processing waste gas and recovering spice

A waste gas treatment and tobacco leaf processing technology, which is applied in the field of cigarette processing, can solve the problems of limited working temperature range, polluted air, easy volatilization, etc., and achieve the effects of wide absorption temperature range, reliable operation and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

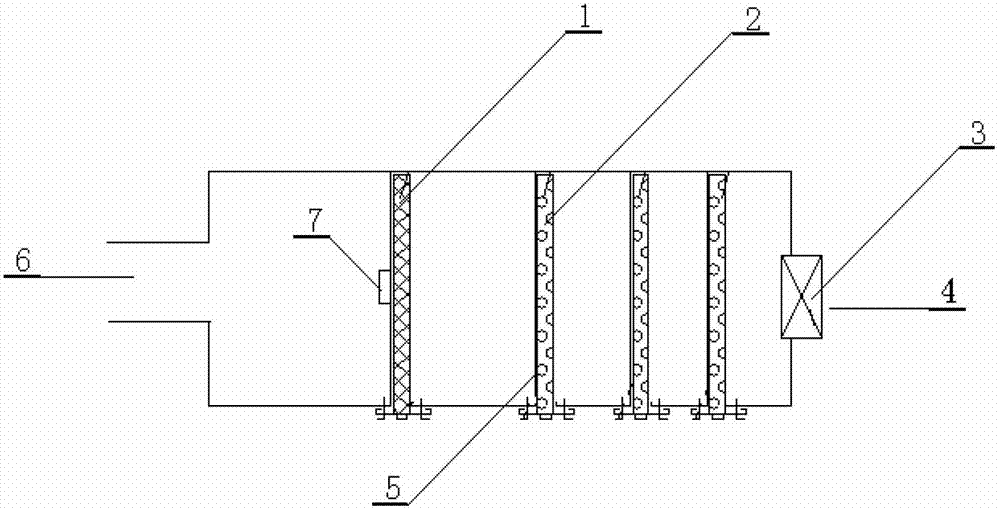

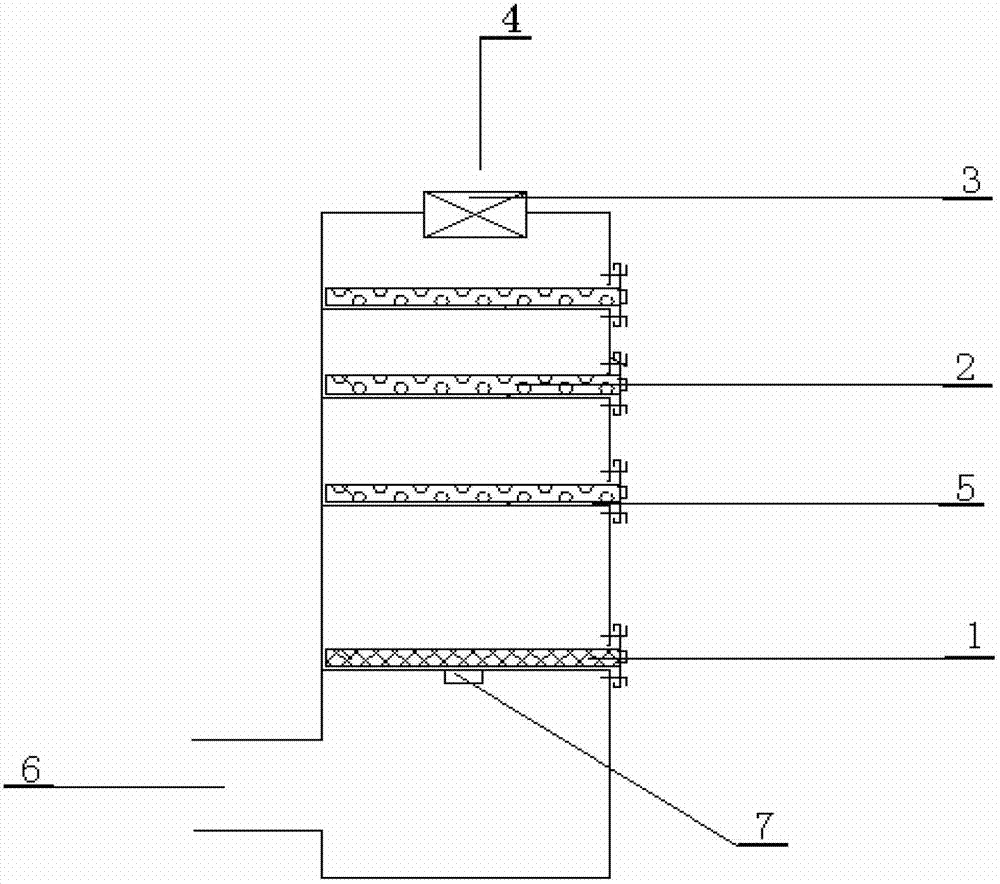

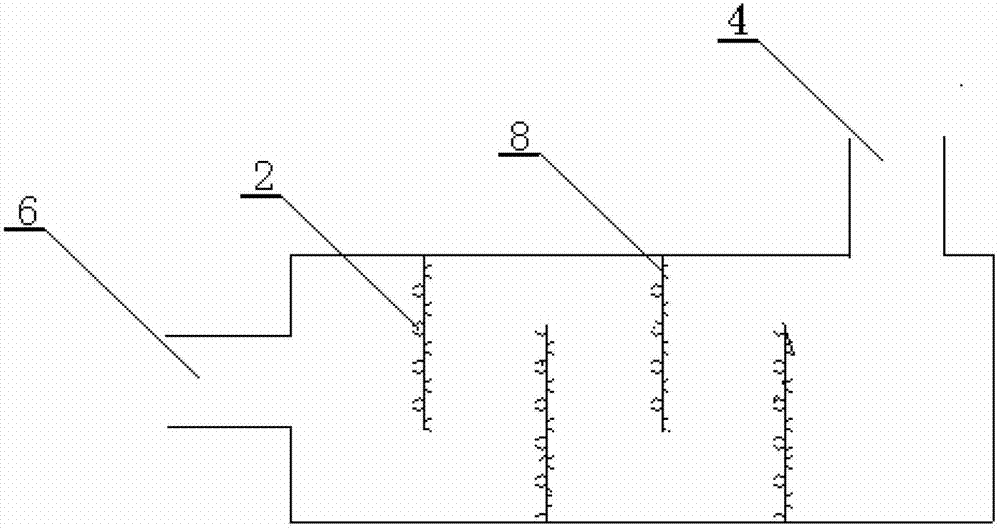

[0027] like figure 1 and figure 2 As shown, the equipment of the present invention for recovering spices from flue-cured tobacco curing and tobacco factory exhaust gas comprises an air inlet 6 and an air outlet 4, an adsorption layer 5 is arranged between the air inlet 6 and the air outlet 4, and the adsorption layer 5 is made of anhydrous Sodium sulfate, sponge, quartz sand, glass fiber, carbon fiber cotton, activated carbon, macroporous resin, silica gel, calcium chloride and cellulose acetate absorbent 2 form the equipment for recovering spices, and the absorbent 2 can be extracted together with the adsorption layer 5, To facilitate pick-and-place and replacement; between the air inlet 6 and the adsorption layer 5, there is a dust removal net 1 for filtering dust particles, and a vibrator 7 is arranged on the dust removal net 1; an induced draft fan 3 is arranged at the air outlet 4, so as to avoid affecting the normal operation of the original equipment Out of the wind. ...

Embodiment 2

[0029] Install such as figure 2 The vertical absorption equipment is designed to be 2.2m high, 1m wide, and 0.5m thick, and each of the three sets of equipment uses 30kg of absorbent. The absorbent is composed of 4% anhydrous sodium sulfate, 4% sponge, 2% quartz sand, 5% glass fiber, 13% carbon fiber cotton, 42% activated carbon, 2% macroporous resin, 18% silica gel, and calcium chloride according to the percentage by weight. 9% and 1% cellulose acetate. About 3,500kg of fresh tobacco leaves are roasted in each oven, the working environment temperature of the absorbent is 25°C-60°C, and the flow velocity of the exhaust gas is 100,000 m 3 ~120000m 3 / Hour. After 14 hours of absorption, retrieve the absorbent. The recovered absorbent is eluted through an alcohol gradient with a concentration of more than 95% at normal temperature and pressure, then the absorbent is centrifuged and dried at 2000 rpm for 1-2 minutes, and the eluate is treated with molecular distillation and e...

Embodiment 3

[0031] Two sets of absorption equipment are placed in the leaf roasting settling chamber on the top floor of the leaf threshing and redrying workshop. The absorption equipment is designed as follows: figure 2 The vertical absorption equipment shown is 1.2m high, 0.6m wide, and 0.4m thick. Each set of equipment is put into about 20kg of absorbent. The absorbent consists of 2% sodium sulfate water, 2% sponge, 1% quartz sand, glass 2% fiber, 15% carbon fiber cotton, 50% activated carbon, 2% macroporous resin, 16% silica gel, 9% calcium chloride and 1% cellulose acetate. The temperature of the absorbent is 60°C-80°C, and the flow velocity of the exhaust gas is 80,000 m 3 ~100000m 3 / h. After 3.5 hours of absorption, retrieve the absorbent. The recovered absorbent is eluted through an alcohol gradient with a concentration of more than 95% at normal temperature and pressure, then the absorbent is centrifuged and dried at 2500 rpm for 4-5 minutes, and the eluate is treated with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com