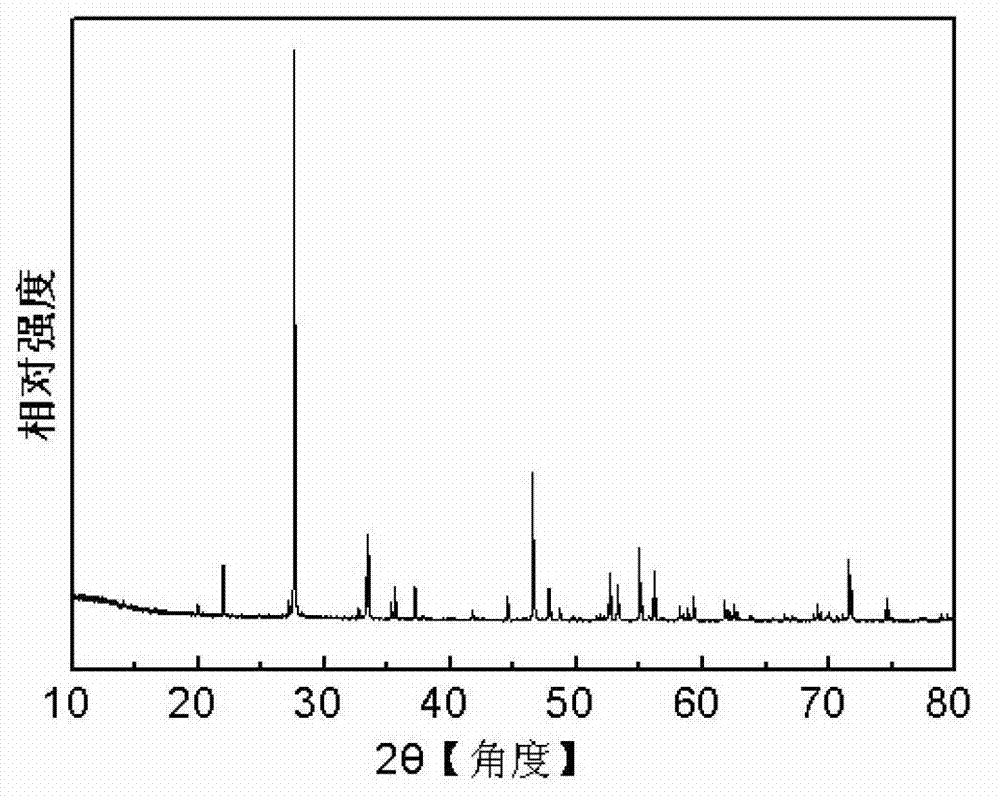

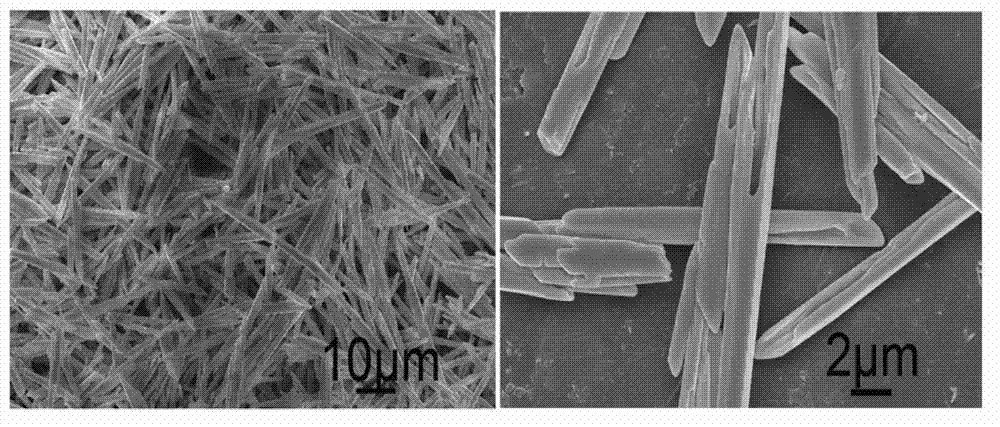

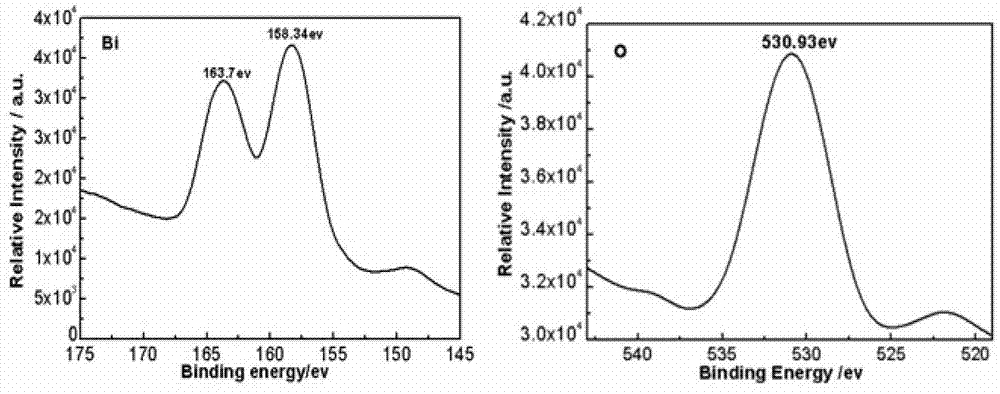

Bismuth trioxide nanotubes prepared by microwave-assisted liquid-phase process and application thereof

A bismuth trioxide, microwave-assisted technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unreported tetracycline wastewater, reduce energy consumption and reaction costs, The effect of easy mass production and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a kind of microwave-assisted liquid phase method to prepare bismuth trioxide (Bi 2 o 3 ) method for nanotubes, according to the following steps:

[0032] A. Weigh 0.95g of Bi(NO 3 ) 3 ·5H 2 O and 0.45g Na 2 SO 4 , dissolved in 40mL deionized water, sonicated and magnetically stirred for 1 hour to form a mixed solution;

[0033] B. Weigh 0.70g of NaOH, add 40mL of deionized water, and ultrasonically disperse it evenly to form a transparent sodium hydroxide solution;

[0034] C, the transparent sodium hydroxide solution obtained in step B is added dropwise to the mixed solution obtained in step A under magnetic stirring;

[0035]D. Transfer the solution obtained in step C to a quartz container with a capacity of 100mL, place it in a microwave reactor with a microwave power of 800W, heat up to 80°C for 10min, cool naturally, and collect the product;

[0036] E, the product obtained in step D is centrifuged, washed three times with deionized...

Embodiment 2

[0039] This embodiment provides a kind of microwave-assisted liquid phase method to prepare bismuth trioxide (Bi 2 o 3 ) method for nanotubes, according to the following steps:

[0040] A. Weigh 1.00g of Bi(NO 3 ) 3 ·5H 2 O and 0.50 g Na 2 SO 4 , dissolved in 40mL deionized water, sonicated and magnetically stirred for 1 hour to form a mixed solution;

[0041] B. Weigh 0.75g of NaOH, add 40mL of deionized water, and ultrasonically disperse it evenly to form a transparent sodium hydroxide solution;

[0042] C, the transparent sodium hydroxide solution obtained in step B is added dropwise to the mixed solution obtained in step A under magnetic stirring;

[0043] D. Transfer the solution obtained in step C to a quartz container with a capacity of 100mL, place it in a microwave reactor with a microwave power of 800W, heat up to 100°C for 20min, cool naturally, and collect the product;

[0044] E, the product obtained in step D is centrifuged, washed three times with deioni...

Embodiment 3

[0047] This embodiment provides a kind of microwave-assisted liquid phase method to prepare bismuth trioxide (Bi 2 o 3 ) method for nanotubes, according to the following steps:

[0048] A. Weigh 0.95g of Bi(NO 3 ) 3 ·5H 2 O and 0.45g Na 2 SO 4 , dissolved in 40mL deionized water, sonicated and magnetically stirred for 1 hour to form a mixed solution;

[0049] B. Weigh 0.75g of NaOH, add 40mL of deionized water, and ultrasonically disperse it evenly to form a transparent sodium hydroxide solution;

[0050] C, the transparent sodium hydroxide solution obtained in step B is added dropwise to the mixed solution obtained in step A under magnetic stirring;

[0051] D. Transfer the solution obtained in step C to a quartz container with a capacity of 100mL, place it in a microwave reactor with a microwave power of 800W, heat up to 100°C for 20min, cool naturally, and collect the product;

[0052] E, the product obtained in step D is centrifuged, washed three times with deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com