Method for improving optical property of high Mn-doped quantum dot

A technology of optical properties and quantum dots, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of defect luminescence, limited doping amount, low luminous efficiency of quantum dots, etc., achieve small size, improve optical properties, and optimize selection Ligand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

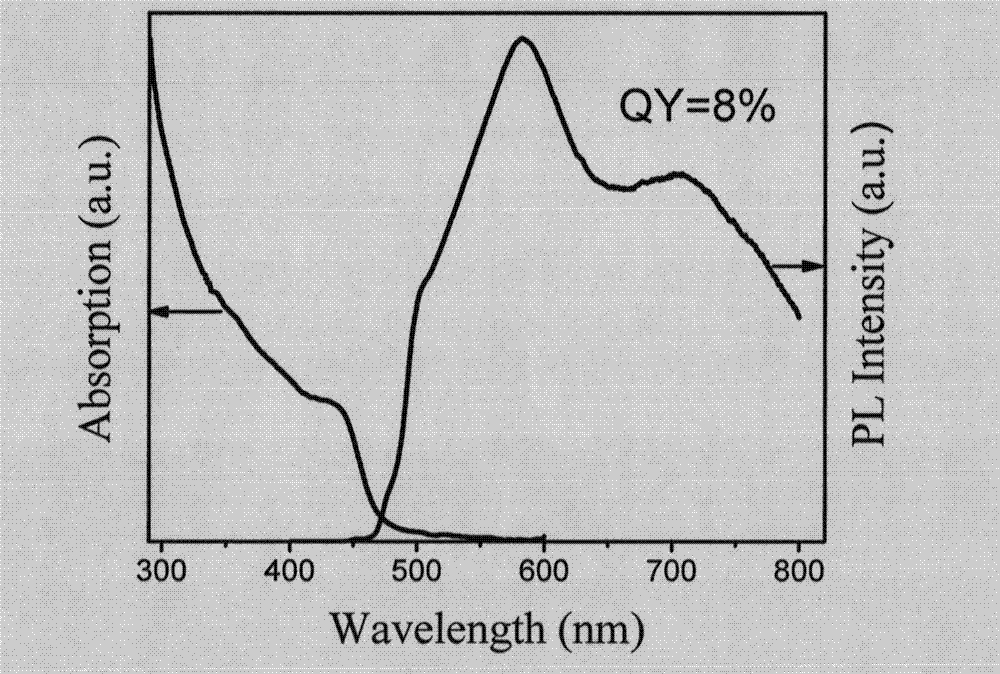

Embodiment 1

[0041] Weigh 0.03g (0.05mmol) manganese stearate (MnSt 2 ) and measure 12mL of octadecene (ODE) into a 100mL three-necked bottle. The high-purity argon atmosphere in the bottle is ensured by repeated vacuuming and recirculation of argon. Raise the temperature from room temperature to 110°C for 20 minutes to remove the gas in the bottle, and then raise the temperature to 260°C. The sulfur (S) precursor solution (containing 1.5 mmol S powder, 3 mL ODE, and 0.2 mL dodecanethiol (DDT)) was quickly injected into the three-necked flask at 260 °C to generate MnS crystal nuclei. After injecting S, the temperature is rapidly lowered to 150°C to stop the MnS crystal nucleus from continuing to grow, and then the temperature is rapidly raised to 230°C. At this temperature, 7 mL of cadmium precursor solution (containing 1 mmol cadmium stearate (CdSt 2 ) and 7mL ODE) were added to the reaction solution to obtain MnS / CdS quantum dots without a ZnS transition layer. Finally, the solution ...

Embodiment 2

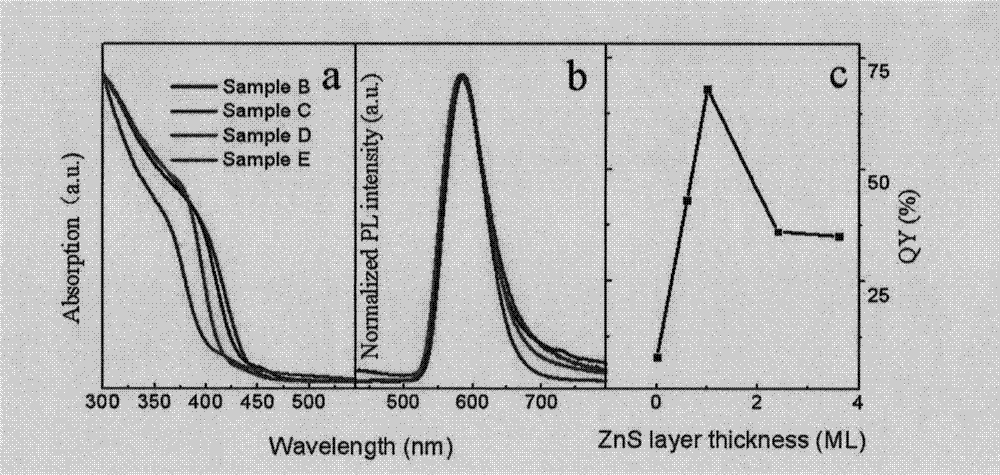

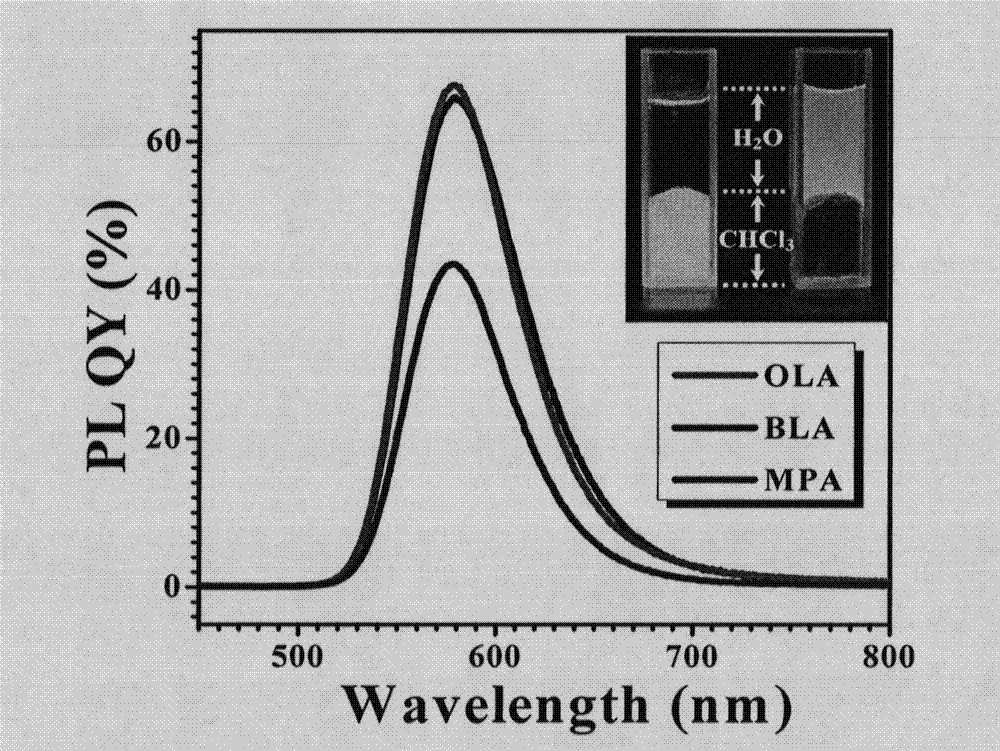

[0043] Weigh 0.03g (0.05mmol) MnSt 2 And measure 12mL ODE into a 100mL three-necked bottle. The high-purity argon atmosphere in the bottle is ensured by repeated vacuuming and recirculation of argon. Raise the temperature from room temperature to 110°C for 20 minutes to remove the gas in the bottle, and then raise the temperature to 260°C. The S precursor solution (containing 1.5 mmol S, 3 mL ODE, and 0.2 mL DDT) was quickly injected into the three-neck flask at 260 °C to generate MnS crystal nuclei. After injecting S, the temperature is rapidly lowered to 150°C to stop the MnS crystal nuclei from continuing to grow, and then the temperature is raised to 260°C. 3 mL of zinc precursor solution (containing 0.05 mmol of zinc stearate (ZnSt 2 ), 0.6mL oleylamine (OLA) and 1mL ODE) were slowly injected into the three-neck flask, and kept at 260°C for 10min to obtain MnS / ZnS quantum dots. Then 6 mL of cadmium precursor solution (containing 0.95 mmol CdSt 2 and 6mL ODE) were add...

Embodiment 3

[0045] Weigh 0.03g (0.05mmol) MnSt 2 And measure 12mL ODE into a 100mL three-necked bottle. The high-purity argon atmosphere in the bottle is ensured by repeated vacuuming and recirculation of argon. Raise the temperature from room temperature to 110°C for 20 minutes to remove the gas in the bottle, and then raise the temperature to 260°C. The S precursor solution (containing 1.5 mmol S, 3 mL ODE, and 0.2 mL DDT) was quickly injected into the three-neck flask at 260 °C to generate MnS crystal nuclei. After injecting S, the temperature is rapidly lowered to 150°C to stop the MnS crystal nucleus from continuing to grow, and then the temperature is rapidly raised to 260°C. 3 mL of zinc precursor solution (containing 0.1 mmol ZnSt 2 , 0.6mL OLA and 3mL ODE) were slowly injected into the three-neck flask, and kept at 260°C for 10min to obtain MnS / ZnS quantum dots. Then 7 mL of cadmium precursor solution (containing 1 mmol CdSt 2 and 7mL ODE) in four times (respectively 1mL, 2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com