Coal-based needle coke preparation process

A process method and technology of preparation process, which are used in coke ovens, petroleum industry, coking carbon-containing materials, etc., can solve the problems of small processing capacity and unsatisfactory purification effect, and achieve the effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

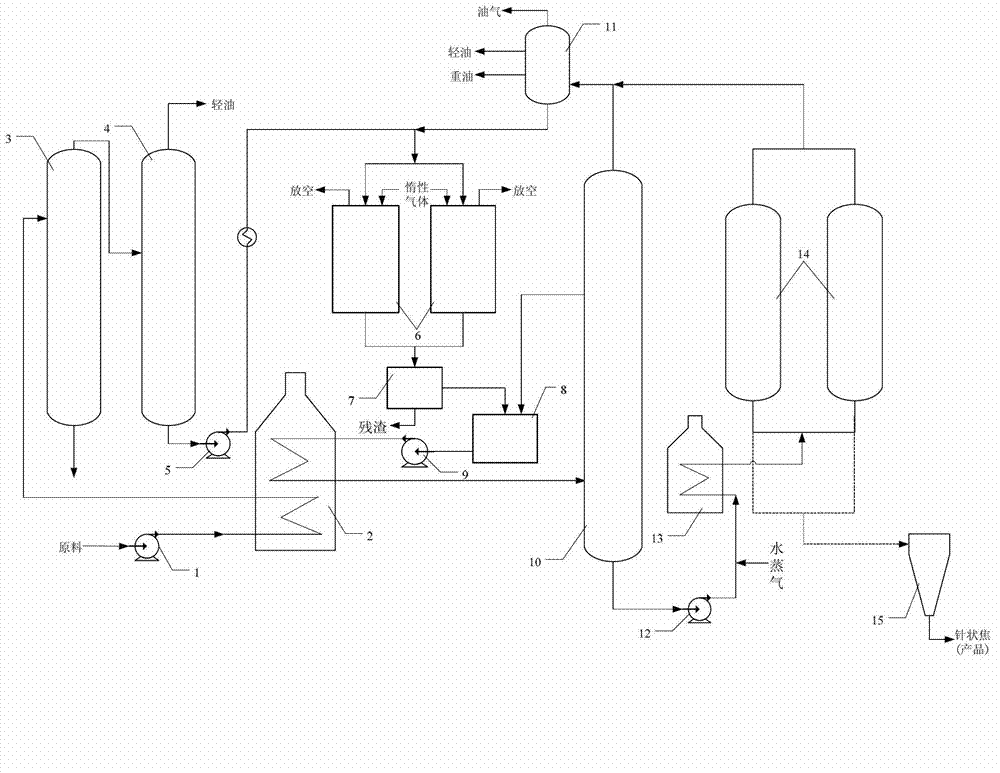

Embodiment 1

[0052] The raw coal tar is heated by the 1# tubular heating furnace 2 and enters the 1# flash tower 3, the feed temperature is 400°C, the vacuum degree at the top of the tower is 10KPa, the empty tower flow velocity is 0.5m / s, and the escaping from the top of the tower is The flash oil enters the 2# flash tower, the feed temperature is 340°C, and the vacuum degree at the top of the tower is 50KPa. The refined asphalt raw material obtained is sent to the pressurized hot filter kettle 6, and the feed inlet temperature is 150°C. It is composed of diatomite and stainless steel filter. The particle size of diatomite is 50 mesh, the stainless steel filter is 500 mesh, and the thickness of the filter layer is 5 cm. Inject N 2 , pressurized to 0.5MPa, the filtrate after hot filtration enters the three-legged centrifuge 7, the filter cloth mesh number of the centrifuge is 1600 mesh, and is centrifugally filtered at a speed of 2000 rpm, and the obtained refined purified asphalt quinoline...

Embodiment 2

[0054] The raw coal tar pitch is heated by the 1# tubular heating furnace 2 and then enters the 1# flash tower 3, the feed temperature is 490°C, the vacuum degree at the top of the tower is 50KPa, the empty tower flow rate is 1m / s, and the flash tower escapes from the top of the tower Distilled oil enters the 2# flash distillation tower, the feed temperature is 400°C, and the vacuum degree at the top of the tower is 90KPa. The obtained refined asphalt raw material is sent to the pressurized hot filter kettle 6, and the feed inlet temperature is 240°C. It is made of a mixture of diatomite and expanded perlite and a stainless steel filter. Diatomite crushed to 100 mesh and expanded perlite crushed to 100 mesh is mixed at a mass ratio of 1:1. The mesh of the stainless steel filter is 700 mesh. The layer thickness is 8 centimeters, inject Ar, pressurize to 2MPa and the hot filtered filtrate enters in the three-legged centrifuge 7, and the filter cloth mesh number of the centrifuge ...

Embodiment 3

[0056] The raw material is remixed with soft asphalt and heated by 1# tubular heating furnace 2, and then enters 1# flash tower 3, the feed temperature is 450°C, the vacuum degree at the top of the tower is 90KPa, the empty tower flow rate is 2m / s, and the top of the tower escapes The flash oil enters the 2# flash tower, the feed temperature is 380°C, and the vacuum degree at the top of the tower is 130KPa. The refined asphalt raw material obtained is sent to the pressurized hot filter kettle 6, and the temperature of the feed inlet is 200°C. The layer is composed of expanded perlite and stainless steel filter mesh, the particle size of expanded perlite particles is 200 mesh, the mesh number of stainless steel filter mesh is 600 mesh, and the thickness of the filter layer is 10 cm. 2 , pressurized to 1MPa, the filtrate after hot filtration enters the three-legged centrifuge 7, the filter cloth mesh number of the centrifuge is 900 mesh, and is centrifugally filtered at a speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com