Rare-earth-containing 34Mn2V high-pressure gas bottle blank and production method thereof

A technology for a high-pressure gas cylinder and a production method, which is applied in the field of iron and steel metallurgy, and can solve the problems of repeated filling of gas cylinders, high fluidity, poisoning, and concurrent fires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

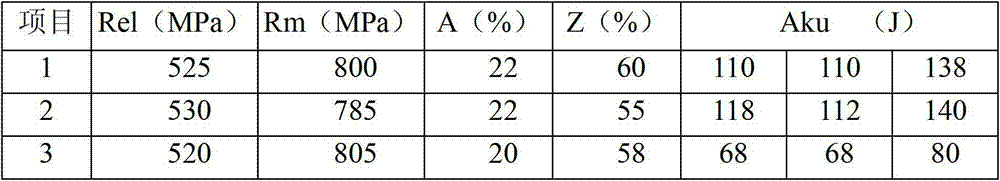

Examples

Embodiment 1

[0015] Rare earth is added into ladle molten steel according to 0.005% of molten steel weight. "Blast furnace molten iron - molten iron pretreatment - converter smelting - LF refining - VD vacuum degassing - calcium treatment - adding rare earth - bloom continuous casting - rolling 200mm × 200mm finished billet - sampling - sample heat treatment - inspection" containing rare earth 34Mn2V high-pressure gas preform production process.

[0016] The variety and form of adding trace rare earth is feed rare earth composite cored wire.

[0017] The timing of adding trace rare earths to ladle molten steel is after calcium treatment to ensure soft blowing of argon for 5 minutes.

[0018] See Table 1 for the chemical composition (Wt%) of the 34Mn2V high-pressure gas bottle blank (200mm×200mm).

[0019] The finished billet of 200mm×200mm is rolled at a heating temperature of 1180±20°C, a rolling start temperature of 1160±20°C, and a final rolling temperature of 920±20°C.

[0020] The ...

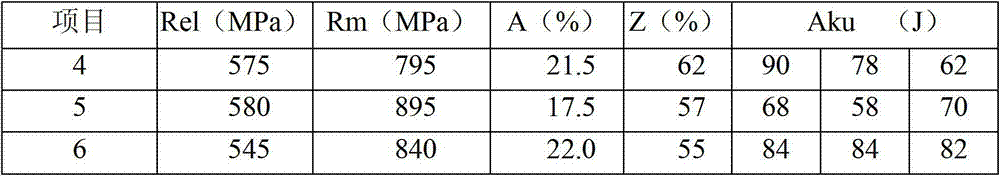

Embodiment 2

[0029] Mixed rare earths are added into ladle molten steel according to 0.0075% of the weight of molten steel. "Blast furnace molten iron - molten iron pretreatment - converter smelting - LF refining - VD vacuum degassing - calcium treatment - adding rare earth - bloom continuous casting - rolling 200mm × 200mm finished billet - sampling - sample heat treatment - inspection" containing rare earth 34Mn2V high-pressure gas preform production process.

[0030] The variety form of adding trace rare earth is silicon aluminum barium calcium rare earth iron alloy.

[0031] The timing of adding trace rare earths to ladle molten steel is to add trace rare earths after calcium treatment to ensure soft blowing of argon for 4 minutes. The chemical composition (Wt%) of 34Mn2V molten steel is shown in Table 4.

[0032] The finished billet of 200mm×200mm is rolled at a heating temperature of 1180±20°C, a rolling start temperature of 1160±20°C, and a final rolling temperature of 920±20°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com