Ceramic membrane cleaning agent

A ceramic membrane and cleaning agent technology, applied in the field of cleaning agents, can solve the problems of unfavorable environmental protection, low cleaning efficiency, and low cleaning efficiency, and achieve the effects of reducing chemical consumption, high cleaning efficiency, and shortening cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

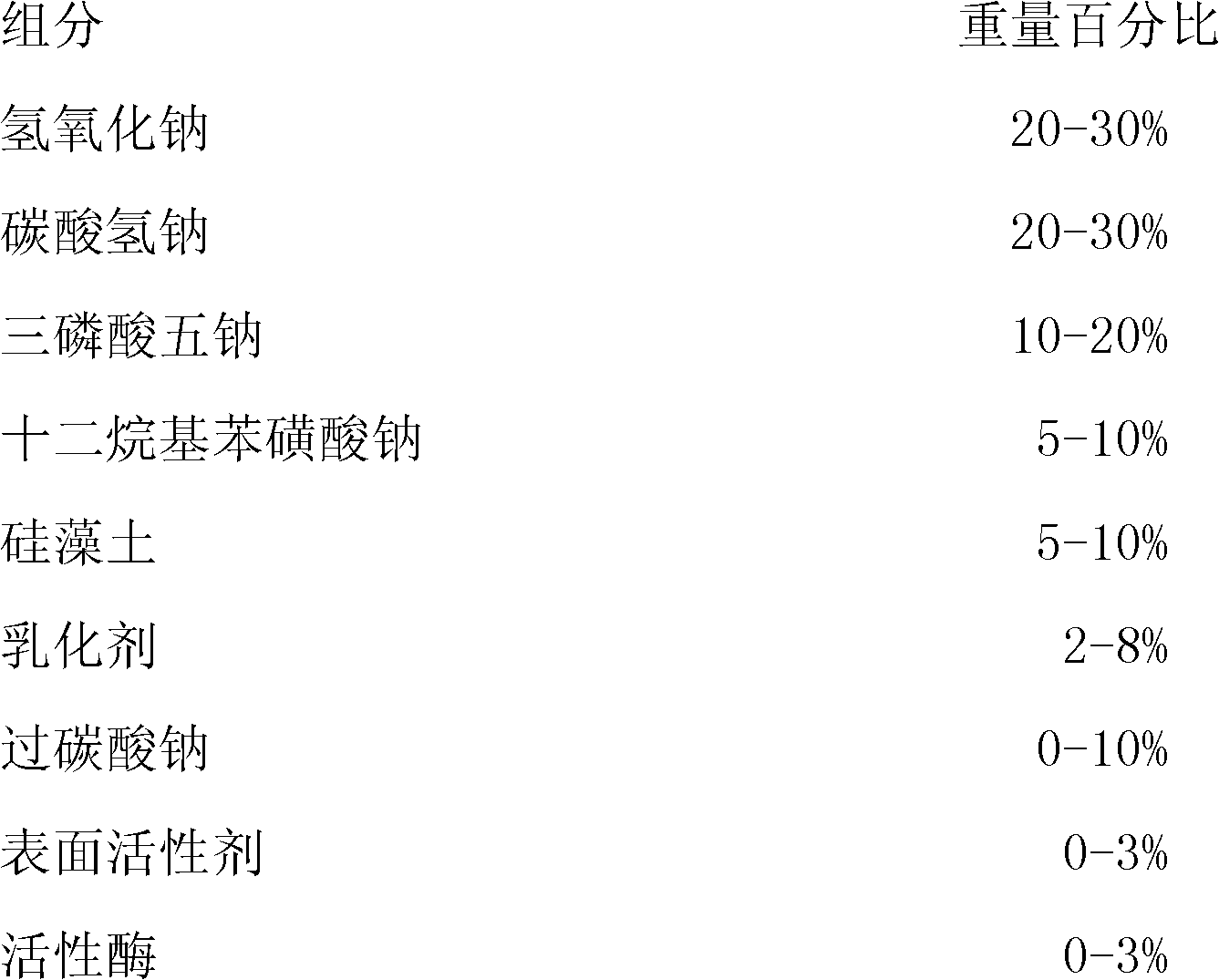

[0035] The cleaning agent for ceramic membrane of the present embodiment is formed by mixing the following components by weight percentage:

[0036]

[0037] It should be pointed out that the present invention mainly utilizes the emulsifying effect generally possessed by emulsifiers to ensure the cleaning effect, therefore, each embodiment of the present invention can use any emulsifier in the prior art. The applicant has found through research that when the emulsifier is at least one of sodium stearate and sodium lauryl sulfate, a better cleaning effect can be achieved, which can be used as a preferred technical means.

[0038] The cleaning agent of this embodiment is a powder easily soluble in water.

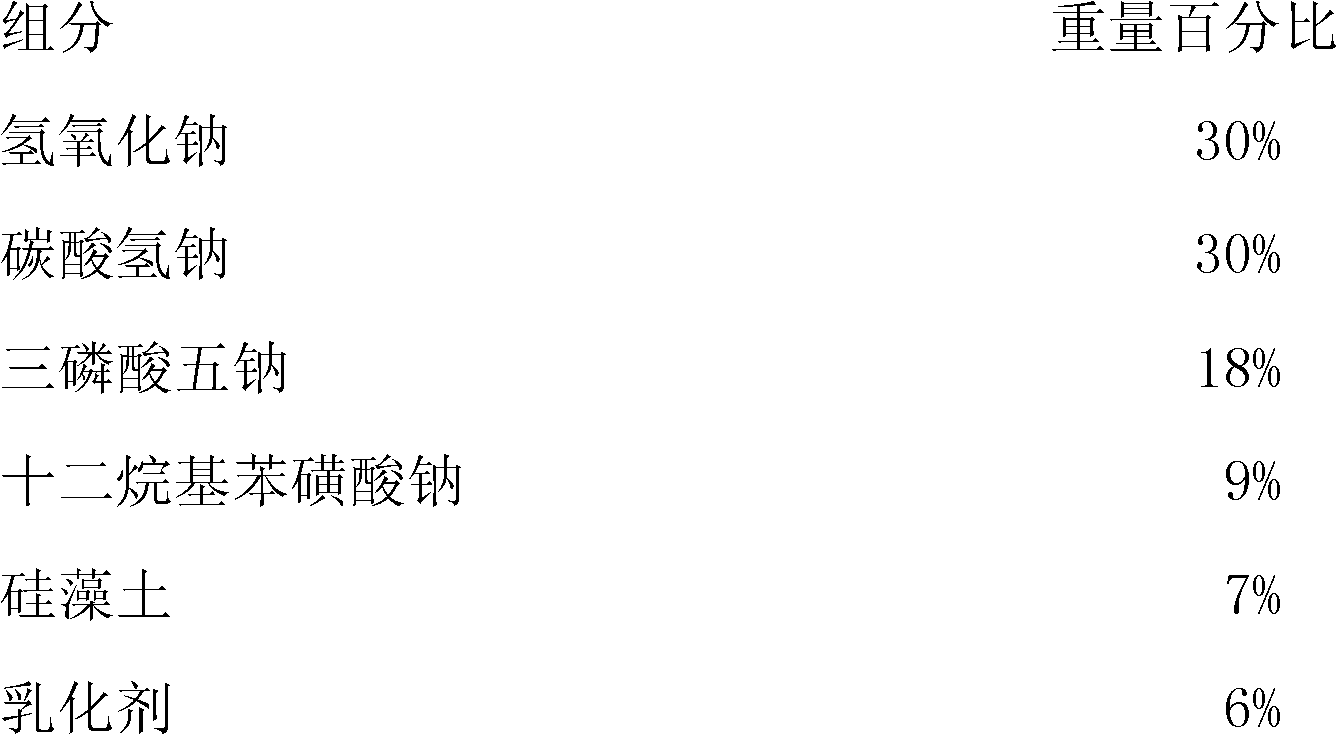

[0039] The preparation method of the cleaning agent of this embodiment comprises the following steps: adding 30% sodium hydroxide, 30% sodium bicarbonate, 18% pentasodium triphosphate, 9% dodecane in the corrosion-resistant reactor Sodium phenyl sulfonate, 7% diatomaceous ...

Embodiment 2

[0047] The cleaning agent for ceramic membrane of the present embodiment is formed by mixing the following components by weight percentage:

[0048]

[0049] The emulsifier is preferably at least one of sodium stearate and sodium lauryl sulfate.

[0050] The cleaning agent of this embodiment is a powder easily soluble in water.

[0051] The preparation method of the cleaning agent of the present embodiment comprises the following steps: adding 28.5% sodium hydroxide, 22% sodium bicarbonate, 14.5% pentasodium triphosphate, 8% dodecane in the corrosion-resistant reactor Sodium phenyl sulfonate, 10% diatomaceous earth, 7% emulsifier, 10% sodium percarbonate; grind evenly to obtain ceramic membrane cleaning agent.

[0052] The purposes of present embodiment cleaning agent are identical with embodiment 1.

[0053] The cleaning method of the ceramic membrane using the cleaning agent of this embodiment is the same as that of Embodiment 1.

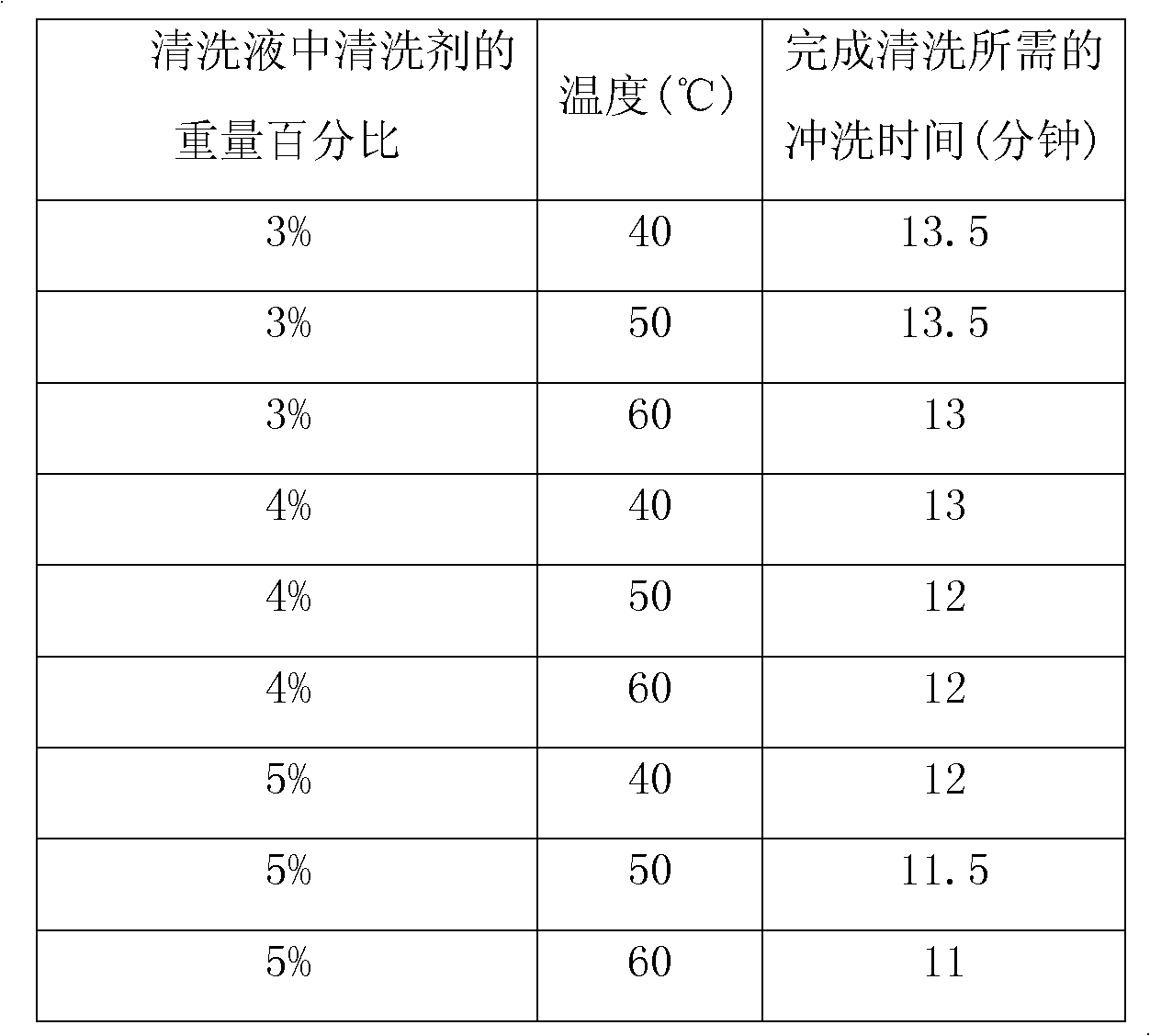

[0054] The cleaning experiment data i...

Embodiment 3

[0057] The cleaning agent for ceramic membrane of the present embodiment is formed by mixing the following components by weight percentage:

[0058]

[0059]

[0060] The emulsifier is preferably at least one of sodium stearate and sodium lauryl sulfate.

[0061] It should be pointed out that the cleaning agent of the present invention mainly utilizes the universal decontamination effect of surfactants to improve the cleaning effect. Therefore, each embodiment of the present invention can use any surfactant in the prior art. The applicant found through research that when the surfactant is at least one of alkylbenzenesulfonic acid, sodium lauryl ether sulfate, and coconut oil diethanolamine, a better cleaning effect can be achieved, which can be used as a preferred technical means.

[0062] The cleaning agent of this embodiment is a powder easily soluble in water.

[0063] The preparation method of the cleaning agent of the present embodiment comprises the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com