Method for increasing activity of microbial flocculant

A microbial flocculant and flocculant technology, applied in separation methods, chemical instruments and methods, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of unstable microbial flocculant production technology, high cost, secondary pollution, etc. Achieve the effect of simple operation, remarkable effect and broad application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 microbial flocculant

[0031] 1. Microbial flocculant fermentation method

[0032] Medium A was used for the activation and fermentation of Brevibacillus brevis CGMCC1.931, and Medium B was used for the activation and fermentation of Rhodococcus erythropolis CGMCC1.2362. After the strains were activated, they were transferred to (30mL / 300mL) Erlenmeyer flasks of corresponding fermentation medium according to the inoculated amount of 1% respectively, and then fermented with flocculants at 30°C, 120rpm, and fermented for 96h.

[0033] 2. Microbial flocculant preparation

[0034]Brevibacillus CGMCC1.931 polysaccharide flocculant preparation: fermentation broth 100mL, 10000×g, 4°C, centrifuged for 15min, and the supernatant was taken. The supernatant was concentrated in a vacuum concentrator to 1 / 4 of the original volume. Add 3 times the volume of absolute ethanol and let stand at -20°C overnight. Centrifuge at 10,000×g at 4°C for 15 minu...

Embodiment 2 4

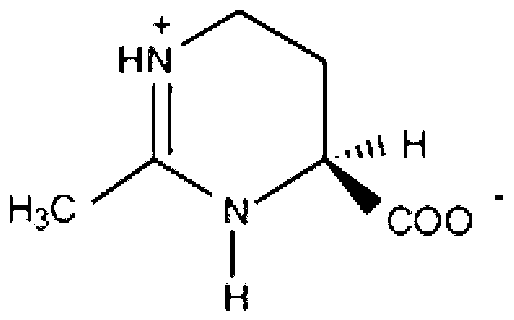

[0036] Example 2 The stress-resistance enhancement pretreatment of microbial flocculants by ectoine substances

[0037] 1. Flocculant sample preparation:

[0038] Sample a: 1 g of dry Bacillus brevis CGMCC1.931 flocculant powder prepared by the method described in Example 1 was dissolved in 10 mL of deionized water to prepare a concentration of 0.1 g / mL.

[0039] Samples b1-b3: flocculants treated with ectoine stress-enhancing treatment (sample a was prepared with 0.1, 1, and 10 g / L ectoine, and placed at room temperature for 30 minutes before use).

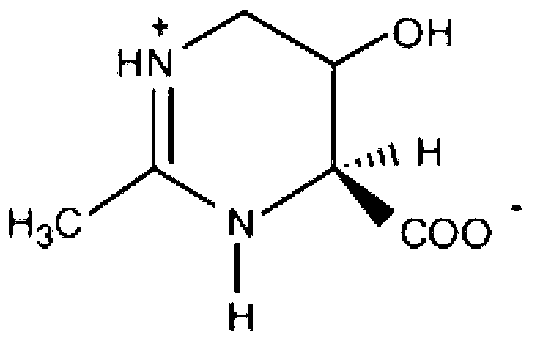

[0040] Samples c1~c3: flocculants treated with hydroxyectoine stress-enhancing treatment (sample a was prepared with 0.1, 1, 10 g / L hydroxyectoine, and used after standing at room temperature for 30 minutes). The flocculant sample preparation is shown in Table 1.

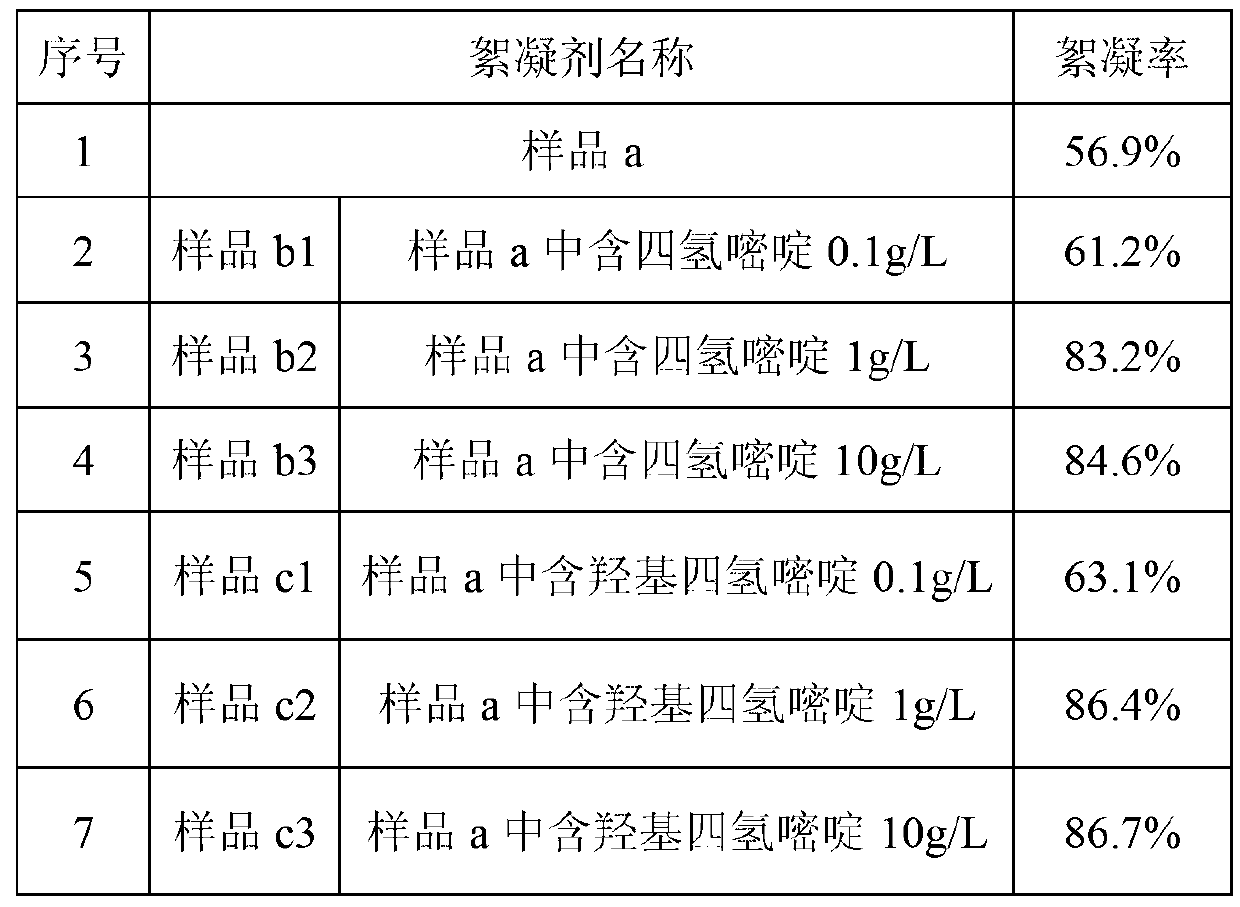

[0041] Table 1 Flocculant sample preparation

[0042]

[0043] 2. Determination method of flocculation rate:

[0044] Under the stirring state of 120rpm, add 0....

Embodiment 3

[0051] Example 3 ectoine improves the flocculation activity of microbial flocculants at high temperatures

[0052] Rhodococcus erythropolis CGMCC1.2362 produces protein flocculants [Wang Lan, Tang Jing, Zhao Xuan, Research methods for the flocculation mechanism of microbial flocculants, Journal of Environmental Engineering Vol.5, No.3, March 2011]. The structure of protein flocculants is unstable at high temperature, and the flocculation activity is significantly reduced. This example is used to prove that the use of ectoine can protect the flocculation activity of protein flocculants at high temperatures, and the specific methods are as follows:

[0053] Prepare 2 parts of kaolin suspension (0.5g of kaolin is added to 100mL of distilled water), one of which is added with 0.5mL of Rhodococcus erythropolis CGMCC1.2362 flocculant (the dry powder of Rhodococcus erythropolis CGMCC1.2362 flocculant prepared by the method described in Example 1 1g, dissolved in 10mL deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com