Industrial production method of high-purity N-lauroyl-L-alanine surfactant

A technology for surfactants and production methods, applied in chemical instruments and methods, separation/purification of carboxylic acid amides, organic chemistry, etc., can solve the problems of difficulty in realizing industrialized large-scale production, great influence on product quality, and low product purity, etc. The method is simple and practical, the appearance and color are good, and the content is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

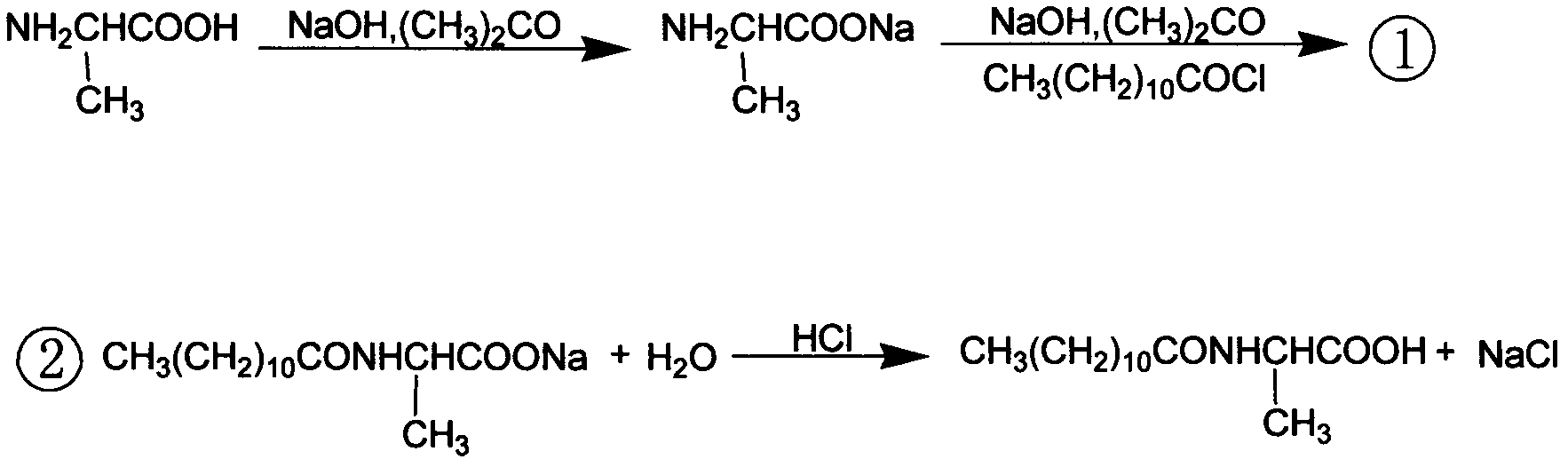

Method used

Image

Examples

Embodiment 1

[0027] At room temperature, in a 1000ml four-neck flask, dissolve 89g (1mol) L-alanine in 200mL water, add 40g (1mol) NaOH, then add 200mL acetone and stir well; control the temperature at 24-26°C, slowly and uniformly Add 198.6g (0.9mol) of lauroyl chloride dropwise, drop it for about 1 hour, then add about 72mL of 50% sodium hydroxide aqueous solution dropwise, carefully control the pH value of the reaction solution at about 9, after the dropwise addition, in 24-26 ℃ and then continue to keep the pH between about 9 and react for 2 hours until the pH remains unchanged. A white paste reactant is obtained. Stop the reaction and acidify it with 0.6mol / L hydrochloric acid to pH 3-4. Solids gradually precipitate out and place in an ice bath. After 2 hours, it was filtered, and the obtained solid was stirred and washed twice with water, and dried to obtain 234 g of crude N-lauroyl-L-alanine.

[0028] Get crude product 100g, be dissolved in the mixed solvent of 400mL, described mixe...

Embodiment 2

[0030] At room temperature, in a 1000mL four-neck flask, dissolve 89g (1mol) L-alanine in 200mL water, add 56g (1mol) KOH, then add 200mL acetone and stir well; control the temperature at 24-26°C, slowly and uniformly Add 198.6g (0.9mol) of lauroyl chloride dropwise, drop it for about 1 hour, then add about 100mL of 50% KOH aqueous solution dropwise, carefully control the pH value of the reaction solution at about 9, and continue at 24-26°C after the dropwise addition Keep the pH at about 9 and react for 2 hours until the pH remains unchanged. A white paste reactant is obtained. Stop the reaction and acidify it to pH 3-4 with 0.6mol / L hydrochloric acid. Solids gradually precipitate out and stand in an ice bath for 2 hours. , filtered, the obtained solid was stirred and washed twice with water, and dried to obtain 231.1 g of crude N-lauroyl-L-alanine.

[0031] Get crude product 100g, be dissolved in 400mL mixed solvent, described mixed solvent is made up of 100mL acetone, 100mL...

Embodiment 3

[0033] At room temperature, in a 1000mL four-neck flask, dissolve 89g (1mol) L-alanine in 200mL water, add 53g (0.5mol) Na2CO3, then add 200mL acetone and stir well; control the temperature at 24-26°C, slowly Add 198.6g (0.9mol) lauroyl chloride dropwise at a constant speed, and drop it in about 1 hour, then add about 95mL of 50% sodium carbonate aqueous solution dropwise, carefully control the pH value of the reaction solution at about 9, after the dropwise addition, at 24-26°C Continue to keep the pH between about 9 and react for 2 hours until the pH remains unchanged, and a white paste reactant is obtained. Stop the reaction and acidify it to pH 3-4 with 0.6mol / L hydrochloric acid. hours, filtered, and the obtained solid was stirred and washed twice with water, and dried to obtain 226 g of crude N-lauroyl-L-alanine.

[0034] Get crude product 100g, be dissolved in 400mL mixed solvent, described mixed solvent is made up of 100mL acetone, 100mL ethanol, 200mL water, heat and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com