Technological method of using alumina byproduct red mud for producing polyvinyl chloride (PVC) packing

A process method, aluminum oxide technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of alkali pollution in the ecological environment, achieve good flame retardancy, prolong service life, and good insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

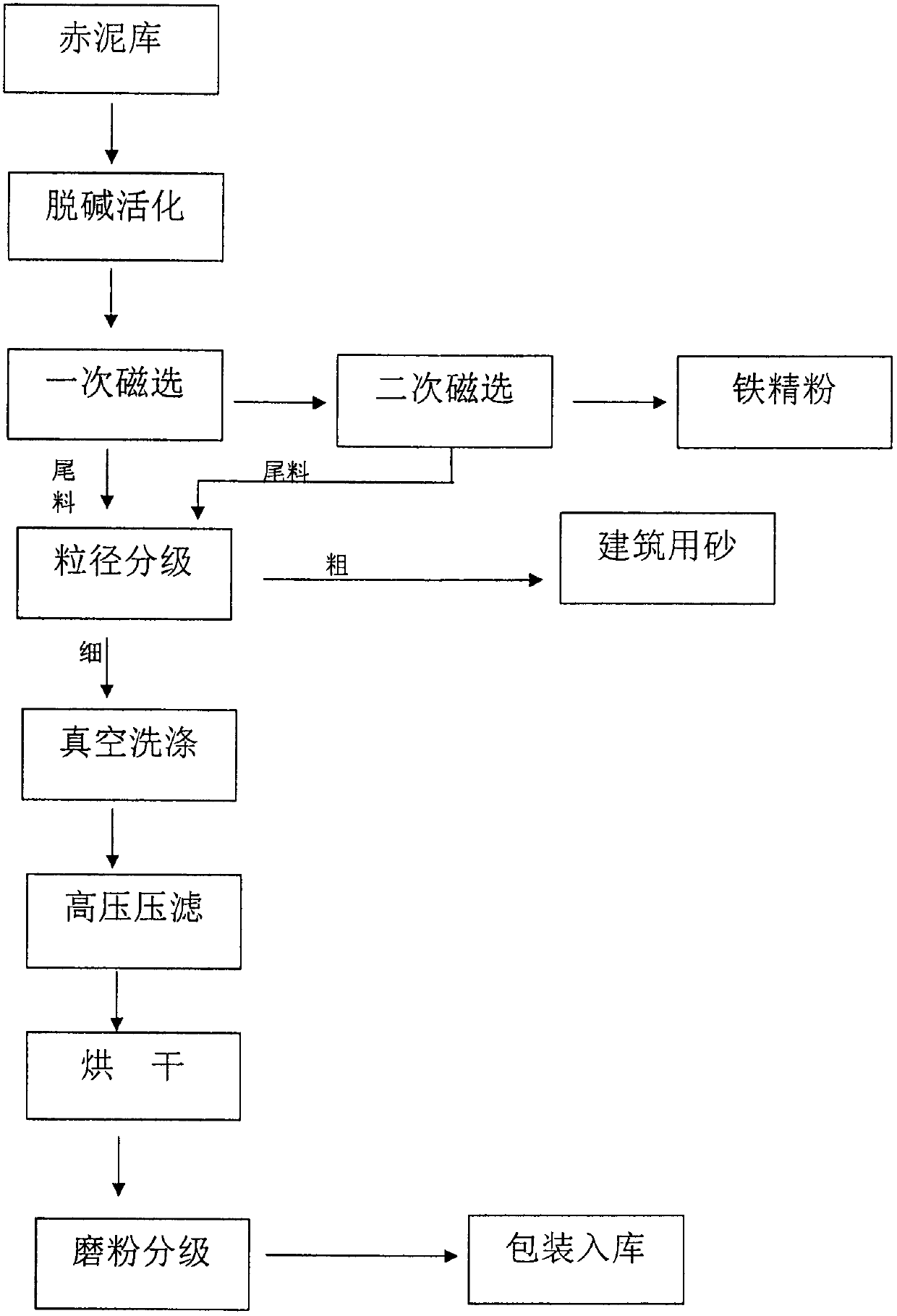

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] As shown in the figure, the process for producing PVC filler by using alumina by-product red mud mainly includes the following steps: first, dealkalization and activation section. Send the red mud slurry excavated and beaten by the alumina plant or the red mud bank into the dealkalization activation reaction tank, and then add the compound dealkalization agent for dealkalization activation treatment. The addition amount of the compound dealkalizer is 15-17% (Based on the solid content of the red mud), the Na2O in the red mud can be reduced to below 0.50% within 30 minutes after adding. Second, iron selection and sand extraction section. The red mud after dealkalization is sent to the iron selection and sand extraction section, and the iron selection is completed by the first and second high gradient magnetic separators. The separation of coarse and fine sand is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com