Manufacturing method of soy-protein-type water-based decorative paper printing ink

A technology of soybean protein and manufacturing method, which is applied in ink, household utensils, applications, etc., can solve the problems of poor environmental protection performance, and achieve the effects of low cost, excellent overprinting, and high color saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

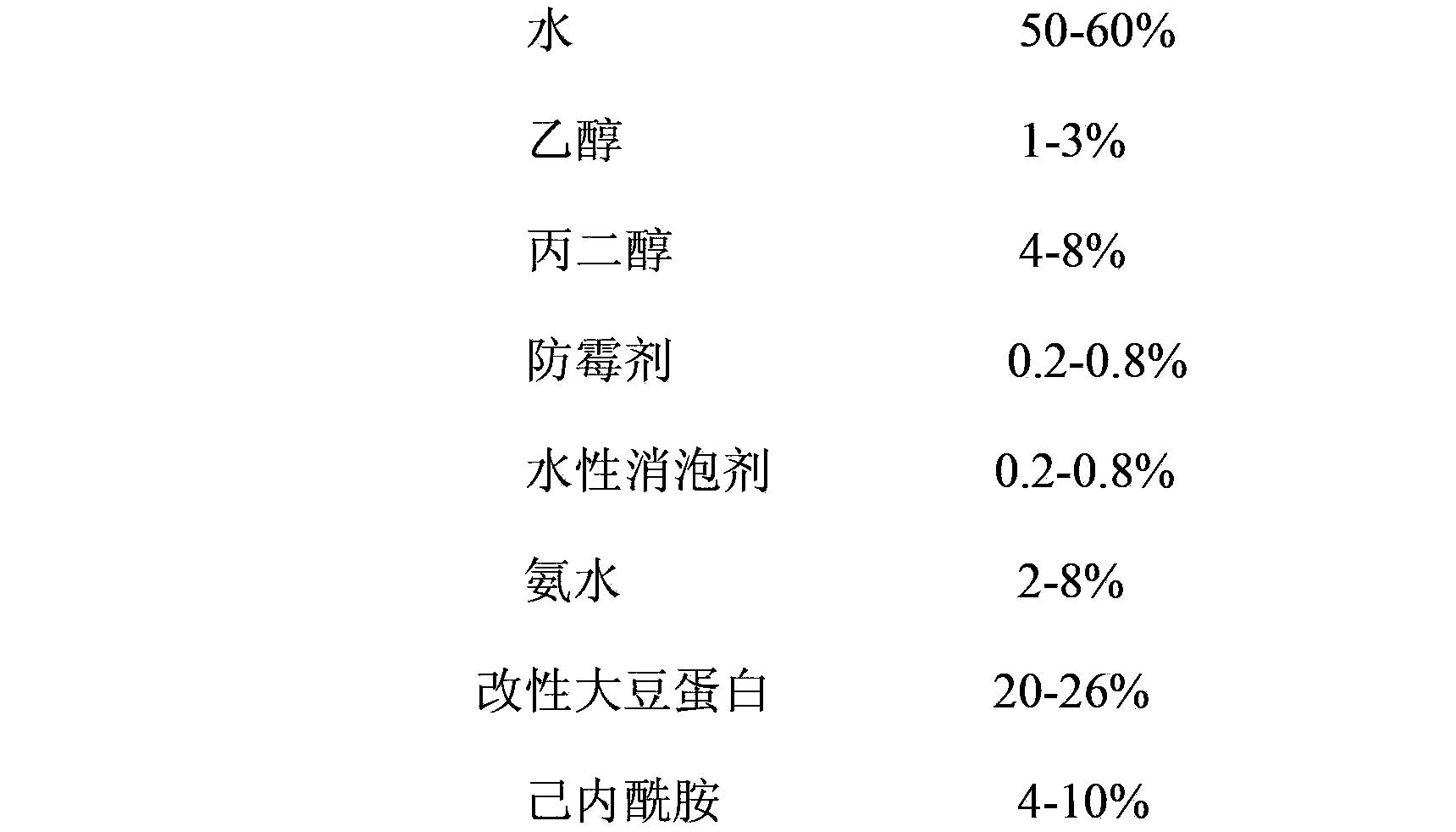

[0042]Step (1): Grind the resin solution, and weigh the raw materials with the following mass ratio:

[0043]

[0044] Step (2): Add water, ethanol, propylene glycol, antifungal agent, water-based defoamer and ammonia water in proportion to the mixing tank, stir evenly and add modified soybean protein and caprolactam, at 25°C at 800 rpm Stir in a high-speed mixer until completely dissolved, and the pH value is controlled between 8.0-8.5;

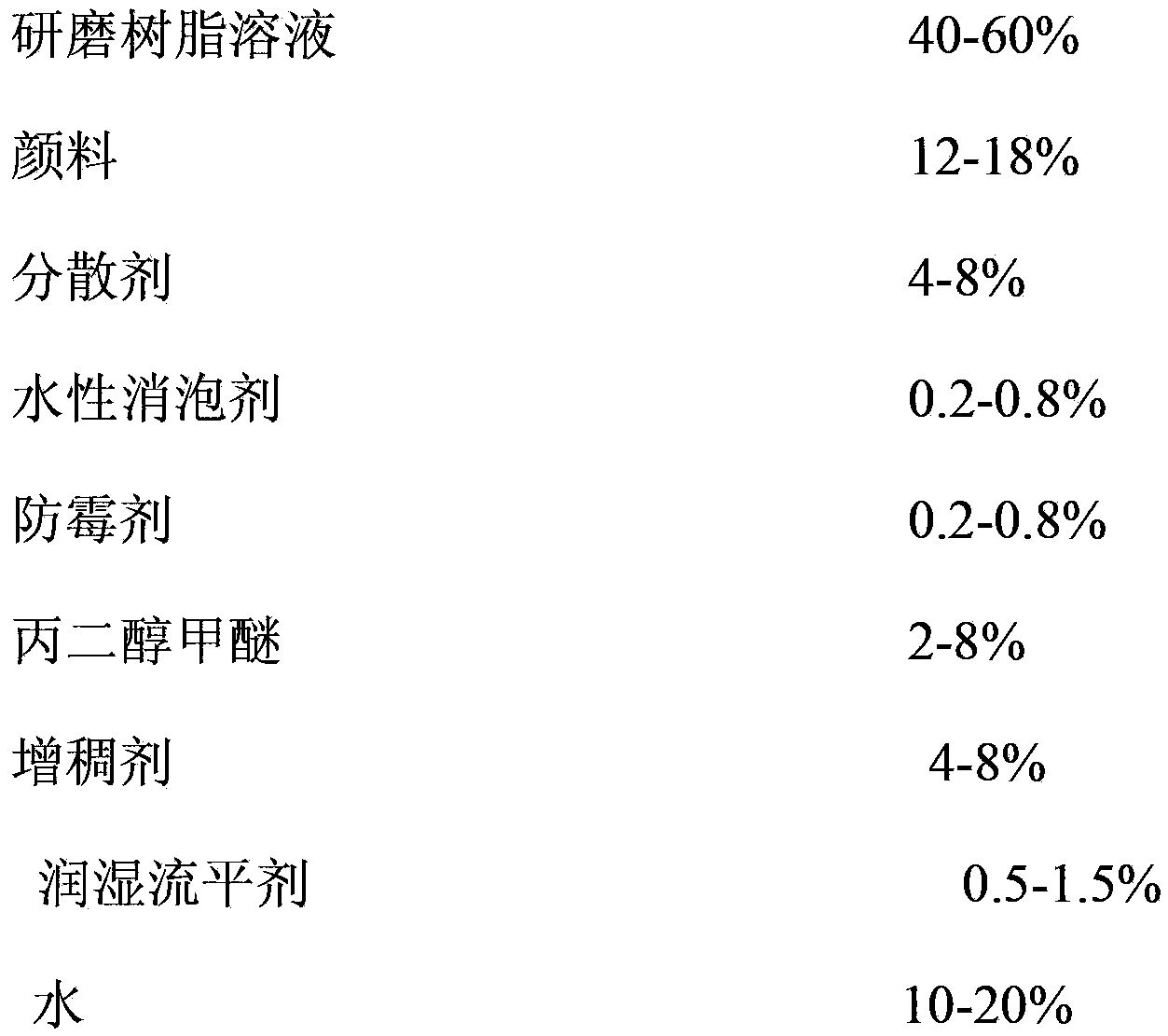

[0045] Step (3): Take the grinding resin solution obtained in the above step (2), add pigment, dispersant, water-based defoamer, antifungal agent, propylene glycol methyl ether, thickener, wetting and leveling agent and water, the amount of each raw material Weigh according to the following weight ratio:

[0046]

[0047]

[0048] The above raw materials are mixed in a high-speed mixer, stirred evenly at a speed of 500-800 rpm, and then put into a bead mill for grinding for 2 hours, the fineness is less than 5mm, and the water-base...

Embodiment 2

[0056] Step (1): Grind the resin solution, and weigh the raw materials with the following mass ratio:

[0057]

[0058] Step (2): Add water, ethanol, propylene glycol, antifungal agent, water-based defoamer and ammonia water in proportion to the mixing tank, stir evenly and add modified soybean protein and caprolactam, at 25°C at 800 rpm Stir in a high-speed mixer until completely dissolved, and the pH value is controlled between 8.0-8.5;

[0059] Step (3): Take the grinding resin solution obtained in the above step (2), add pigment, dispersant, water-based defoamer, antifungal agent, propylene glycol methyl ether, thickener, wetting and leveling agent and water, the amount of each raw material Weigh according to the following weight ratio:

[0060]

[0061]

[0062] The above raw materials are mixed in a high-speed mixer, stirred evenly at a speed of 500-800 rpm, and then put into a bead mill for grinding for 2 hours, the fineness is less than 5mm, and the water-bas...

Embodiment 3

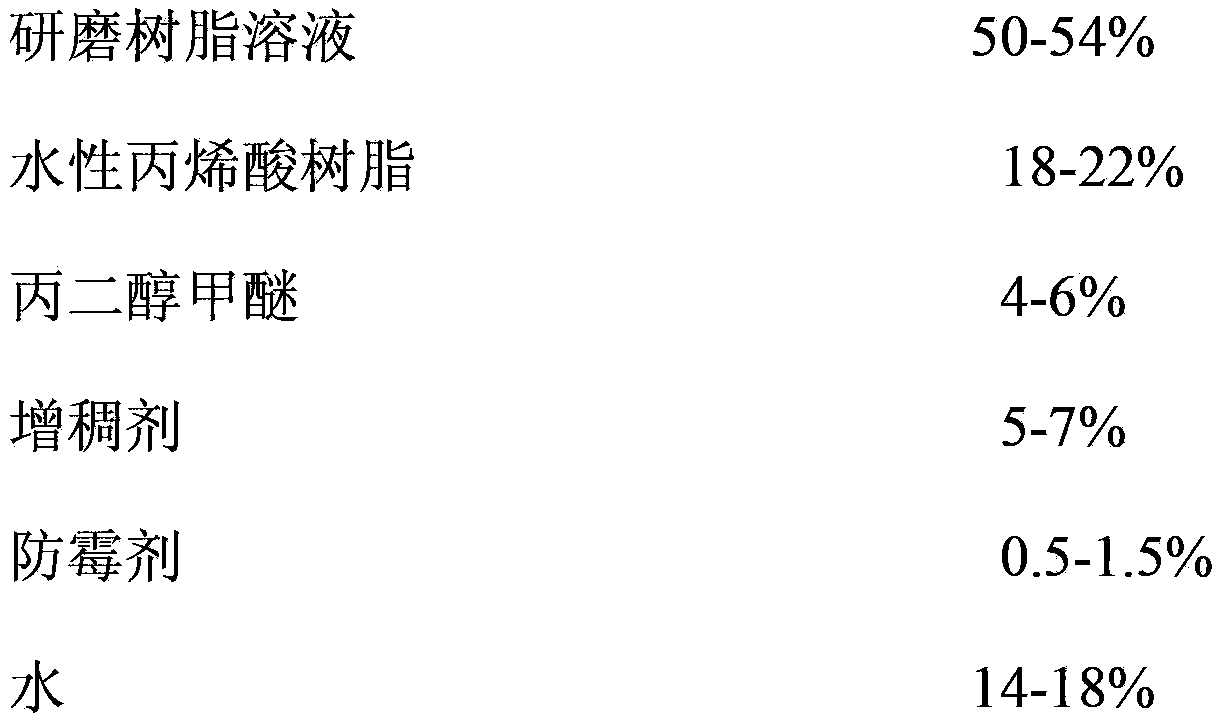

[0069] Step (1): Grind the resin solution, and weigh the raw materials with the following mass ratio:

[0070]

[0071] Step (2): Add water, ethanol, propylene glycol, antifungal agent, water-based defoamer and ammonia water in proportion to the mixing tank, stir evenly, add modified soybean protein and caprolactam, at 20°C to 25°C at 500-800 Stir in a high-speed mixer with rpm until completely dissolved, and the pH value is controlled between 8.0-8.5;

[0072] Step (3): Take the grinding resin solution obtained in the above step (2), add pigment, dispersant, water-based defoamer, antifungal agent, propylene glycol methyl ether, thickener, wetting and leveling agent and water, the amount of each raw material Weigh according to the following weight ratio:

[0073]

[0074]

[0075] The above raw materials are mixed in a high-speed mixer, stirred evenly at a speed of 500-800 rpm, and then put into a bead mill for grinding for 2 hours, the fineness is less than 5mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freshness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com