Method of improving concentration of butanol in process of acetone butanol fermentation

An acetone-butanol fermentation and concentration technology, applied in the direction of microorganism-based methods, fermentation, biochemical equipment and methods, can solve the problems of high energy consumption in the condensation process, low butanol content, high separation costs, etc., to reduce distillation Energy consumption, increased final product concentration, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 micellar toxicity test

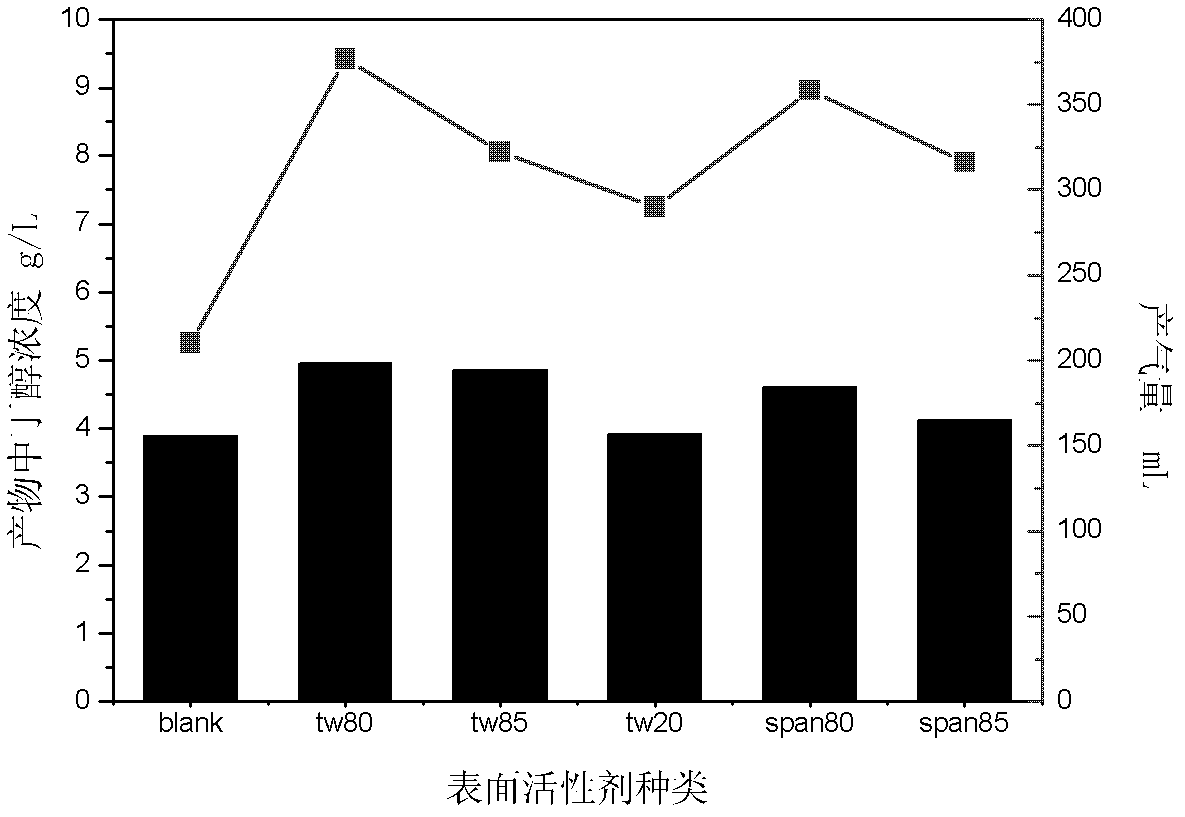

[0030]The seed solution (Clostridium beijerinckiiY3) of the ABE (acetone, butanol, ethanol) fermentation process was anaerobically cultured at 37 degrees for 12 hours, and was inoculated into 30mL medium (see Table 1 for the medium composition) according to the 10% inoculum size of the seed solution. , different types of surfactants were added to the culture medium, including Tween 20, Tween 80, Tween 85, Span 80, Span 85, the addition amount was 2wt%, and cultured in a shaker at 150rpm / min for 12 hours, Utilize drainage method to measure the gas production in each shake flask, after fermentation carries out 24 hours, measure butanol concentration in each shake flask, do blank control simultaneously (referring to figure 2 ). Depend on figure 2 It can be seen from the figure that after 24 hours of fermentation under this culture condition, the concentration of butanol did not reach the inhibitory concentration, so the gas product...

Embodiment 2

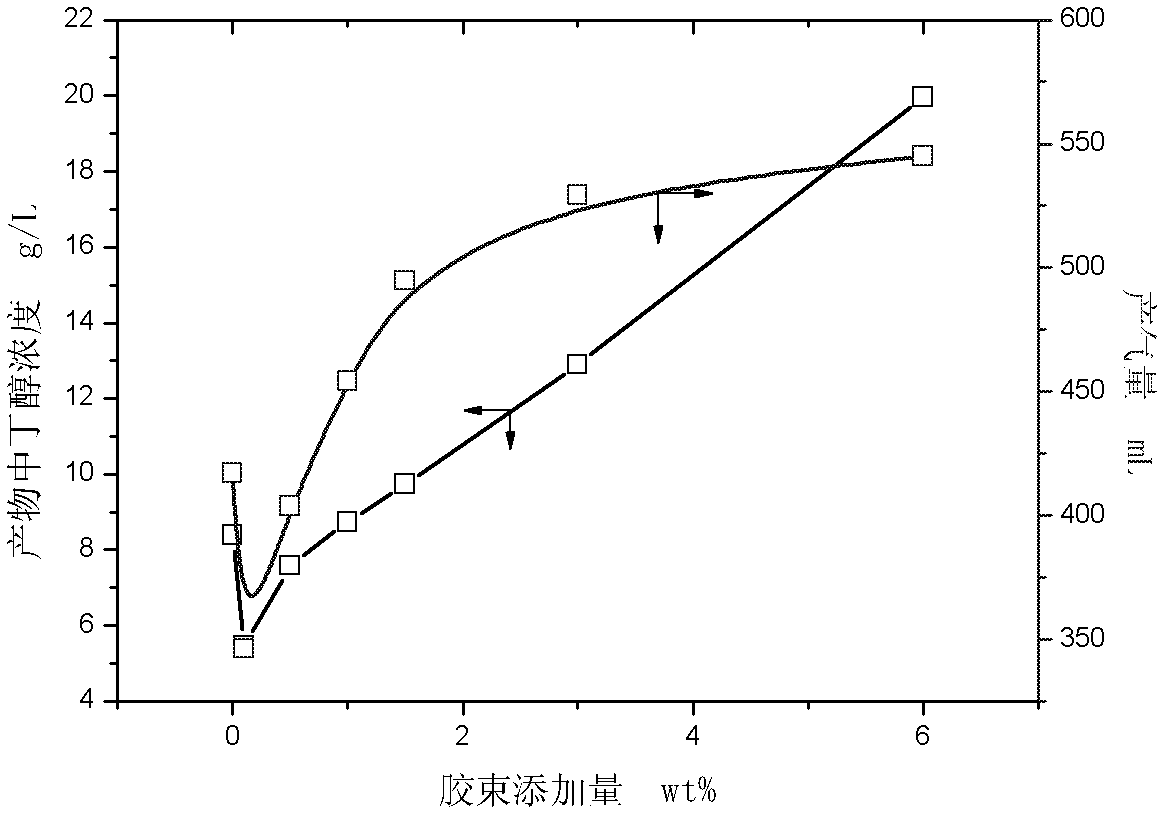

[0034] Taking Tween 80 as an example, the effect of concentration is similar to that of micellar toxicity experiment. Tested by shake flask batch fermentation. The seed solution (Clostridium beijerinckii Y3) was anaerobically cultured at 37 degrees for 12 hours, and was inoculated into 10 mL of medium (see Table 1 for medium composition) according to 10% inoculum size, and different concentrations of Tween 80 were added to the medium. From 0-6%, cultivated in 150rpm / min shaker for 12 hours, utilized the drainage method to measure the gas production in each shake flask, after fermentation carried out 72 hours, measured the butanol concentration in each shake flask, and blank control was done simultaneously (see image 3 ). image 3 It can be seen that with the increase of surfactant addition, the gas production and butanol concentration of the product both increase. This indicated that surfactants could effectively solubilize butanol in the product, thereby weakening the inhi...

Embodiment 3

[0036] Configure a series of butanol aqueous solutions without surfactant, and use the headspace gas phase to measure the proportional relationship between the butanol concentration in the solution and the butanol chromatographic area in the gas above, as a standard curve (see Figure 4 ). Configure a series of butanol aqueous solution containing surfactant and known butanol concentration, according to the above-mentioned standard curve, compare the concentration contrast containing surfactant and not containing active agent (see Figure 5 ). Depend on Figure 4 It can be seen that the linear correlation between butanol concentration and chromatographic area in the standard curve is very high, indicating that the concentration of butanol solution can be converted by the gas concentration above the solution. Depend on Figure 5 It can be seen that for samples with different concentrations of butanol, the concentration change decreases with the increase of surfactant addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com