Calcitriol emulsion and preparation method thereof

A technology of calcitriol emulsion and emulsifier, which is applied in bone diseases, pharmaceutical formulations, emulsion delivery, etc. It can solve problems such as monotonous dosage forms, low content of active ingredients, poor stability of soft capsules and capsules, etc. To achieve the effect of increasing bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

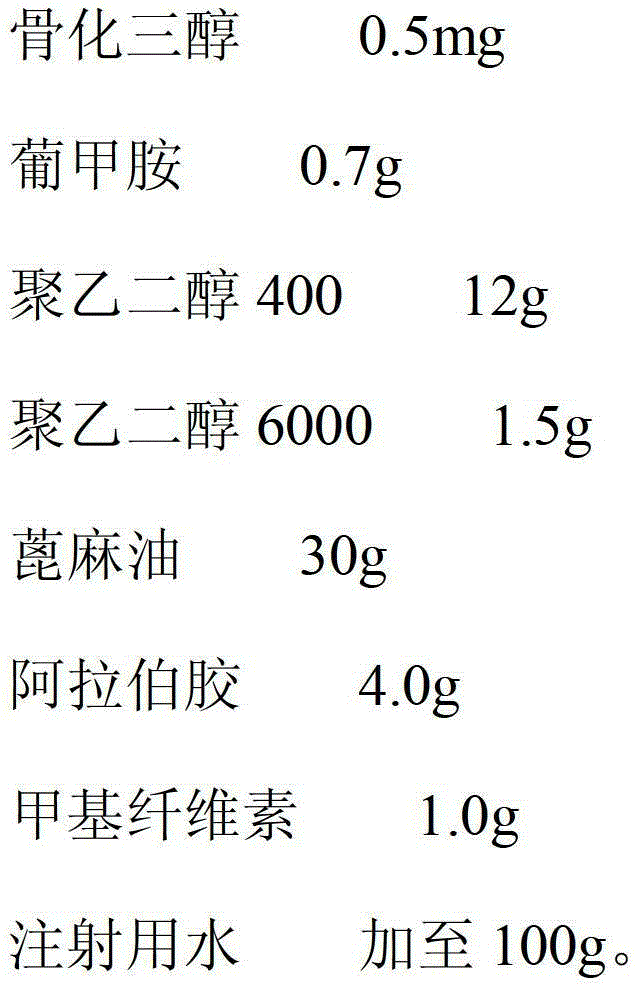

[0024] Embodiment 1 calcitriol emulsion

[0025] The prescription is:

[0026]

[0027] The preparation method is:

[0028] 1) Take the prescribed amount of castor oil, add the prescribed amount of calcitriol, gum arabic and methylcellulose, and stir evenly at 500rpm to obtain the oil phase;

[0029] 2) Take the prescribed amount of water for injection, add the prescribed amount of polyethylene glycol 400, and stir evenly; continue to add the prescribed amount of meglumine and polyethylene glycol 6000, and stir at 45°C for 15 minutes until completely dissolved to obtain a solution;

[0030] 3) Slowly add the above oil phase into the obtained solution along the same direction at a stirring speed of 500 rpm, emulsify twice in a high-pressure homogenizer, filter and fill, and sterilize at 115°C for 30 minutes to obtain the product.

Embodiment 2

[0031] Embodiment 2 calcitriol emulsion

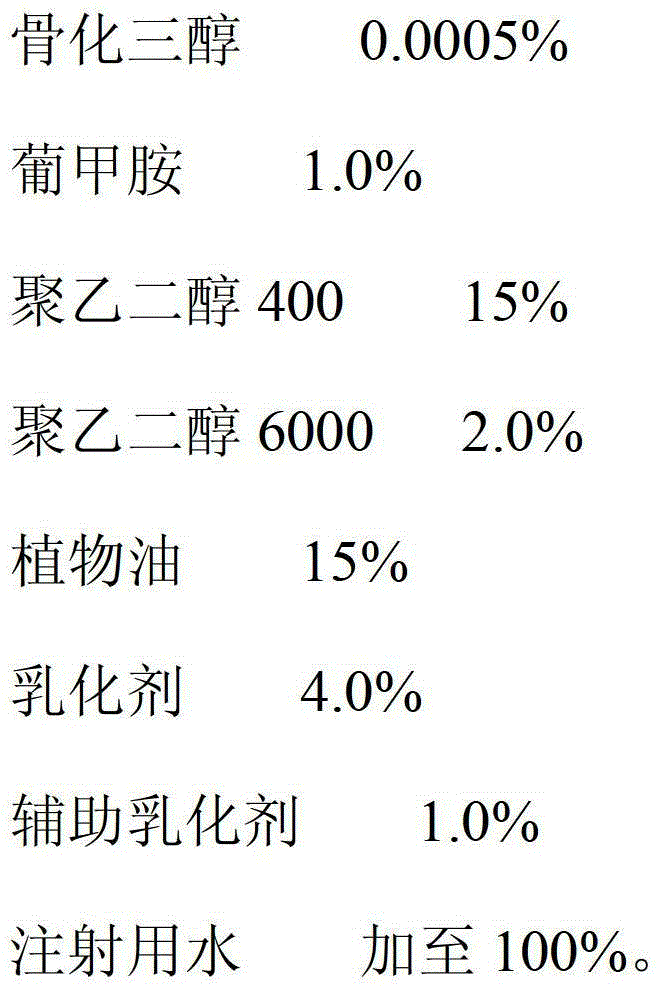

[0032] The prescription is:

[0033]

[0034] The preparation method is:

[0035] 1) Take the prescribed amount of peanut oil, add the prescribed amount of calcitriol, tragacanth gum and hydroxypropyl cellulose, and stir evenly at 1000 rpm to obtain the oil phase;

[0036] 2) Take the prescribed amount of water for injection, add the prescribed amount of polyethylene glycol 400, and stir evenly; continue to add the prescribed amount of meglumine and polyethylene glycol 6000, and stir at 55°C for 25 minutes until completely dissolved to obtain a solution;

[0037] 3) Slowly add the above oil phase into the obtained solution along the same direction at a stirring speed of 1000 rpm, emulsify 4 times in a high-pressure homogenizer, filter and fill, and sterilize at 115°C for 30 minutes to obtain the product.

Embodiment 3

[0038] Embodiment 3 calcitriol emulsion

[0039] The prescription is:

[0040]

[0041]

[0042] The preparation method is:

[0043] 1) Take the prescribed amount of corn oil, add the prescribed amount of calcitriol, poloxamer and sodium alginate, and stir evenly at 800 rpm to obtain the oil phase;

[0044] 2) Take the prescribed amount of water for injection, add the prescribed amount of polyethylene glycol 400, and stir evenly; continue to add the prescribed amount of meglumine and polyethylene glycol 6000, and stir at 50°C for 20 minutes until completely dissolved to obtain a solution;

[0045] 3) Slowly add the above oil phase into the obtained solution along the same direction at a stirring speed of 800 rpm, emulsify in a high-pressure homogenizer for 3 times, filter and fill, and sterilize at 115°C for 30 minutes to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com