Preparation method of high-efficiency hydrophobic medium and application of high-efficiency hydrophobic medium in purification of defibrase

A technology of hydrophobic medium and defibrase, which is applied in the field of biochemistry and achieves the effects of high yield, simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

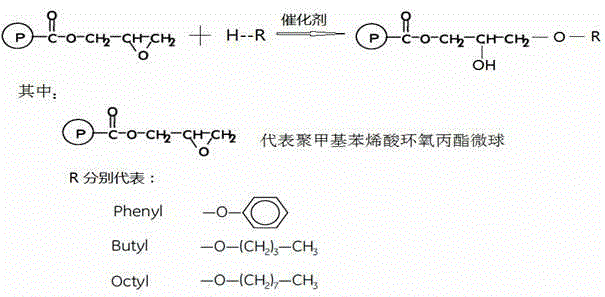

Method used

Image

Examples

Embodiment 1

[0022] 1) Weigh 1g of BPO, 5g of PVP, 50g of GMA, 600ml of ethanol, and 70ml of toluene. Add the weighed raw materials into an appropriate glass reaction bottle, make it fully dissolved and blow nitrogen to remove oxygen. Then place the reaction bottle on a device with a rotating and heating device, and polymerize at 75 degrees Celsius for 24 hours. After the reaction, the solvent was removed by sedimentation, washed with ethanol, and dried in vacuum for 24 hours to obtain monodisperse PGMA microspheres.

[0023] 2) Put 50g of PGMA microspheres obtained in the first step into a 250ml glass reactor (with a water bath), add 50ml of dioxane, adjust the temperature of the water bath to 50°C, and add 0.5 ml, stirred for 5 minutes, then added 5ml of n-butanol and continued to stir, the reaction time was 30 minutes, collected microspheres, washed with purified water and dioxane alternately three times each, and finally washed twice with dioxane; dried to obtain butanol Base polymer...

Embodiment 2

[0026] 1) Weigh 15g of BPO, 100g of PVP, 750g of GMA, 7000ml of ethanol, and 1200ml of toluene. Add the weighed raw materials into a 20L glass reaction bottle, make it fully dissolved and blow nitrogen to remove oxygen. Then place the reaction bottle on a device with a rotating and heating device, and polymerize at 70 degrees Celsius for 30 hours. After the reaction, the solvent was removed by sedimentation, washed with ethanol, and dried in vacuum for 24 hours to obtain monodisperse PGMA microspheres.

[0027] 2) Put 375g of PGMA microspheres obtained in the first step into a 1000ml glass reactor (with a water bath), add 375ml of dioxane, adjust the temperature of the water bath to 45°C, add in the catalyst (boron trifluoride ether) 3.75 ml, after stirring for 5 minutes, add 40ml of n-octanol and continue stirring, the reaction time is 40min, collect microspheres, wash with purified water and dioxane alternately three times each, and finally wash twice with dioxane; dry to o...

Embodiment 3

[0030]1) Weigh 15g of AIBN, 120g of PVP, 650g of GMA, 6500ml of ethanol, and 1000ml of toluene. Add the weighed raw materials into a 20L glass reaction bottle, make it fully dissolved and blow nitrogen to remove oxygen. Then place the reaction bottle on a device with a rotating and heating device, and polymerize at 75 degrees Celsius for 36 hours. After the reaction, the solvent was removed by sedimentation, washed with ethanol, and dried in vacuum for 24 hours to obtain monodisperse PGMA microspheres.

[0031] 2) Weigh 375g of PGMA microspheres obtained in the first step, put them in a 1000ml glass reactor (with a water bath), add 375ml of dioxane, adjust the temperature of the water bath to 50°C, and add in the catalyst (boron trifluoride ether) 4ml, stirred for 5min, added 40ml of liquid phenol and continued to stir, the reaction time was 50min, collected microspheres, washed with purified water and dioxane alternately three times each, and finally washed twice with dioxan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com