Method and device for extracting ricinus communis oil by using aqueous enzymatic method

A technology of castor oil and water enzymatic method, which is applied in the direction of fat oil/fat production and fat production, to achieve the effects of mild operating conditions, lower costs and higher oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

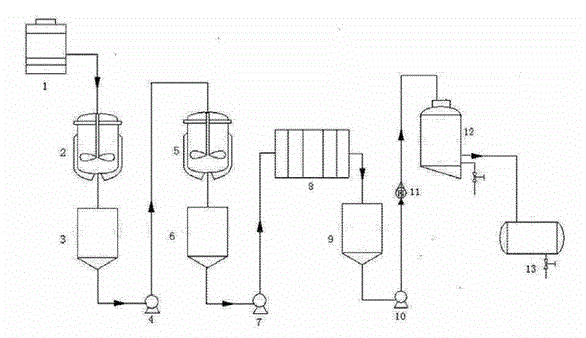

[0029] Referring to the accompanying drawings, this embodiment is an embodiment of the device for implementing the method for extracting castor oil by aqueous enzymatic method, including a roller mill 1, a soaking tank 2, an intermediate storage tank I3, a gear pump I4, an enzyme reactor 5, and an intermediate storage tank Ⅱ6, reciprocating pump Ⅱ7, filter press 8, intermediate storage tank Ⅲ9, centrifugal pump Ⅲ10, rotameter 11, centrifuge 12, product storage tank 13; The outlet is connected to the inlet of the intermediate storage tank I3, the outlet of the intermediate storage tank I3 is connected to the upper inlet of the enzyme reactor 5 through a pipeline with a gear pump I4, the bottom outlet of the enzyme reactor 5 is connected to the inlet of the intermediate storage tank II6, and the outlet of the intermediate storage tank II6 The pipeline with reciprocating pump Ⅱ7 is connected to the inlet of filter press 8, the outlet of filter press 8 is connected to the inlet of ...

Embodiment 2

[0033] The present embodiment adopts the device of embodiment 1 to extract castor oil, specifically comprises the following steps:

[0034] (1) Grinding and soaking: Put the castor kernels that have been shelled and peeled off the seed coat into the pulverizer 1 for pulverization (dry pulverization), and then send them into the soaking tank 2. Add phosphate buffer solution at a ratio of 1:4g / ml, turn on the agitator and jacket heating or cooling device inside the soaking tank 2, maintain the temperature in the tank at 30°C, soak for 4 hours, and send the soaked material to the intermediate storage tank I3;

[0035] (2) Enzyme reaction: use the feed pump I4 to send the material soaked in step (1) from the intermediate storage tank I3 to the enzyme reactor 5, adjust the pH value of the soaked slurry to 6.5 with hydrochloric acid solution, and add equivalent The raw material is neutral protease with 3% mass of castor kernels, the stirrer and heating or cooling device...

Embodiment 3

[0039] The present embodiment adopts the device of embodiment 1 to extract castor oil, specifically comprises the following steps:

[0040] (1) Grinding and soaking: Add the castor kernels of shelled and peeled seed coats into pulverizer 1 for pulverization (dry pulverization), and then send them into the soaking tank 2, according to the mass-volume ratio of castor kernels and phosphate buffer solution. Add phosphate buffer at a ratio of 1:3g / ml, turn on the agitator and jacket heating or cooling device inside the soaking tank 2, maintain the temperature in the tank at 35°C, soak for 2 hours, and send the soaked material to intermediate storage tank Ⅰ3 ;

[0041] (2) Enzyme reaction: use the feed pump I4 to send the material soaked in step (1) from the intermediate storage tank I3 to the enzyme reactor 5, adjust the pH of the soaked slurry to 8 with sodium hydroxide solution, add Use neutral protease with 2% mass of castor kernels as the raw material, turn on the stirrer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com