Temperature-regulating intelligent tent fabric and preparation method thereof

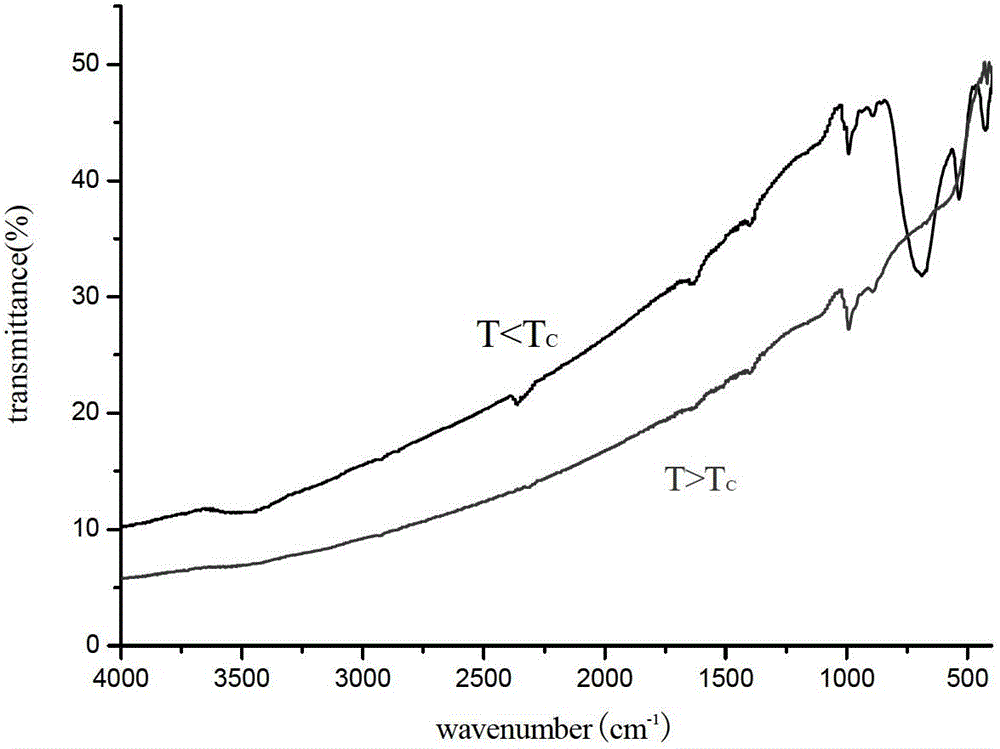

A temperature-controlled, intelligent technology, applied in fiber types, textiles and papermaking, fiber processing, etc., can solve problems such as user discomfort, and achieve the effect of improving comfort, improving internal temperature, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

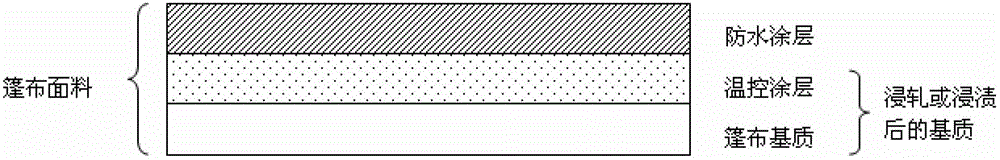

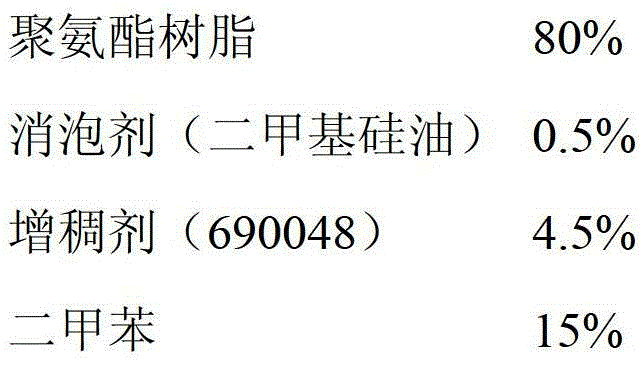

Method used

Image

Examples

Embodiment 1

[0031] At room temperature, use deionized water to prepare 150mL1mol / L vanadium oxide solution, 10mL1mol / L sodium tungstate solution, and 100mL2mol / L ammonium bicarbonate solution, first mix the sodium tungstate solution and vanadyl sulfate solution In a three-necked flask, stir for 5-10min at a stirring rate of 350-400rpm, then use a constant-flow pump to drip the ammonium bicarbonate solution into the above mixed solution within 60min, and continue stirring for 1-2h after the addition is complete, and the obtained precipitate passes through 220nm microporous membrane filter under reduced pressure, wash with deionized water until no SO 4 2- , washed with absolute ethanol, and vacuum-dried at 45°C to obtain a yellow-brown powder. The powder is calcined at a high temperature of 700-800° C. for 3 hours in an atmosphere furnace under a nitrogen atmosphere, and then continuously calcined at a nitrogen atmosphere of 500-600° C. for 2-3 hours to obtain a phase change material.

Embodiment 2

[0033]At room temperature, use deionized water to prepare 100mL of 0.05mol / L vanadium oxide solution, 5mL of 1mol / L ammonium tungstate solution, and 150mL of 0.1mol / L sodium bicarbonate solution. The solution is mixed and placed in a three-necked flask, stirred at a stirring rate of 270-300rpm for 20min, then using a constant flow pump to drop the sodium bicarbonate solution into the above mixed solution within 100-120min, and continue stirring for 3-5h after the addition is complete , the resulting precipitate was filtered with a 4# sand core funnel under reduced pressure, washed with deionized water until no SO 4 2- , Wash with absolute ethanol for 1-2 times, and dry under vacuum at 60°C. The obtained powder is calcined at a high temperature of 600-700° C. for 9 hours under an argon atmosphere in an atmosphere furnace, and then continuously calcined at 400-500° C. for 1 hour under an argon atmosphere to obtain a phase change material.

Embodiment 3

[0035] At room temperature, use deionized water to prepare 200mL0.5mol / L vanadium oxide solution, 10mL0.5mol / L sodium tungstate solution, 10mL0.5mol / L ammonium molybdate solution, and 150mL0.5mol / L sodium carbonate solution Solution, firstly mix sodium tungstate solution, ammonium molybdate solution and vanadyl sulfate solution and place them in a three-necked flask, stir for 25-30min at a stirring rate of 200-250rpm, and then use a constant flow pump to pump carbonic acid within 70-90min Add the sodium solution dropwise into the above mixed solution, and continue to stir for 8-10 hours after the dropwise addition, and the obtained precipitate is filtered through a 220nm microporous membrane under reduced pressure and washed with deionized water until there is no SO 4 2- , washed with acetone, vacuum dried at 30°C, then calcined at 900-1000°C for 2 hours under a nitrogen atmosphere, and then continued to be calcined at 700-800°C for 5-8 hours under a nitrogen atmosphere to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com