Non-asphaltic high polymer self-adhesive waterstop strip and preparation technology thereof

A polymer and non-asphalt technology, applied in non-polymer adhesive additives, water conservancy projects, belts, etc., can solve problems such as groundwater pollution, prolong service life, reduce the risk of pollution and damage to groundwater resources, and improve long-term The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

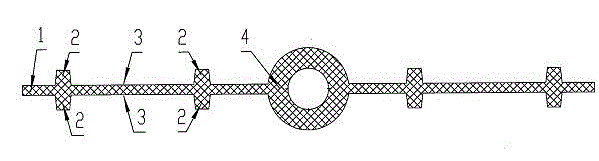

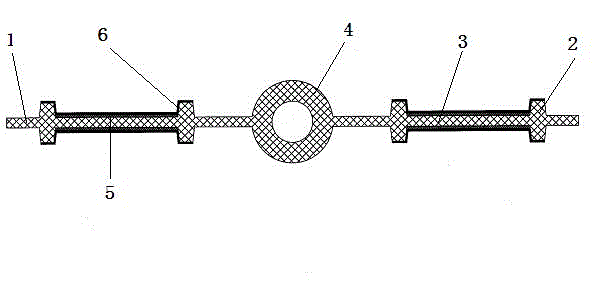

Image

Examples

Embodiment 1

[0029] The steps for preparing a non-asphalt polymer self-adhesive waterstop are as follows:

[0030] The first step is to prepare non-bituminous polymer self-adhesive adhesive

[0031] First, pour 8 parts by weight of plasticizer naphthenic oil into the reaction kettle, start the agitator, and heat to 170°C; Pour resin, 2 parts by weight of light absorbing agent titanium dioxide and 1 part by weight of filler calcium carbonate into the reactor, keep the temperature in the reactor at 170°C for 55 minutes; finally turn off the agitator and pour the self-adhesive liquid into the mold In the middle, after the self-adhesive liquid cools to room temperature and solidifies, cut the self-adhesive into pieces and wrap it with release paper;

[0032] The second step is to form non-asphalt polymer self-adhesive adhesive and waterstop base material

[0033] First, preheat the base material of the waterstop in an environment of 90°C for 3 minutes; then remove the release paper and heat ...

Embodiment 2

[0035] The steps for preparing a non-asphalt polymer self-adhesive waterstop are as follows:

[0036] The first step is to prepare non-bituminous polymer self-adhesive adhesive

[0037] First, pour 10 parts by weight of plasticizer naphthenic oil into the reaction kettle, start the stirrer, and heat to 180°C; then add 50 parts by weight of tackifier small molecular weight polyisobutylene, 25 parts by weight of SBS resin, Pour resin, 3 parts by weight of light absorbing agent titanium dioxide and 2 parts by weight of filler calcium carbonate into the reactor, keep the temperature in the reactor at 180°C for 60 minutes; finally turn off the agitator, pour the self-adhesive liquid into the mold, After the self-adhesive liquid cools to room temperature and solidifies, cut the self-adhesive into pieces and wrap it with release paper;

[0038] The second step is to form non-asphalt polymer self-adhesive adhesive and waterstop base material

[0039] First, preheat the base material...

Embodiment 3

[0041] The steps for preparing a non-asphalt polymer self-adhesive waterstop are as follows:

[0042] The first step is to prepare non-bituminous polymer self-adhesive adhesive

[0043]First, pour 12 parts by weight of plasticizer naphthenic oil into the reaction kettle, start the agitator, and heat to 190°C; then add 55 parts by weight of tackifier small molecular weight polyisobutylene, 28 parts by weight of SBS resin, Pour resin, 4 parts by weight of light absorbing agent titanium dioxide and 3 parts by weight of filler calcium carbonate into the reactor, keep the temperature in the reactor at 190°C for 65 minutes; finally turn off the agitator, pour the self-adhesive liquid into the mold, After the self-adhesive liquid cools to room temperature and solidifies, cut the self-adhesive into pieces and wrap it with release paper;

[0044] The second step is to form non-asphalt polymer self-adhesive adhesive and waterstop base material

[0045] First, preheat the base material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com