Heat-insulating wall

A technology for thermal insulation of walls and walls, applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of impossible building thermal insulation main body, high price of thermal insulation materials, high price of foam aluminum, etc., and achieve light bulk density, good fire and heat insulation , Improve the effect of fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

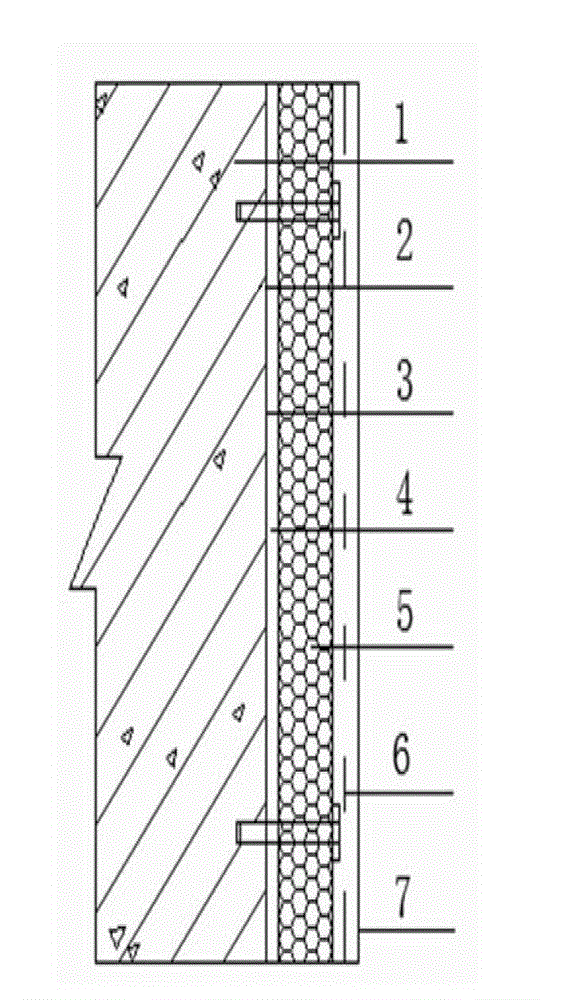

[0036] Embodiment 1, thermal insulation concrete wall

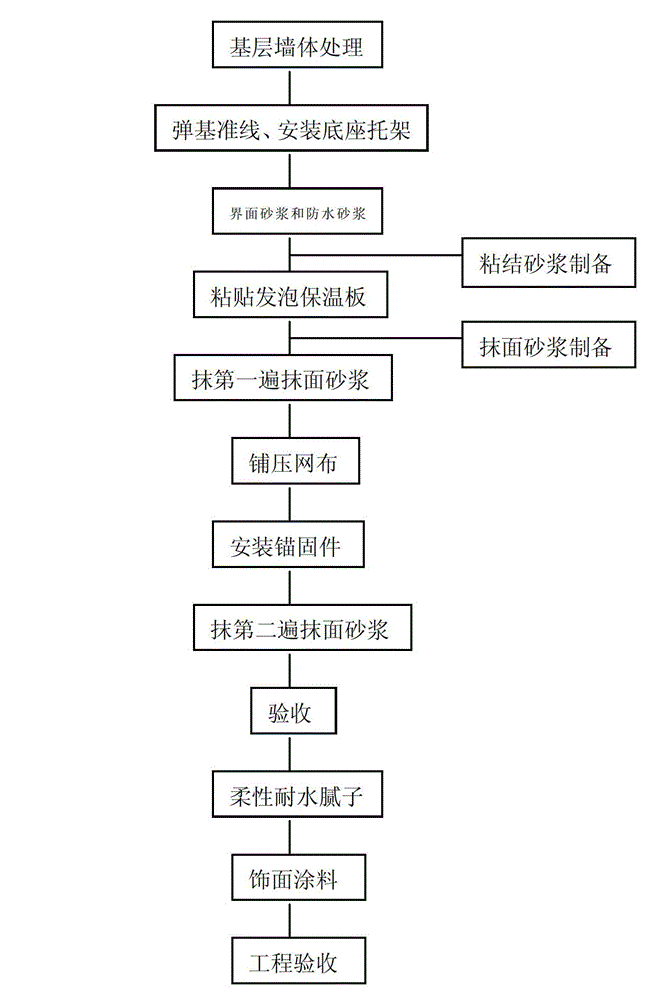

[0037] according to figure 1 The process flow shown is used to prepare the thermal insulation wall (for a certain house in a certain community). First, the concrete layer 1 of the base wall is processed, and the reference line is hung. Hang a vertical reference line at each floor, and hang a horizontal line at an appropriate position on each floor to control the verticality and levelness of the foamed cement board. Then, interface mortar and waterproof mortar are painted sequentially on the treated concrete layer 1 to obtain an interface layer 2 and a leveling layer 3 respectively. Then paint the bonding mortar on the leveling layer 3 to obtain the bonding layer 4 . Continue to paste the foam insulation board on the adhesive layer 4 as the insulation layer 5. When the foam insulation board is pasted on the adhesive layer 4, the full paste method should be used, and the following requirements should be met:

[0038] (1)...

Embodiment 2

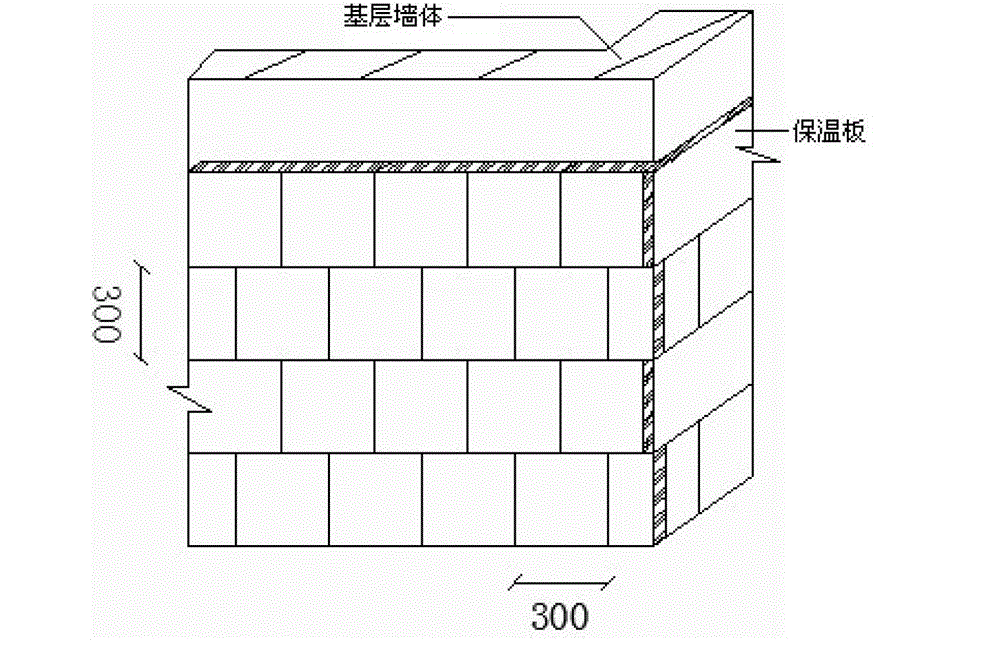

[0081] Embodiment 2, thermal insulation masonry wall

[0082] Prepare the thermal insulation wall (for a certain house in a certain community) according to the method and steps basically the same as in Example 1. First, process the base wall masonry, hang the reference line, and place it on each corner of the outer wall (yang corner, Inner corners) and other necessary places to hang vertical reference lines, and hang horizontal lines at appropriate positions on each floor to control the verticality and levelness of the foamed cement board. Then apply waterproof mortar on the treated masonry to obtain a leveling layer. Then paint the bonding mortar on the leveling layer to obtain the bonding layer. Continue to paste the foam insulation board on the adhesive layer as the insulation layer. When the foam insulation board is pasted on the adhesive layer, the full paste method should be used, and the following requirements should be met:

[0083] (1) The floating dust on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com