Organic thin film transistor, preparation method and preparation device thereof

A technology of organic thin film and preparation device, which is applied in the direction of surface coating liquid device, semiconductor/solid-state device manufacturing, electric solid-state device, etc. It can solve the problems of uniformity difference, waste of raw materials, and difficulty in applying flexible substrates, etc. Achieve the effect of improving yield and good performance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of the organic thin film transistor of the present invention comprises:

[0059] Forming a gate electrode, a gate insulating layer, an organic semiconductor layer and source and drain electrodes on the substrate;

[0060] Wherein, the step of forming the organic semiconductor layer comprises:

[0061] The solution in which the organic semiconductor material used to form the organic semiconductor layer is dissolved is blade-coated to form the organic semiconductor layer.

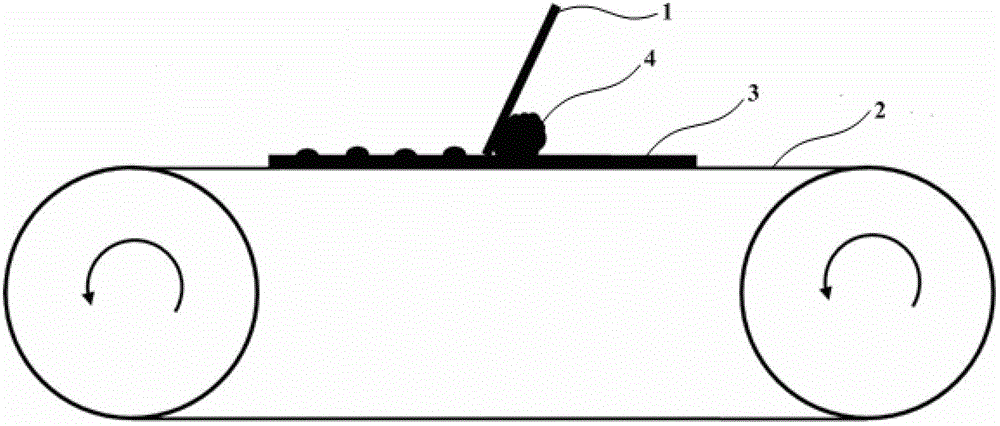

[0062] In the technical solution of the present invention, the prepared solution is scraped and coated on the substrate through a scraping process, and the scraper can be scraped on the substrate by moving along a straight line, or by rotating the scraper on the substrate. , during the entire scraping process, the scraper makes the transverse shear force of the solution on the substrate consistent, the thickness of the solution is consistent, and the state of each device is equa...

Embodiment 1

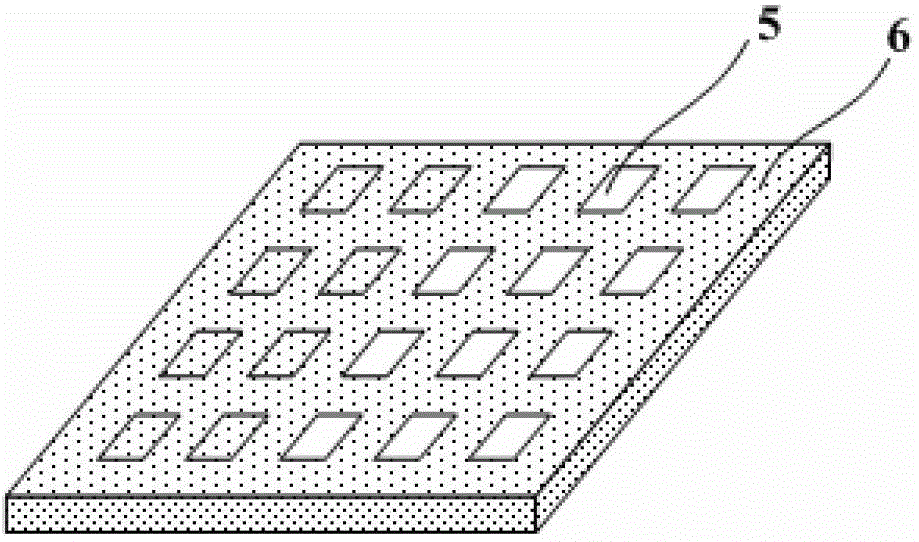

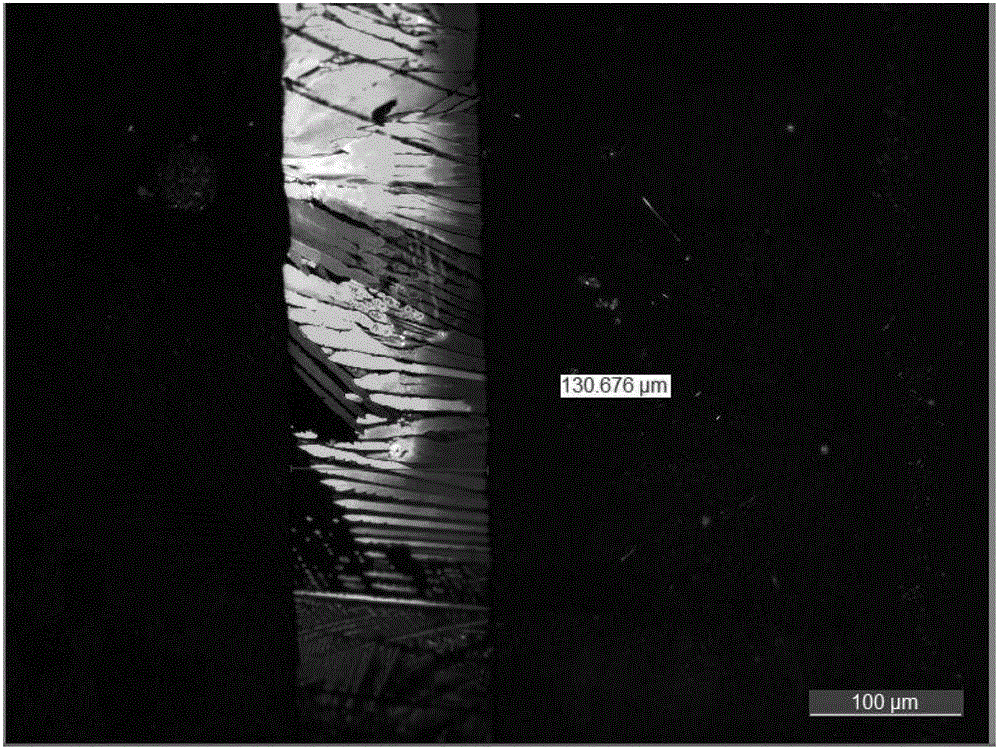

[0111] Dissolve Tips-pentacene and polystyrene (PS) with a mass ratio of 1:1 in chlorobenzene at 40°C, let it stand and filter to prepare the total mass of Tips-pentacene and polystyrene Divide a mixed solution with a concentration of 2%, titrate a sufficient amount of the solution on the edge of the silicon substrate, and slowly and evenly scrape the solution on the silicon substrate at a speed of 0.5mm / s to complete the selective patterning, and dry it overnight in a vacuum environment. Prepare the film. A metal baffle covers the self-assembled device, and a gold electrode with a thickness of 50-100 nm is prepared as a source-drain electrode by thermal evaporation.

Embodiment 2

[0113] Dissolve Tips-pentacene and polystyrene (PS) with a mass ratio of 1:1 in chlorobenzene at 40°C, let it stand and filter to obtain the total mass percentage of Tips-pentacene and polystyrene An organic solution with a concentration of 2%, titrate a sufficient amount of the solution on the edge of the silicon substrate, and slowly and evenly coat the solution on the silicon substrate at a speed of 5cm / s by means of an additional scraping device to complete the selective patterning, vacuum The environment was dried overnight to prepare a film. A metal baffle covers the self-assembled device, and a gold electrode with a thickness of 50-100 nm is prepared as a source-drain electrode by thermal evaporation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com