Laser processing device and laser processing method

A technology of laser processing device and laser light source, which is applied in laser welding equipment, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

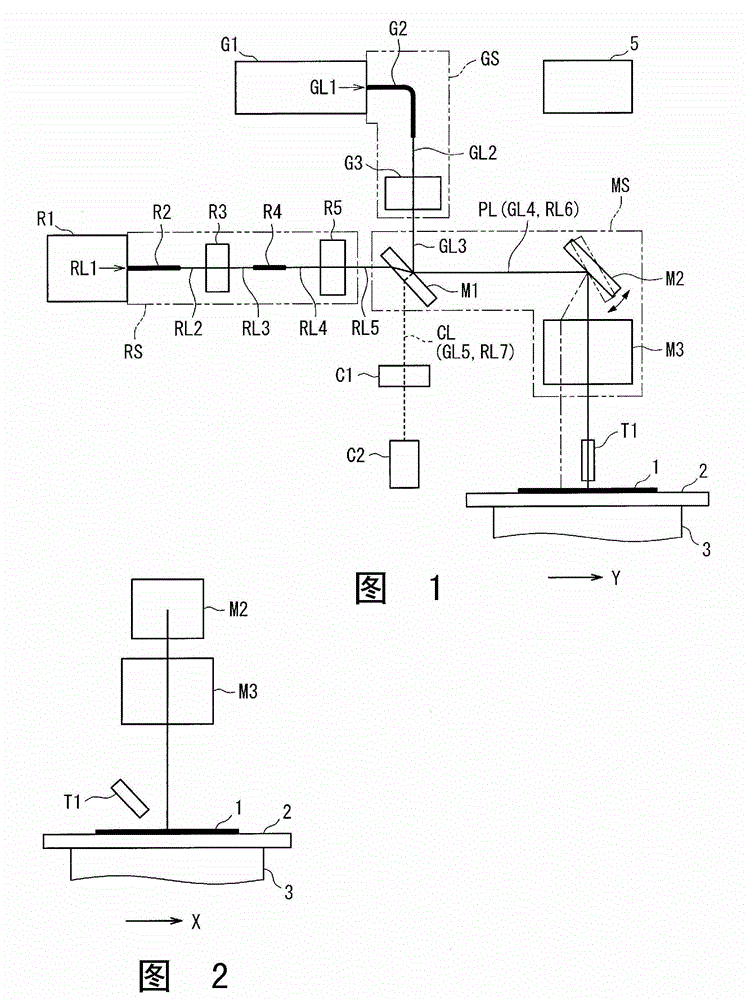

[0129] according to figure 1 , figure 2 A laser processing apparatus according to an embodiment of the present invention will be described.

[0130] The laser processing device of this embodiment includes: a visible laser light source G1 that outputs pulsed waves, that is, visible laser light GL1 , and a near-infrared laser light source R1 that outputs continuous waves, that is, near-infrared laser RL1 .

[0131] Visible laser light source G1 is, for example, a laser oscillator that performs pulse oscillation with an output power of 50W, a vibration frequency of 10kHz, and a pulse energy of 5mJ to generate green laser light with a wavelength of 532nm, which is a frequency doubled wave of YAG laser. In addition, the wavelength of the visible laser light of this invention is not limited to a specific value, For example, the wavelength of 355-577 nm can be illustrated.

[0132] In addition, the near-infrared laser light source R1 is, for example, a semiconductor laser that con...

Embodiment 2

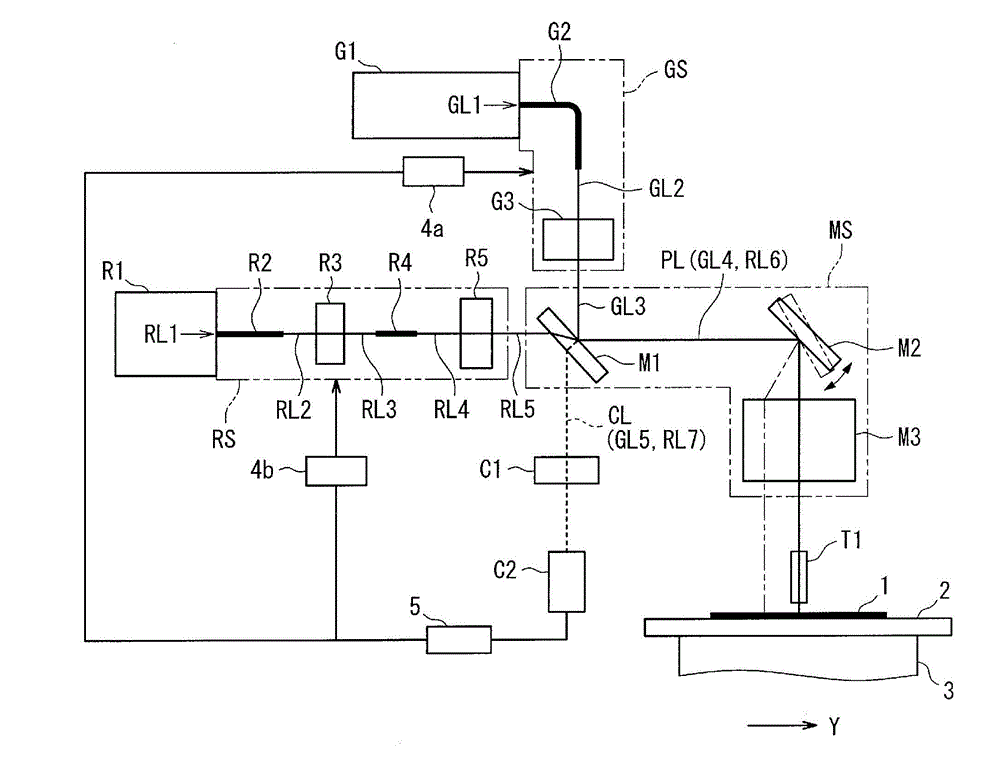

[0185] Next, according to Figure 4 A laser processing apparatus according to another embodiment of the present invention will be described. In addition, the same code|symbol is attached|subjected to the same structure as said Example 1, and the description is abbreviate|omitted or simplified.

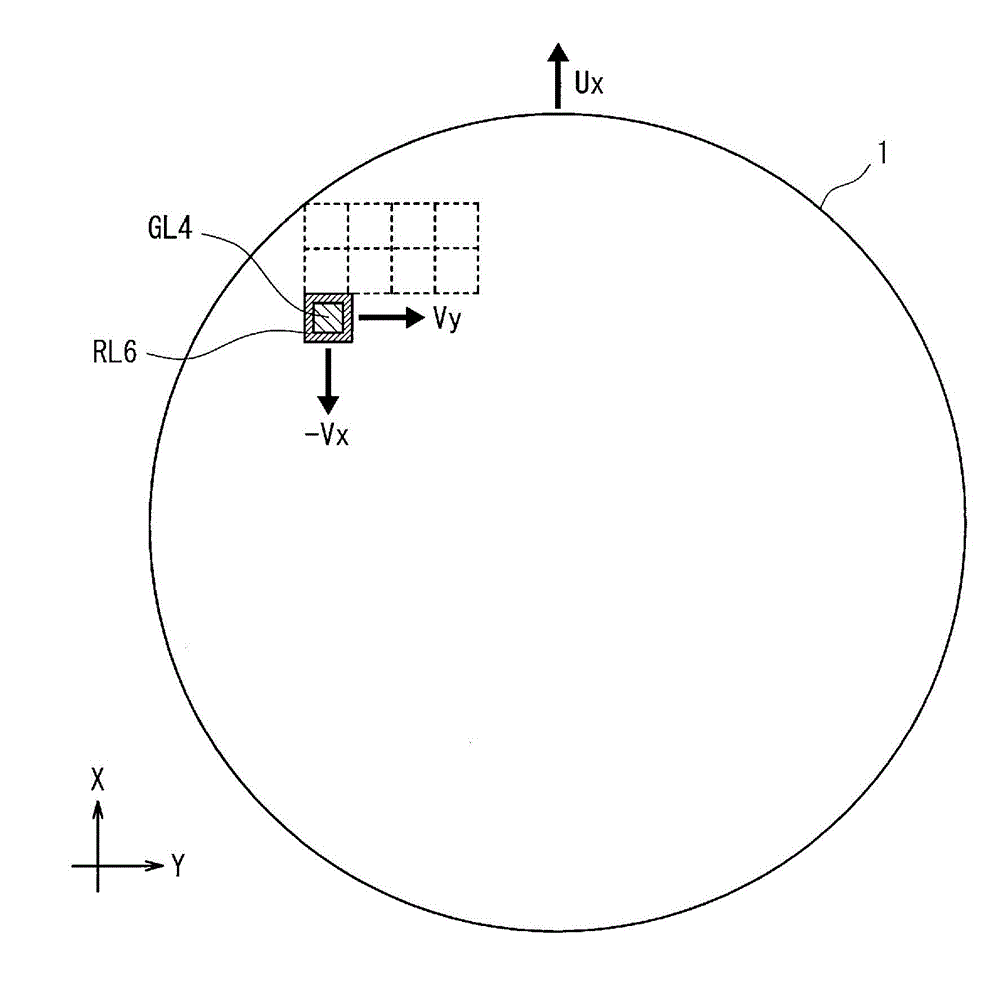

[0186] The irradiation positions of the visible laser GL4 and the near-infrared laser RL6 on the object 1 may not only be aligned with appropriate positions, but may also be offset from each other. If the irradiation positions of the two laser beams are shifted, there is a possibility that the processing cannot be performed properly. In this embodiment, there is provided a mechanism for adjusting the deviation of the irradiation positions of the visible laser light GL4 and the near-infrared laser light RL6.

[0187] In this embodiment, the optical fiber G2 and the collimator lens G3 constituting the visible light optical system GS are provided with an adjustment mechanism 4a for adju...

Embodiment 3

[0199] Next, according to Image 6 Another embodiment will be described. In addition, the same code|symbol is attached|subjected to the same structure as each said Example, and the description is simplified.

[0200] The laser processing device of this embodiment includes: a visible laser light source G1 outputting a pulse wave, that is, a visible laser GL10 , and a near-infrared laser light source R1 outputting a continuous wave, that is, a near-infrared laser RL10 .

[0201] In this embodiment, the visible laser light source G1 is, for example, pulsed with an output power of 50W, a vibration frequency of 10kHz, and a pulse energy of 5mJ to generate a green laser with a wavelength of 532nm and a pulse width of 100ns, which is a doubled wave of YAG laser. The wavelength of the visible laser light of the visible laser light source G1 is not limited to a specific wavelength, and examples thereof include wavelengths in the range of 355 to 577 nm.

[0202] Also, in this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com