Preparation method for amphiphilic polymer drug micelle with calcium phosphate shell

An amphiphilic polymer, drug-loaded micelle technology, which is applied in the directions of non-active ingredient medical preparations, active ingredients-containing medical preparations, pharmaceutical formulas, etc., to achieve no drug burst release phenomenon, easy operation, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

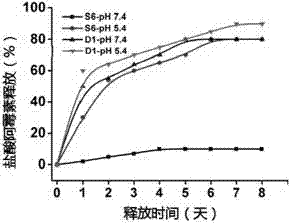

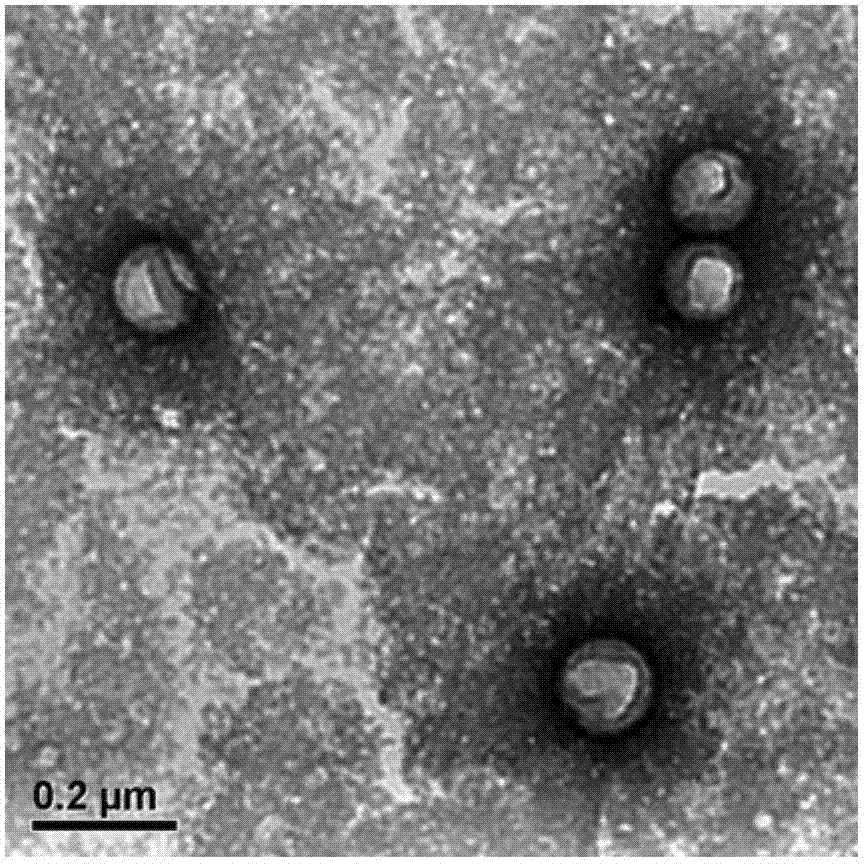

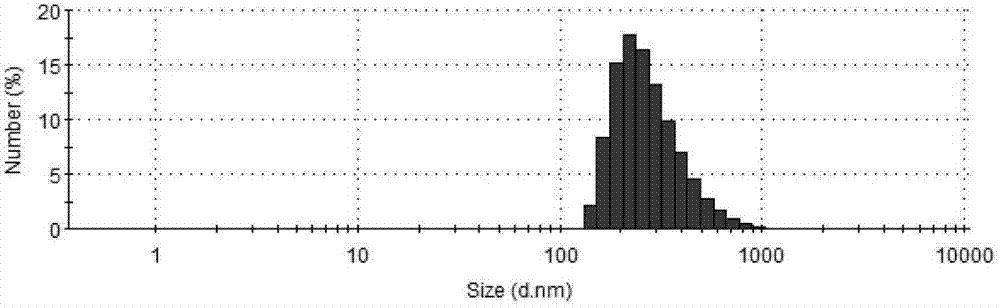

[0020] Dissolve 10 mg of amphiphilic polyethylene glycol-polylactic acid polymer in 1 mL of dichloromethane, and dissolve it completely under ultrasound. Weigh calcium chloride to prepare a 250 mM calcium chloride solution (pH 6.0). Use a pipette gun to draw 100 μL of calcium chloride solution and 100 μL of mitoxantrone solution (5 mg / mL) into the dichloromethane solution of the amphiphilic polymer, and the solution is separated. Ultrasonic emulsification was performed for 3 minutes in an ultrasonic cell pulverizer (ultrasound for 1 second, with an interval of 2 seconds) to form a primary emulsion. The primary emulsion was mixed with 3 mL of 2% (w / w) polyvinyl alcohol solution, and ultrasonic emulsification was continued for 5 minutes in an ultrasonic cell pulverizer (ultrasound for 1 second with an interval of 2 seconds) to form a double emulsion. Add the double emulsion dropwise to 10 mL of 0.3% (w / w) polyvinyl alcohol solution and stir to make it evenly dispersed. The dic...

Embodiment 2

[0022] Dissolve 10 mg of amphiphilic polyethylene glycol-polyphenylpropionic acid polymer in 1 mL of dichloromethane and dissolve it completely under ultrasound. Weigh calcium chloride to prepare a 50 mM calcium chloride solution (pH 7.5). Use a pipette gun to draw 100 μL of calcium chloride solution and 100 μL of 5-fluorouracil solution (1 mg / mL) into the dichloromethane solution of the amphiphilic polymer, and the solution is separated. Ultrasonic emulsification was performed for 3 minutes in an ultrasonic cell pulverizer (ultrasound for 1 second, with an interval of 2 seconds) to form a primary emulsion. The primary emulsion was mixed with 3 mL of 2% (w / w) polyvinyl alcohol solution, and ultrasonic emulsification was continued for 5 minutes in an ultrasonic cell pulverizer (ultrasound for 1 second with an interval of 2 seconds) to form a double emulsion. Add the complex emulsion dropwise to 10 mL of 0.3% (w / w) polyvinyl alcohol solution and stir to make it evenly dispersed...

Embodiment 3

[0024] Dissolve 10 mg of amphiphilic polyethylene glycol-polylactic acid polymer in 1 mL of dichloromethane, and dissolve it completely under ultrasound. Weigh calcium chloride to prepare a 100 mM calcium chloride solution (pH 7.0). Pipette 100 μL of calcium chloride solution and 100 μL of clindamycin solution (2 mg / mL) into the dichloromethane solution of the amphiphilic polymer, and the solution is separated. Ultrasonic emulsification was performed for 3 minutes in an ultrasonic cell pulverizer (ultrasound for 1 second, with an interval of 2 seconds) to form a primary emulsion. The primary emulsion was mixed with 3 mL of 2% (w / w) polyvinyl alcohol solution, and ultrasonic emulsification was continued for 5 minutes in an ultrasonic cell pulverizer (ultrasound for 1 second with an interval of 2 seconds) to form a double emulsion. Add the complex emulsion dropwise to 10 mL of 0.3% (w / w) polyvinyl alcohol solution and stir to make it evenly dispersed. The dichloromethane was r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com