A preparation method of ferromagnetic nanoparticles grafted on the surface of polyglycidol

A technology of polyglycidol and surface grafting, which is applied in the preparation of microspheres, microcapsule preparations, magnetic properties of inorganic materials, etc., can solve the problems of expensive raw materials and solvents, uneven particle size distribution, high cost and unsuitable for large-scale preparation, etc. problem, to achieve the effect of simple post-processing, low cost and strong magnetic responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing ferromagnetic nanoparticles (HPG-grafted MNPs) grafted on the surface of polyglycidol, the steps are as follows:

[0031] Add 2.33g of ferric oxalate pentahydrate into the three-necked flask, then add 4.66g of triethylene glycol (1:2) and mix evenly, react at 200°C for 1h, and react at 280°C for 1h, after naturally cooling to 25°C, add Glycidol monomers with a total volume percentage of 1:1 were mixed evenly and reacted at 50°C for 1 h. The final solution was precipitated with acetone to obtain HPG-grafted MNPs.

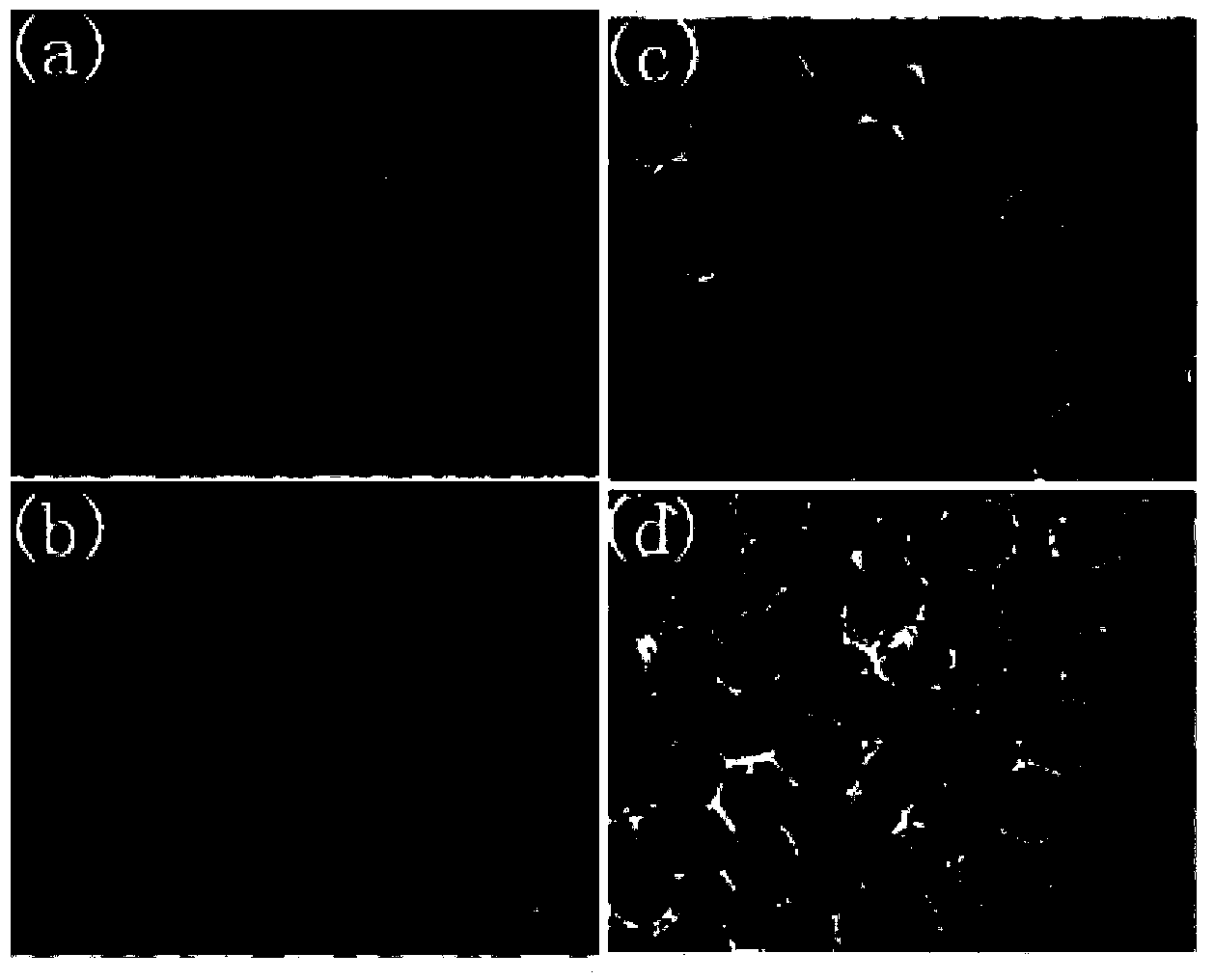

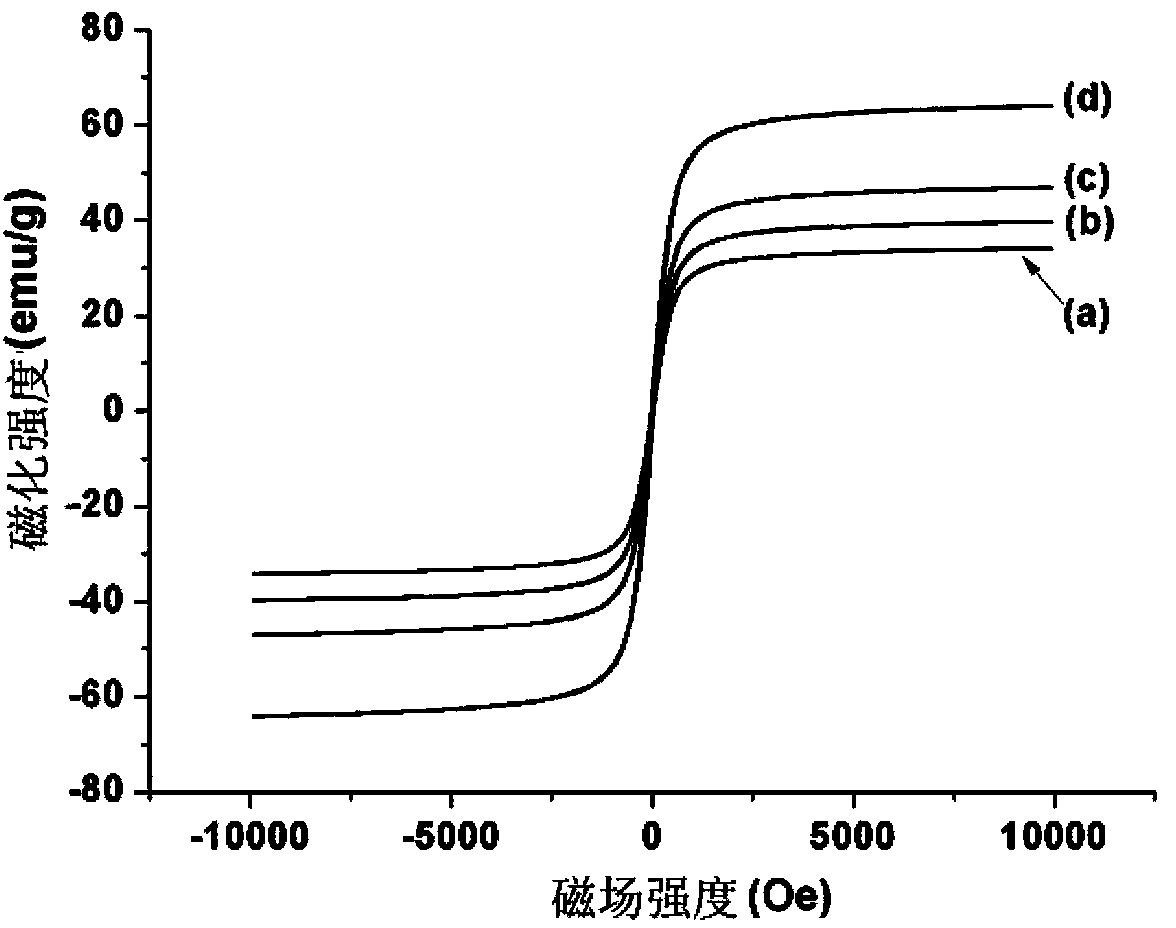

[0032] Such as figure 1 -(d) shows the transmission electron micrograph of ferromagnetic nanoparticles, and the figure shows that the particle size is 24nm. Such as figure 2 -Curve (d) shows the saturation magnetic flux of ferromagnetic nanoparticles, which shows that the saturation magnetic flux is 64.8wb.

Embodiment 2

[0034] A preparation method of ferromagnetic nanoparticles grafted on the surface of polyglycidol, the steps are as follows:

[0035] Add 2.33g of ferric oxalate pentahydrate into the three-necked bottle, then add 58.25g of triethylene glycol (1:25) and mix well, react at 200°C for 5h, and react at 290°C for 5h, cool naturally to 50°C, add The total volume percentage of glycidyl monomer is 1:50. After mixing evenly, react at 100°C for 12 hours, and finally obtain HPG-grafted MNPs after precipitation with acetone.

[0036] Such as figure 1 - (c) shows the transmission electron micrograph of ferromagnetic nanoparticles, and the figure shows that the particle size is 15nm. Such as figure 2 -Curve (c) shows the saturation magnetic flux of ferromagnetic nanoparticles, which shows that the saturation magnetic flux is 48.3wb.

Embodiment 3

[0038] A preparation method of ferromagnetic nanoparticles grafted on the surface of polyglycidol, the steps are as follows:

[0039] Add 2.33g of ferric oxalate pentahydrate into the three-necked bottle, then add 116.5g of triethylene glycol (1:50) and mix evenly, react at 200°C for 5h, and react at 290°C for 5h, cool naturally to 50°C, add The total volume percentage of glycidyl monomer is 1:50. After mixing evenly, react at 100°C for 12 hours, and finally obtain HPG-grafted MNPs after precipitation with acetone.

[0040] Such as figure 1 -(b) shows the transmission electron micrograph of ferromagnetic nanoparticles, and the figure shows that the particle size is 10nm. Such as figure 2 -Curve (b) shows the saturation magnetic flux of ferromagnetic nanoparticles, which shows that the saturation magnetic flux is 39.9wb.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com