Manufacturing method and application of poly brominated diphenyl ethers polluted soil in-situ remediation material

An in-situ repair and nano-technology, which is applied in the field of polluted environment remediation, can solve the problems of particle surface active site decline, nano-zero-valent iron easy to agglomerate, application hindrance, etc., and achieve easy promotion and use, convenient operation, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of dispersed nanometer Ni / Fe bimetallic particles, comprising the following steps:

[0034] 1) Dissolve iron salt or ferrous salt and polyvinylpyrrolidone in absolute ethanol, stir and mix well to obtain solution A, in which the mass ratio of iron salt or ferrous salt to polyvinylpyrrolidone is (0.5-3): 1;

[0035] 2) Dissolve the reducing agent in absolute ethanol, under the protection of protective gas, add it to solution A while stirring, continue to stir and react for 3 to 8 minutes, then separate the nanometer zero-valent iron, after washing, the nanometer zerovalent iron Iron was dissolved in absolute ethanol to obtain solution B;

[0036] 3) Dissolve nickel salt in absolute ethanol, add solution B, shake and react under the protection of protective gas for 15-60 minutes, separate metal particles, wash and dry to obtain dispersed nanometer Ni / Fe bimetallic particles.

[0037] The iron salt or ferrous salt used is FeSO 4 , FeCl 2 , Fe 2 (S...

Embodiment 1

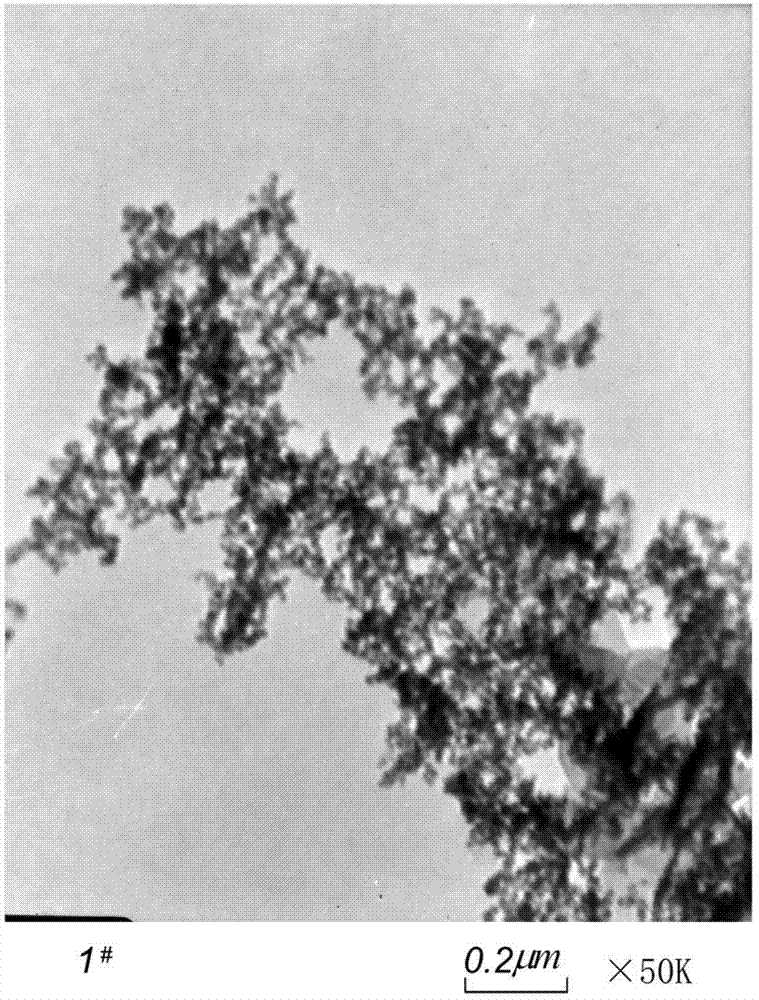

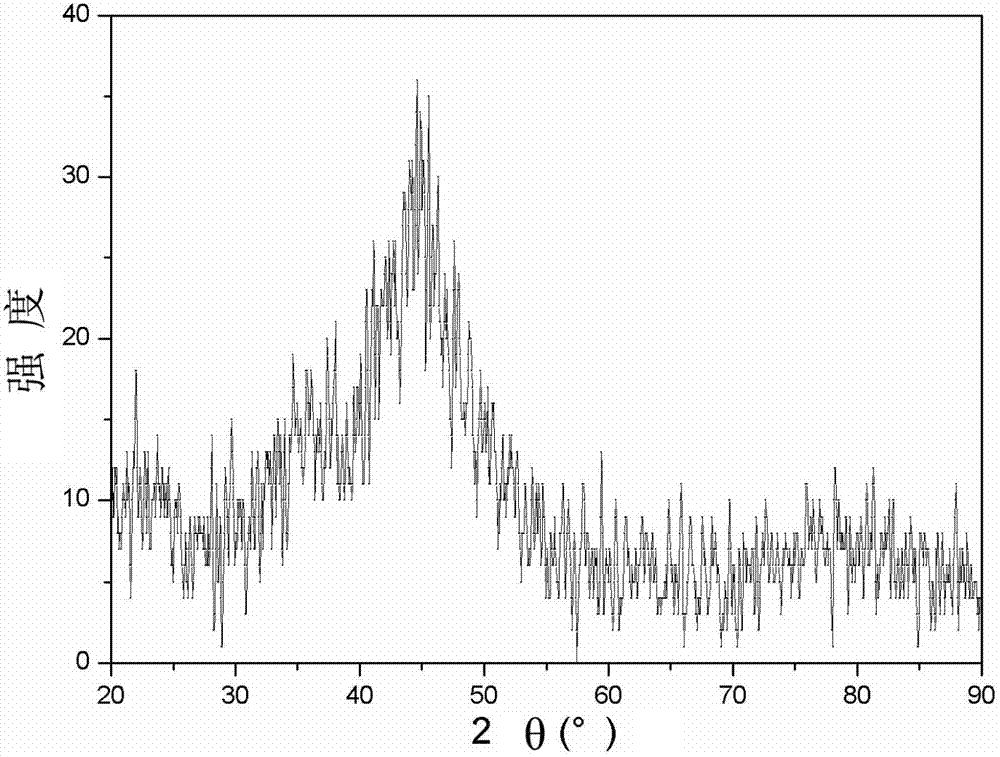

[0053] Preparation of dispersed nanometer Ni / Fe bimetallic particles:

[0054] 1) Prepare 100ml of 0.1mol / L FeSO with absolute ethanol 4 ·7H 2 0 solution, added with FeSO 4 ·7H 2 0 Polyvinylpyrrolidone K30 (PVP K30) of the same quality was stirred at a speed of 600rpm for 15min to dissolve and mix to obtain solution A;

[0055] 2) Prepare 50ml of 0.3mol / L sodium borohydride solution with absolute ethanol, under the protection of nitrogen, quickly add it to solution A under stirring, continue to stir and react at a speed of 600rpm for 5min, and then separate by magnetic separation Remove the nanometer zero-valent iron, wash with deoxygenated water and dehydrated ethanol respectively for 3 times, then dissolve and disperse the nanometer zerovalent iron in 50ml of dehydrated ethanol to obtain solution B;

[0056] 3) Prepare 50ml of 0.03mol / L NiCl with absolute ethanol 2 ·6H 2 O solution, add solution B, under the protection of nitrogen, stir the reaction at a speed of 250rp...

Embodiment 2

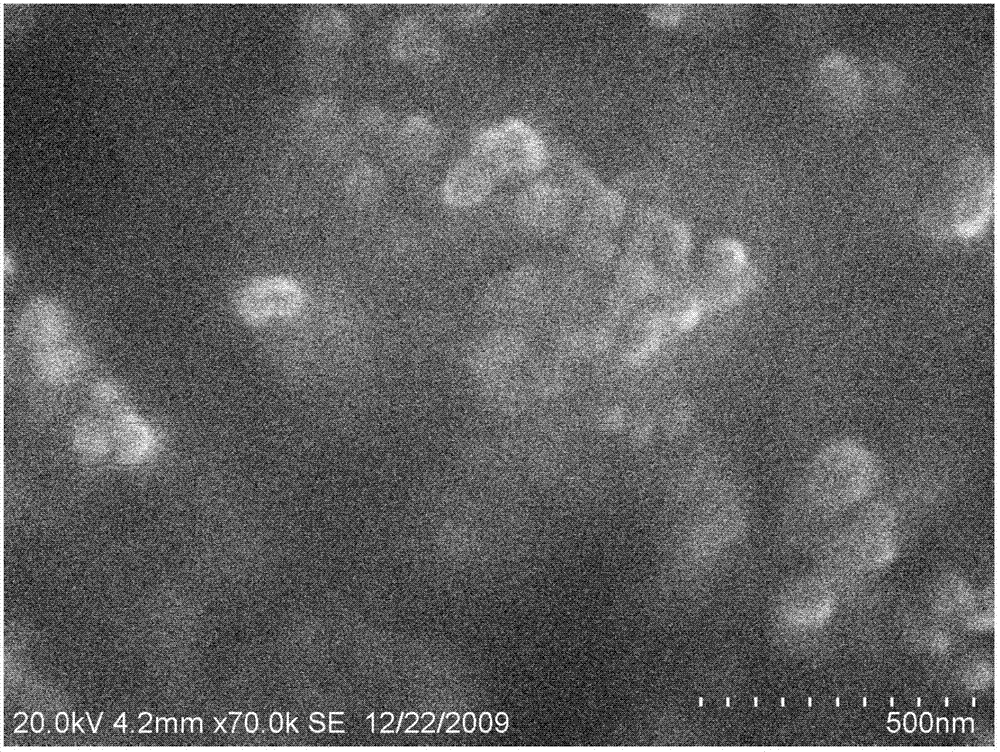

[0059] Preparation of dispersed nanometer Ni / Fe bimetallic particles:

[0060] 1) Prepare 100ml of 0.02mol / L FeCl with absolute ethanol 2 solution, add PVP K30, mass FeCl 2 0.5 times of that, stirred at 400rpm for 20min to dissolve and mix to obtain solution A;

[0061] 2) Prepare 35ml of 0.06mol / L KBH with absolute ethanol 4 The solution, under the protection of nitrogen, was quickly added to solution A under stirring, and continued to stir and react at a speed of 400rpm for 5 minutes, and then separated nanometer zero-valent iron by magnetic separation, and washed them with deoxygenated water and absolute ethanol respectively. After each wash 3 times, dissolve and disperse the nanometer zero-valent iron in 50ml of absolute ethanol to obtain solution B;

[0062] 3) Prepare 100ml of 0.01mol / L NiCl with absolute ethanol 2 ·6H 2 O solution, add solution B, under the protection of nitrogen, shake and react at a speed of 250rpm for 15min, let the nickel deposit on the iron su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com