Preparation method of superhigh-specific-area monodisperse polymer microspheres

An ultra-high specific surface area, monodisperse technology, which is applied in the field of preparation of monodisperse polymer microspheres, can solve the problems that the specific surface area of the product is not given, and there is little attention to the preparation of ultra-high specific surface area microspheres.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

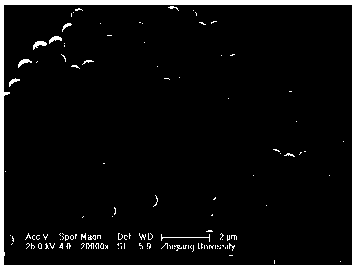

[0021] In a 250mL three-neck flask equipped with an argon gas line, mechanical stirring and condenser, add 9.5mL vinylbenzyl chloride (VBC), 0.5mL divinylbenzene (DVB), 0.1g cetyl alcohol (CA) , 100mL of deionized water and 0.132g of azobisisobutylamidine hydrochloride (AIBA), cooled in an ice bath, ultrasonically dispersed for 150s with a JY92 cell pulverizer, and the output power was 40%, and then quickly transferred to a heating oil bath, Heating to 70°C for 12 hours, the product was centrifuged and washed, then dried in a vacuum oven for 24 hours.

[0022] In a 250 mL three-neck flask equipped with an argon gas line, mechanical stirring and condenser, add 1.5 g of prepolymer microspheres, 120 mL of dichloromethane and 0.6 g of FeCl 3 , swelled and stirred at room temperature for 24 hours, then rapidly heated to 80 ° C for 8 hours, and after centrifugation, the product was washed with methanol, dilute nitric acid solution and deionized water, and dried in vacuum. The speci...

Embodiment 2

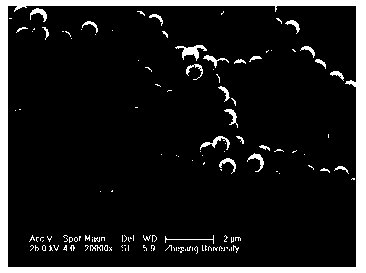

[0024] In a 250mL three-neck flask equipped with an argon gas line, mechanical stirring and condenser, add 9.0mL vinylbenzyl chloride (VBC), 0.5mL divinylbenzene (DVB), 0.5mL hydroxyethyl acrylate, 0.1g Cetyl alcohol (CA), 100mL deionized water and 0.132g azobisisobutylamidine hydrochloride (AIBA), cooled in an ice bath, ultrasonically dispersed for 150s with a JY92 cell pulverizer, output power 40%, and then quickly Transfer to a heating oil bath, heat to 70°C and react for 12 hours. After the product is centrifuged and washed, it is dried in a vacuum oven for 24 hours.

[0025] In a 250 mL three-neck flask equipped with an argon gas line, mechanical stirring and condenser, add 1.8 g of prepolymer microspheres, 120 mL of dichloromethane and 0.5 g of AlCl 3 , swelled and stirred at room temperature for 24 hours, then rapidly heated to 80 ° C for 8 hours, and after centrifugation, the product was washed with methanol, dilute nitric acid solution and deionized water, and dried i...

Embodiment 3

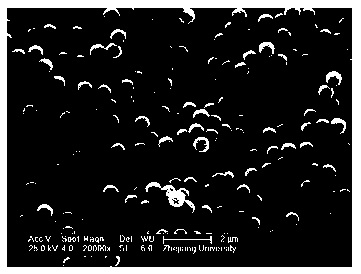

[0027] In a 250mL three-neck flask equipped with an argon gas line, mechanical stirring and condenser, add 8.0mL vinylbenzyl chloride (VBC), 0.5mL divinylbenzene (DVB), 1.5mL styrene, 0.1g hexadecane Alkanol (CA), 100mL deionized water and 0.132g azobisisobutylamidine hydrochloride (AIBA), cooled in an ice bath, ultrasonically dispersed for 150s with a JY92 cell pulverizer, output power 40%, and then quickly transferred to In a heating oil bath, heat to 70°C to react for 12 hours. After the product is centrifuged and washed, it is dried in a vacuum oven for 24 hours.

[0028] In a 250 mL three-neck flask equipped with an argon gas line, mechanical stirring and condenser, add 2.1 g of prepolymer microspheres, 120 mL of dichloromethane and 0.9 g of SnCl 4 , swelled and stirred at room temperature for 24 hours, then rapidly heated to 80 ° C for 8 hours, and after centrifugation, the product was washed with methanol, dilute nitric acid solution and deionized water, and dried in va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com