A kind of polyamide barrier material and preparation method thereof

A barrier material, polyamide technology, applied in the field of polyamide barrier material and its preparation, can solve the problems of high raw material cost, poor strength, no obvious improvement of barrier performance, etc., and achieve low raw material cost, high barrier property, mechanical strength The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (a) caprolactam dissolving polyamide 66, polyvinyl alcohol stage

[0043] Heat 795 parts by weight of caprolactam to 160°C, under the protection of nitrogen gas, add 100 parts by weight of polyamide 66, stir for 90 minutes, then add 100 parts by weight of polyvinyl alcohol, and stir for 45 minutes.

[0044] (b) Water removal stage

[0045] Turn on the vacuum pump, and vacuumize for 20 minutes at 150°C.

[0046] (c) Casting stage

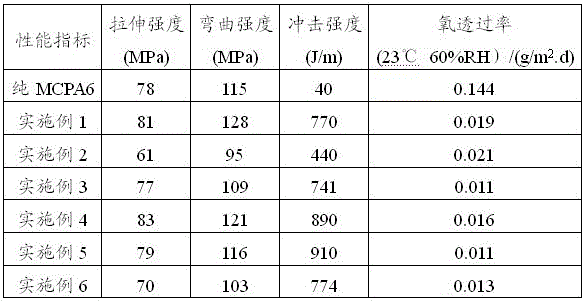

[0047] Add 2 parts by weight of sodium hydroxide and 3 parts by weight of toluene diisocyanate into the above mixture, mix quickly and uniformly, pour into a mold for casting; the casting temperature is 160° C., and react for 15 minutes. The obtained polyamide barrier material was subjected to a performance test, and the specific performance test results are shown in Table 1.

Embodiment 2

[0049] (a) Caprolactam dissolving polyvinyl alcohol stage

[0050] Heat 948 parts by weight of caprolactam to 160°C, add 50 parts by weight of polyvinyl alcohol under the protection of carbon dioxide gas, and stir for 10 minutes.

[0051] (b) Water removal stage

[0052] Turn on the vacuum pump, and vacuumize for 10 minutes at 140°C.

[0053] (c) Casting stage

[0054] Add 1 part by weight of sodium cyanide and 1 part by weight of toluene diisocyanate to the above mixture, mix quickly and uniformly, pour into a mold for casting; casting temperature is 180°C, and react for 5 minutes. The obtained polyamide barrier material was subjected to a performance test, and the specific performance test results are shown in Table 1.

Embodiment 3

[0056] (a) caprolactam dissolving polyamide 66, polyvinyl alcohol stage

[0057] Heat 670 parts by weight of caprolactam to 180°C, under the protection of nitrogen gas, add 150 parts by weight of polyamide 66, stir for 120 minutes, then add 150 parts by weight of polyvinyl alcohol, and stir for 40 minutes.

[0058] (b) Water removal stage

[0059] Turn on the vacuum pump, and vacuumize for 30 minutes at 160°C.

[0060] (c) Casting stage

[0061] Add 10 parts by weight of sodium caprolactam, 10 parts by weight of triphenylmethane triisocyanate, 2 parts by weight of antioxidant 1010, 3 parts by weight of antioxidant 168, and 5 parts by weight of light stabilizer 442 into the above mixture, mix quickly and uniformly, Pour into a mold for casting; the casting temperature is 180°C, and the reaction takes 5 minutes. The obtained polyamide barrier material was subjected to a performance test, and the specific performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com