Anisotropic conductive film composition, the anisotropic conductive film thereof and semiconductor device

An anisotropic, conductive film technology that is used in the fields of anisotropic conductive films and semiconductor devices, resin compositions, and films to achieve excellent adhesion, prevent reduction in electrical connection reliability, and improve fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

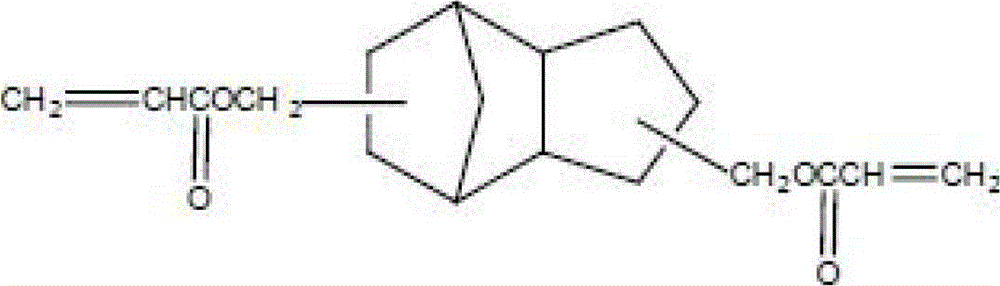

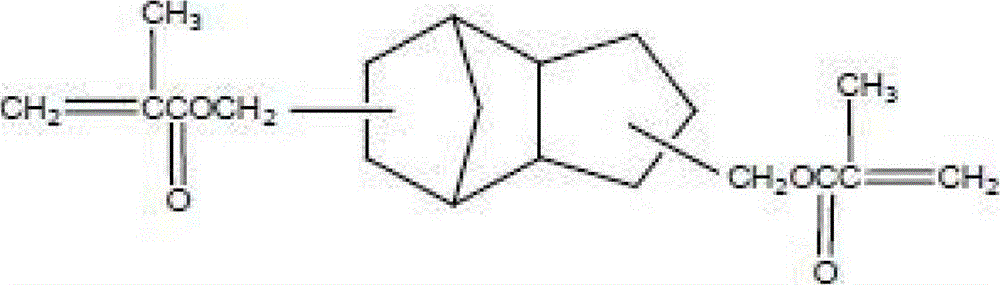

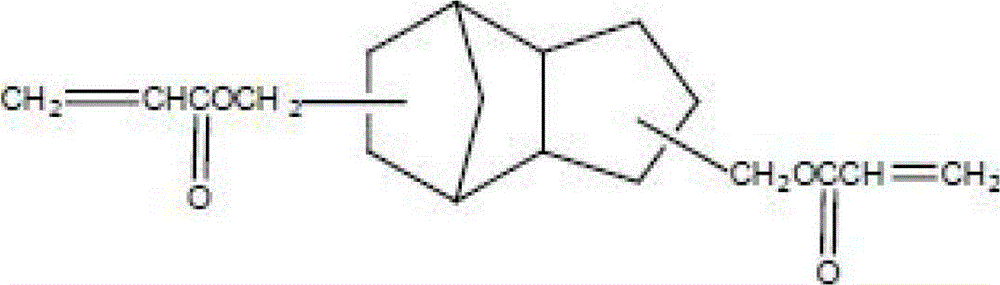

Image

Examples

Embodiment 1 to 5

[0107] Examples 1 to 5: Preparation of anisotropic conductive film

[0108] Add urethane resin, EVA copolymer, tricyclodecane dimethanol diacrylate, organic particles, organic peroxide, conductive particles and toluene as solvent according to the composition listed in Table 1 in the planetary mixer, dissolve and After dispersion, the solution was applied onto a release-treated PET film and dried by heating to 60° C. for 5 minutes in a forced convection oven to evaporate the solvent, thereby preparing an anisotropic conductive film having a thickness of 35 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com