Phosphogypsum processing method

A processing method and phosphogypsum technology are applied in the field of phosphorus chemical industry to achieve the effect of realizing recycling, reducing environmental protection pressure and realizing comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

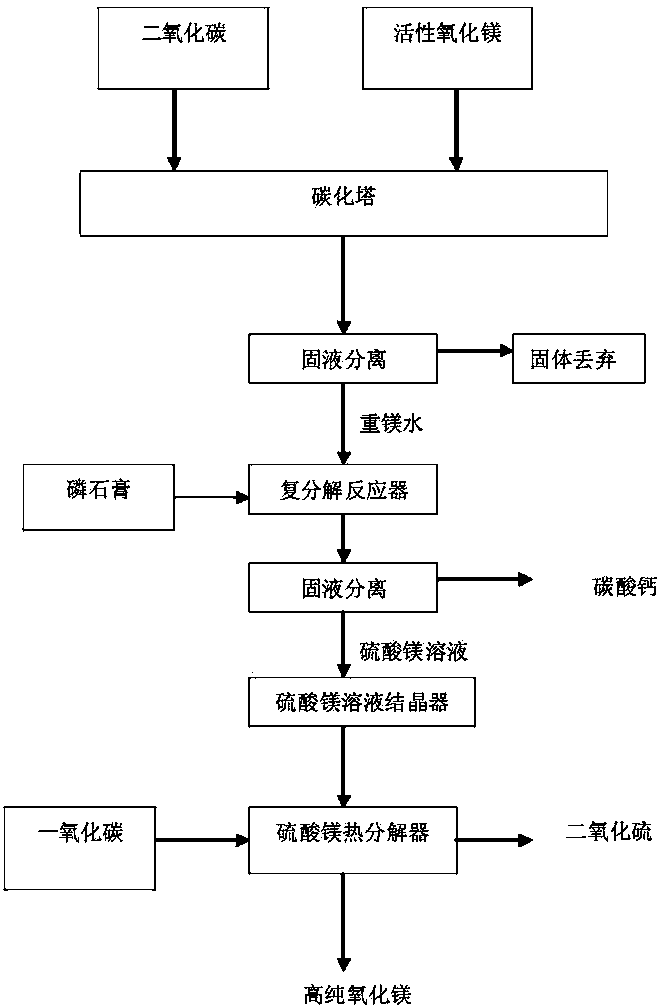

[0026] Activated magnesia is carbonized with carbon dioxide in a carbonization tower, and then solid-liquid separation is performed to obtain liquid-phase heavy magnesium water, and then phosphogypsum and heavy magnesium water are subjected to metathesis reaction to obtain liquid-phase magnesium sulfate solution after solid-liquid separation, and then magnesium sulfate solution Evaporate and crystallize to obtain magnesium sulfate heptahydrate crystals, and finally reduce and thermally decompose the magnesium sulfate heptahydrate crystals with 1.2 times the molar amount of carbon monoxide to obtain sulfur dioxide and high-purity magnesium oxide.

[0027] Described carbon dioxide, its volume percentage is 50-90%.

[0028] The activated magnesia has an activity of 60%-90% using the hydration method.

[0029] The carbon monoxide is 60-95% by volume.

[0030] Through the above operations, the purity of the obtained high-purity magnesium oxide is 98-99.5%.

Embodiment 2

[0032] Activated magnesia is carbonized with carbon dioxide in a carbonization tower, and then solid-liquid separation is performed to obtain liquid-phase heavy magnesium water, and then phosphogypsum and heavy magnesium water are subjected to metathesis reaction to obtain liquid-phase magnesium sulfate solution after solid-liquid separation, and then magnesium sulfate solution Evaporate and crystallize to obtain magnesium sulfate heptahydrate crystals, and finally reduce and thermally decompose the magnesium sulfate heptahydrate crystals with 2 times the molar amount of carbon monoxide to obtain sulfur dioxide and high-purity magnesium oxide.

[0033] Described carbon dioxide, its volume percentage is 80%.

[0034] The activated magnesium oxide has an activity of 85% using the hydration method.

[0035] The carbon monoxide is 90% by volume.

[0036] Through the above operations, the purity of the obtained high-purity magnesium oxide is 99.2%.

Embodiment 3

[0038] Activated magnesia is carbonized with carbon dioxide in a carbonization tower, and then solid-liquid separation is performed to obtain liquid-phase heavy magnesium water, and then phosphogypsum and heavy magnesium water are subjected to metathesis reaction to obtain liquid-phase magnesium sulfate solution after solid-liquid separation, and then magnesium sulfate solution Evaporate and crystallize to obtain magnesium sulfate heptahydrate crystals, and finally reduce and thermally decompose the magnesium sulfate heptahydrate crystals with 1.5 times the molar amount of carbon monoxide to obtain sulfur dioxide and high-purity magnesium oxide.

[0039] Described carbon dioxide, its volume percentage is 50%.

[0040] The activated magnesium oxide has an activity of 65% using the hydration method.

[0041] The carbon monoxide is 60% by volume.

[0042] Through the above operations, the purity of the obtained high-purity magnesium oxide is 98.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com