Sample preparation instrument

A technology of sample preparation and nitrogen blowing plate, which is applied in the field of chemical analysis and pharmaceutical analysis, can solve the problems of poor sample repeatability, large space occupation, and low frequency of use, so as to save laboratory space, be easy to carry and move, and avoid The effect of introducing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

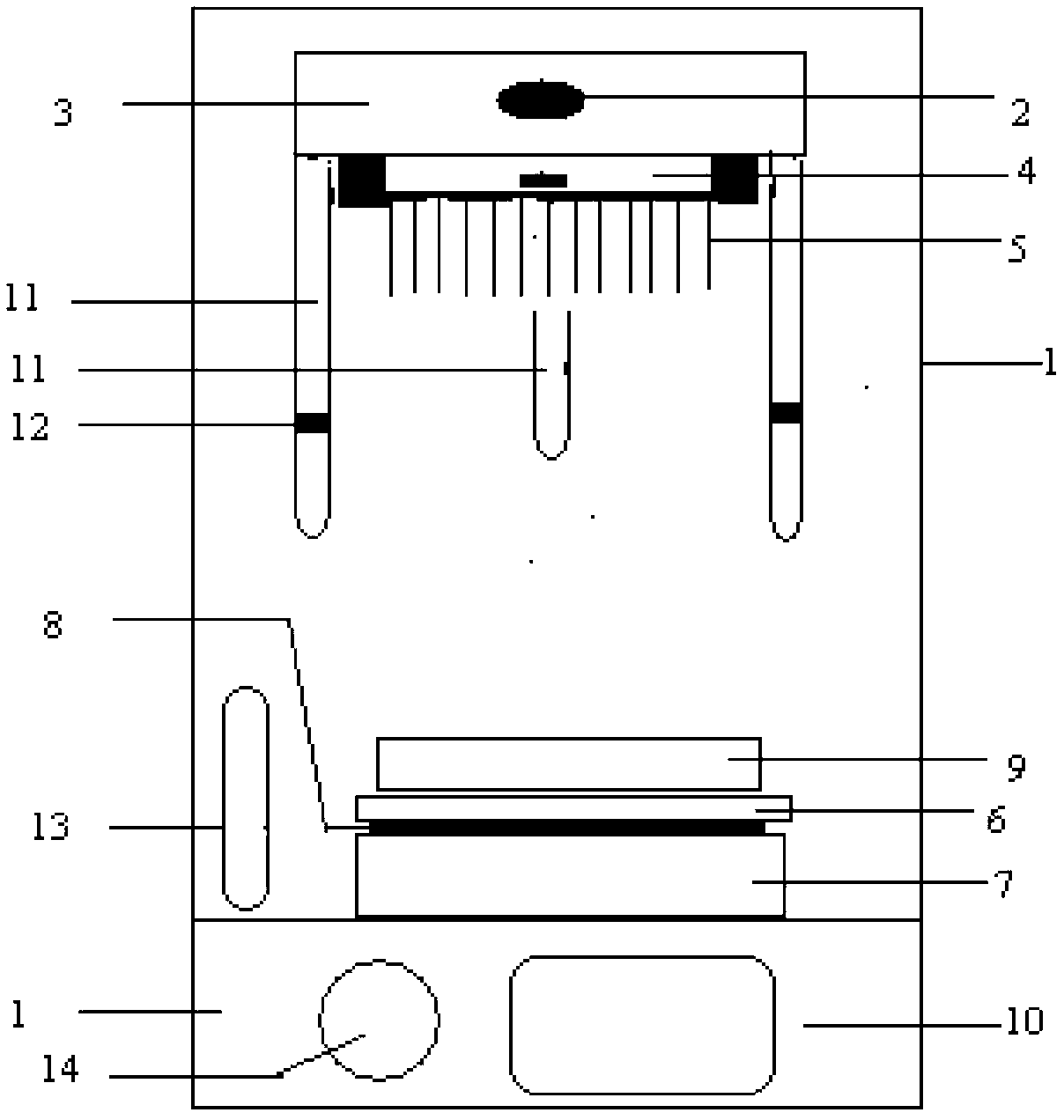

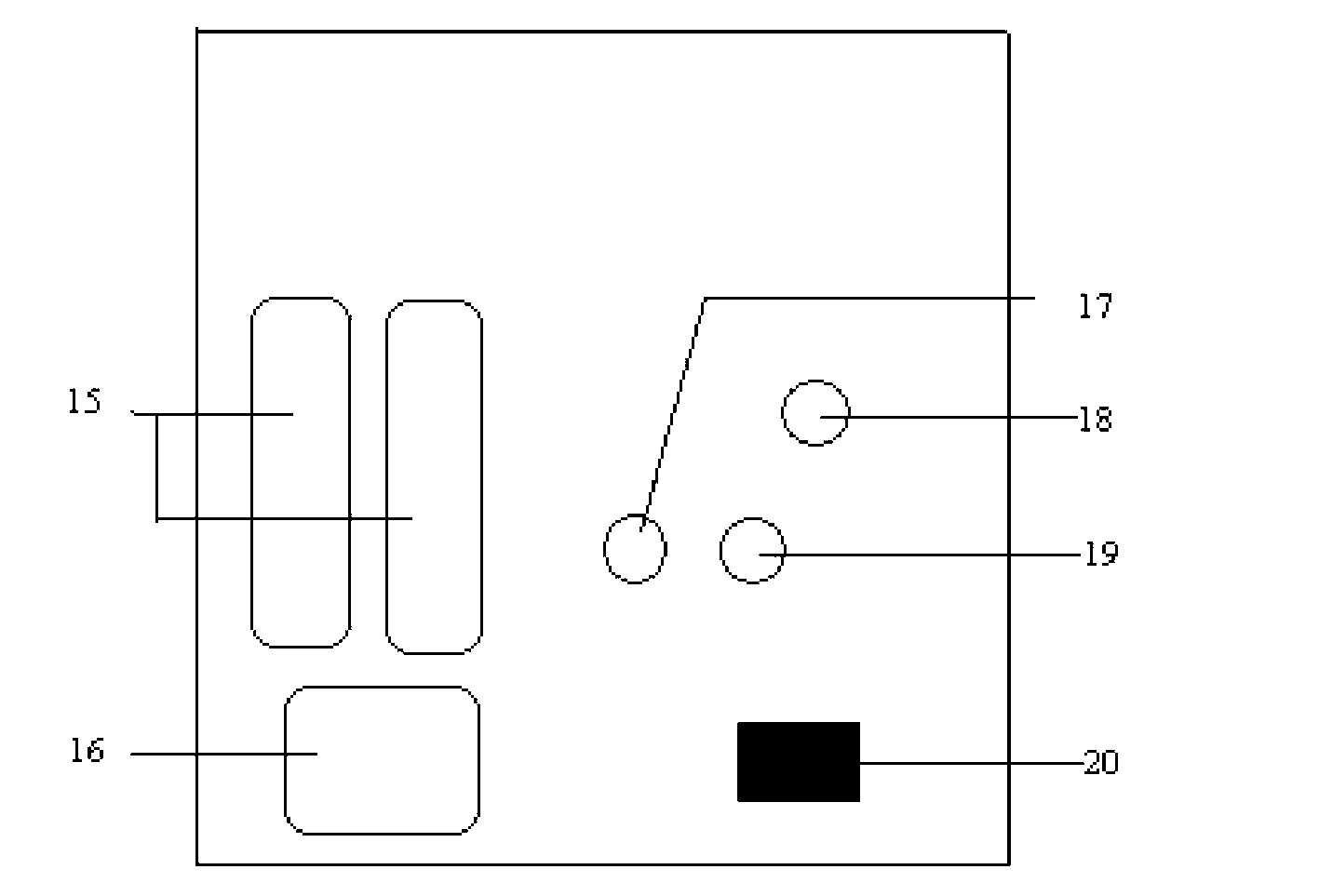

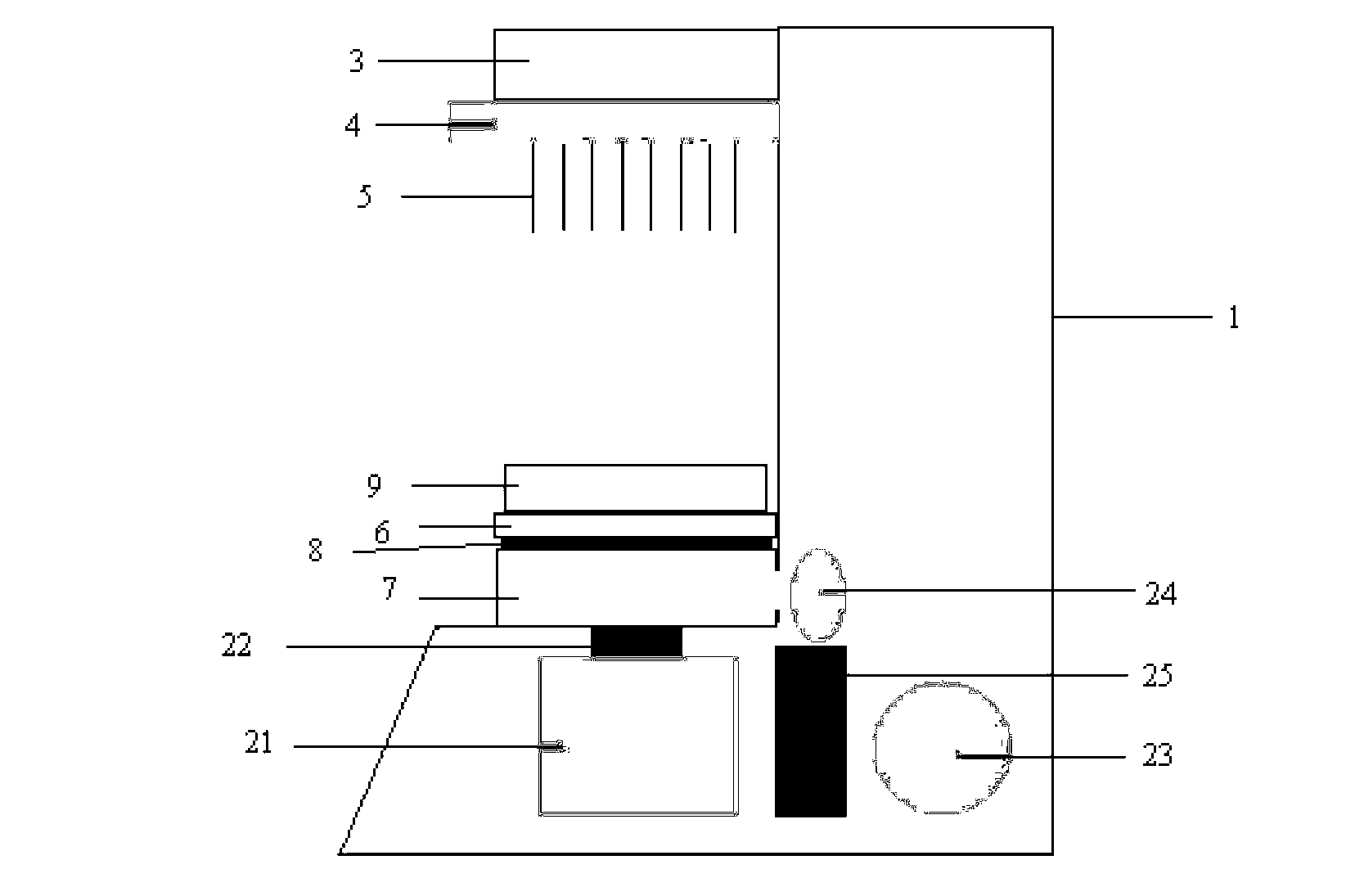

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1: SPE operation process

[0091] C18 bonded silica filler, 2mL 96-well plate with a specification of 100mg filler / well Operation procedure:

[0092] Placement of sample preparation 96-well C18 packing plate: fix a 2mL 96-well C18 packing plate in the second fixing tank 6 where the upper pretreatment plate of the solid-phase extraction device is placed, so that it completely matches the surrounding. Note that the receiving device below is not put away for the time being, and ensure that the 96-well plate is completely consistent with the surroundings, so as to ensure the sealing of the entire part of the solid-phase extraction.

[0093] Activation: add 2mL of methanol to each well, after adding 1mL for the first time, after equilibrating for 1min, vacuumize to make it flow out, then add 1mL of methanol to activate, and after equilibrating for 1min, vacuumize to make it flow out. Then add 2 mL of water to each well, and activate according to the steps of addi...

Embodiment 2

[0100] Example 2: Medium liquid-liquid extraction (SLE) operation process

[0101] For the operation process of medium-liquid-liquid extraction, the specifications of the 96-well SLE plate used are: 2 mL SLE 96-well plate with a filler content of 200 mg / well.

[0102] Place the receiving plate: place the receiving plate in the groove of the first fixed groove 7 where the receiving plate is placed in the solid phase extraction device.

[0103] Placement of the 96-well SLE plate of the sample preparation plate: Fix the 2mL 96-well SLE plate in the second fixing groove 6 where the upper pretreatment plate of the solid-phase extraction device is placed, so that it completely matches the surrounding.

[0104] Sample loading: pipette 200 μL of 200 μg / mL propylparaben aqueous solution, and load the sample into the SLE column hole. Note: the maximum sample volume should ensure that the sample cannot flow out, and equilibrate for 5 minutes.

[0105] Extraction: pipette 1mL of dichloro...

Embodiment 3

[0108] Example 3: Operation process of novel protein precipitation technology

[0109] In the operation process of rapid protein precipitation technology, the size of the 96-well plate used is 1 mL permeable plate.

[0110] Putting in the receiving plate: placing the receiving plate in the first fixing groove 7 where the receiving plate is placed in the solid phase extraction device.

[0111]Placement of the 96-well PPT plate of the sample preparation plate: fix a 1mL 96-well PPT plate in the second fixing groove 6 of the upper pretreatment plate of the solid-phase extraction device, and ensure that the 96-well plate is completely consistent with the surrounding to ensure that the solid phase Extract the tightness of the entire section.

[0112] Sample loading: pipette 1mL of acetonitrile into the 96-well PPT sample preparation plate with a 96 pipette tip, then pipette 200μL of the sample solution to be treated into the sample well containing 1mL of acetonitrile, shake for 2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com