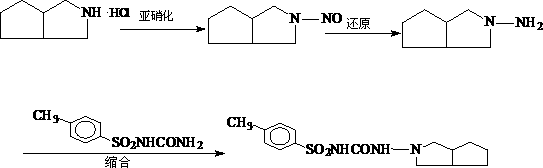

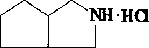

Purification method of 3-azabicyclo-octane hydrochloride

A technology of cyclooctane hydrochloride and purification method, which is applied in the field of solid purification of 3-azabicyclo[3.3.0]octane hydrochloride, and can solve the problems of unfavorable transportation, low purity and low content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put 60g potassium borohydride, 176g anhydrous zinc chloride, 415g dried toluene, and 138g THF into a 2000mL reaction flask at room temperature, mix and protect with nitrogen, and add 50g 1,2-cyclopentadicarboximide in batches , Mix and stir, slowly increase the temperature to 70°C for 4 hours, then slowly increase the temperature to 95~105°C, keep reflux and react for 10 hours to complete the reaction, change the distillation device to evaporate 35% of the organic solvent, then cool to 40°C and add slowly NaOH solution (30%) 800g to pH 13~14, steam distilled to distillate PH=7~8, fractions were extracted three times with 600ml toluene, combined toluene layer was acidified with refined hydrochloric acid to pH=1.5~2, heating Atmospheric reflux to remove the water in the toluene layer, cooling and suction filtration to obtain the crude azabicyclic solid. The crude product was heated and refluxed with a mixed solvent of 100g of ethanol and 100g of methyl acetate to obtain 51...

Embodiment 2

[0020] Put 60g potassium borohydride, 176g anhydrous zinc chloride, 415g dried toluene, and 104g THF into a 2000mL reaction flask at room temperature, mix and protect with nitrogen, and add 50g 1,2-cyclopentadicarboximide in batches , Mix and stir, slowly heat up to 75°C for 4h, keep warm at 95~105°C and reflux for 10 hours to complete the reaction, change the distillation device to evaporate 35% of the organic solvent, then cool down to 40°C, add slowly NaOH solution (30%) 800g to pH 13~14, steam distilled until the distillate PH=7~8, the fractions were extracted three times with 600ml xylene, the combined xylene layer was acidified with refined hydrochloric acid to pH=1.5~2 , The water in the toluene layer was removed by reflux at normal pressure at elevated temperature, and the crude azabicyclic solid product was obtained by suction filtration at lower temperature. The crude product was heated and refluxed for 30 minutes with a mixed solvent of 10g methanol and 100g ethyl ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com