Calcium zinc heat stabilizer used for PVC, zinc-containing compound and application

A technology of zinc compounds and heat stabilizers, applied in the direction of zinc organic compounds, etc., to achieve the effects of easy availability of raw materials, prolongation of zinc burning time, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of zinc-containing compound 1: bis(imidazole)-bis(o-hydroxybenzoic acid)-zinc

[0021] Sequentially add 50.0 g to a 1 L three-necked bottle Basic zinc carbonate, 121.0 g o-hydroxybenzoic acid, 89.0 g imidazole, 400.00 g absolute ethanol. Heat to 60 °C, stir, and keep at reflux for 2 h. The system was concentrated to about 100 mL by distillation under reduced pressure, and the system was lowered to room temperature, and the target product was precipitated from the liquid phase. The product was filtered, washed with a small amount of ethanol, and kept in a desiccator. The filtrate was reused.

Embodiment 2

[0023] Preparation of zinc-containing compound two: bis(1,2-dimethylimidazole)-bis(o-hydroxybenzoic acid)-zinc

[0024] 50.0 g of zinc oxide, 170.0 g of o-hydroxybenzoic acid, and 300 g of water were sequentially added into a 1 L three-necked flask. Heat to 80 °C and stir for 0.5 h. 120.0 g dimethylimidazole was added to the system, and the target product was precipitated from the liquid phase. The target product was filtered, washed with a small amount of ethanol, and kept in a desiccator.

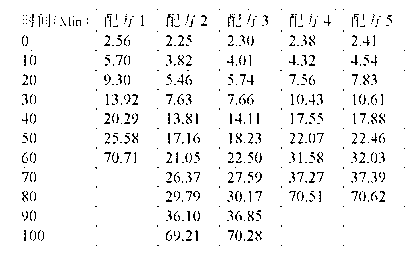

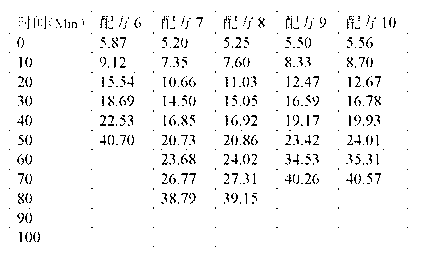

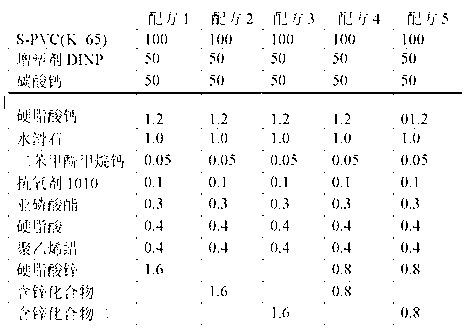

[0025] The use effect of the heat stabilizer of the present invention will be illustrated below in conjunction with the PVC composition formulations 1-5 (Table 1) of the application example group 1, and the PVC test pieces and aging tests are made after plasticizing by a two-roller plasticizer. In Table 1, the unit is gram, and the part below the three horizontal lines in column 2-5 of the formula is each component and consumption of the heat stabilizer of the present invention, and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com