Preparation method for multi-element polymerized gel

A polymer gel, multi-component technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of polyacrylamide degradation and damage, poor adhesion of the pipe wall, low colloidal strength, etc., and achieve low viscosity of the base fluid. , Low cost, strong resistance to pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Synthesis of graft copolymer: Dissolve 1.5% sodium carboxymethylcellulose in deionized water, after fully swelling, add 10% acrylamide, 3% 2-acrylamido-2-methylpropanesulfonic acid, 1.8 % acrylic acid (dissolve 2-acrylamide-2-methylpropanesulfonic acid and acrylic acid in 0.5% sodium hydroxide solution first, then add the above solution after cooling), 7% acryloyloxyethyl trimethyl chloride ammonium, the temperature was raised to 45°C, and then the initiator was added, and the reaction was stirred for 8 hours to obtain the product.

[0033] The configuration of the base liquid: cut the synthesized graft copolymer into small particles, configure it into a 2% solution, and stir until it is completely dissolved.

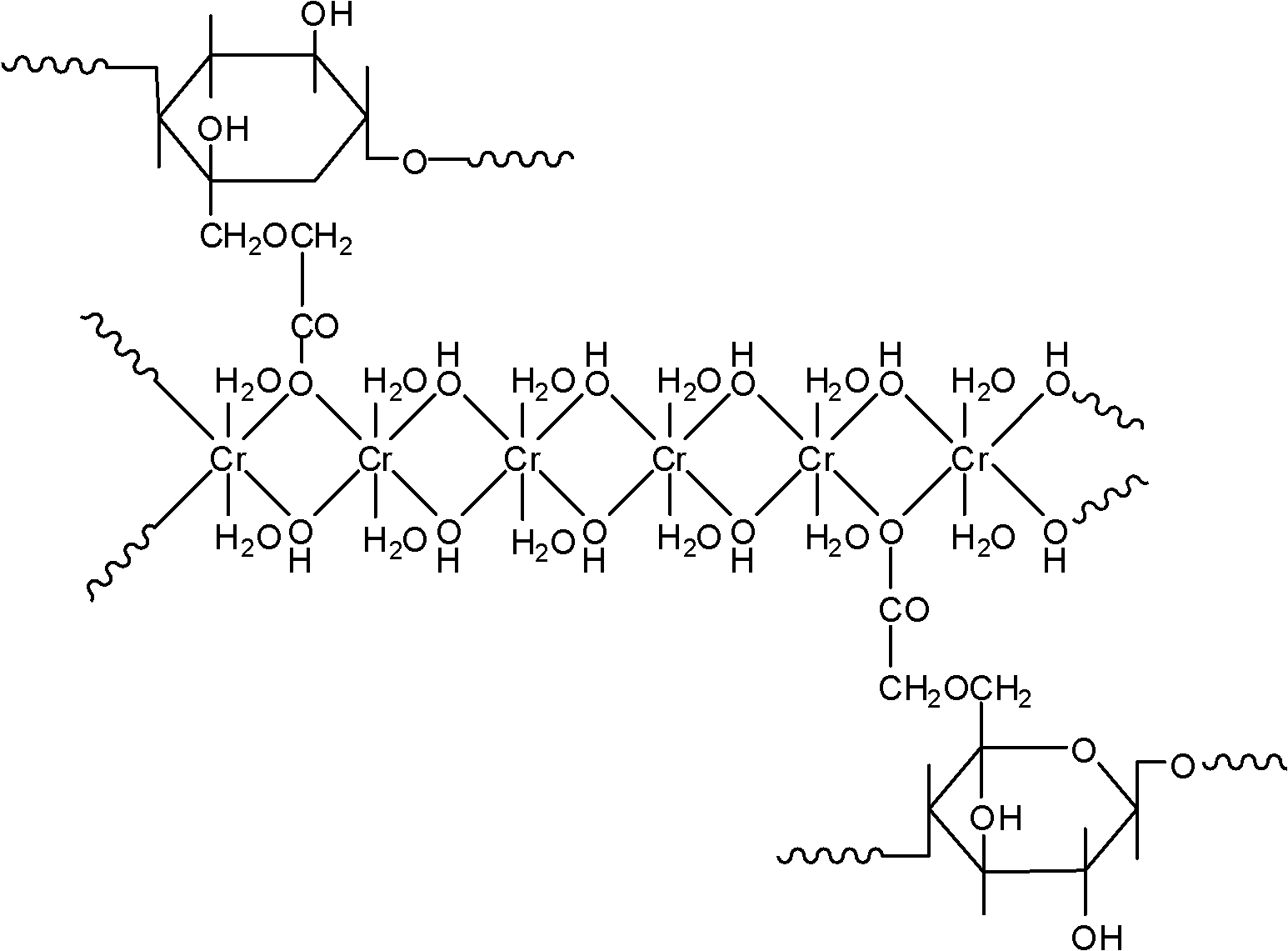

[0034] Formation of multi-component polymeric gel: add 0.02% chromium potassium sulfate, 0.02% ammonium persulfate and 0.01% sodium bisulfite to the base fluid, place it in a simulated wellbore at 80°C, and the viscosity after gelation is 97105mPa· s, the modulu...

Embodiment 2

[0036] Synthesis of graft copolymer: Dissolve 5% sodium carboxymethylcellulose in deionized water, after fully swelling, add 20% acrylamide, 8% 2-acrylamido-2-methylpropanesulfonic acid, 6 % acrylic acid (dissolve 2-acrylamide-2-methylpropanesulfonic acid and acrylic acid in 0.5% sodium hydroxide solution first, then add the above solution after cooling), 20% acryloyloxyethyl trimethyl chloride ammonium, the temperature was raised to 45°C, and then the initiator was added, and the reaction was stirred for 8 hours to obtain the product.

[0037] Configuration of base liquid: cut the synthesized graft copolymer into small particles, configure it into a 1.5% solution, and stir until completely dissolved.

[0038] Formation of multi-component polymer gel: add 0.02% potassium chromium sulfate and 0.025% ammonium persulfate to the base fluid, place it in a simulated wellbore at 60°C, the viscosity after gelation is 77600mPa·s, and the elastic modulus is 3590Pa , the pressure bearin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com