Synthetic method of polycarboxylic acid type highly slump loss resistant water-reducing agent

A synthesis method and technology of water reducer, which is applied in the synthesis of polycarboxylate water reducer for concrete and polycarboxylate high slump retention water reducer, can solve the problems of insufficient slump retention ability of water reducer, Achieve the effects of low cost, cost saving and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

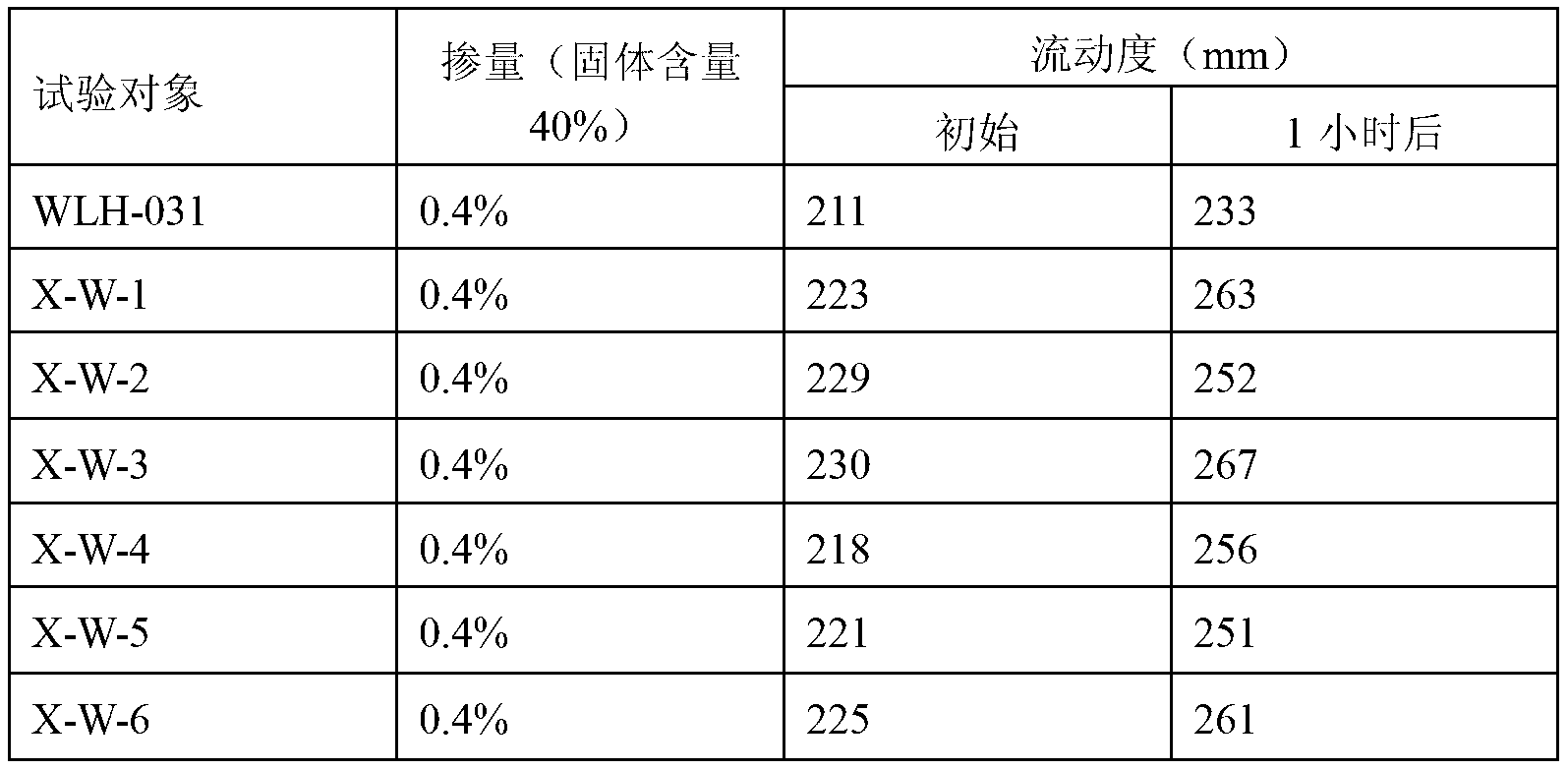

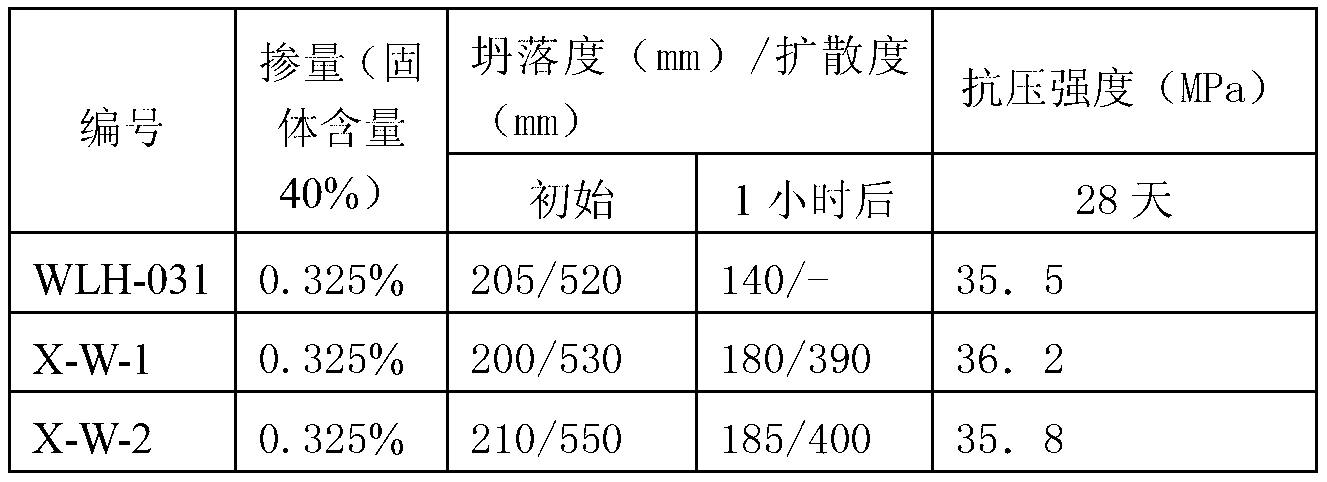

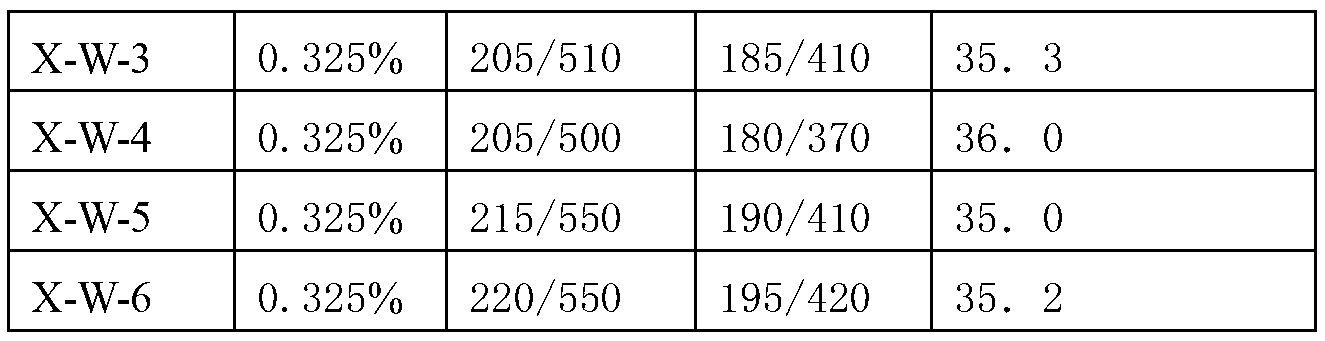

Examples

Embodiment 1

[0029] A kind of synthetic method of polycarboxylic acid type high slump water reducer, its steps are as follows:

[0030] The first step, preparation of treated water: add water treatment agent acrylic acid-maleic anhydride copolymer (PAA-PMA) to the tap water until the content of PAA-PMA is 6mg / L, and get treated water for later use;

[0031] The molecular weight of the PAA-PMA used is 5000, and the molar ratio of acrylic acid:maleic anhydride is 1.5:1.

[0032] The second step, synthesis: Put 240g of isopentenol polyoxyethylene ether (molecular weight 2400), 20g of maleic anhydride, 4g of 2-acrylamide-2-methylpropanesulfonic acid AMPS into the reaction kettle equipped with thermometer and electric stirring And 110g of treated water, heated up to 40°C and stirred until completely dissolved, adjusted the pH value to 4 with 32wt% NaOH aqueous solution, then added 1.8g of 31% hydrogen peroxide, kept the temperature at 40°C, and began to continuously drop 11g of acrylic acid pre...

Embodiment 2

[0034] A kind of synthetic method of polycarboxylic acid type high slump water reducer, its steps are as follows:

[0035] The first step, preparation of treated water: add water treatment agent acrylic acid-maleic anhydride copolymer (PAA-PMA) to the tap water until the content of PAA-PMA is 3mg / L, and get treated water for later use;

[0036] The molecular weight of the PAA-PMA used is 4000, and the molar ratio of acrylic acid:maleic anhydride is 1.4:1.

[0037] The second step, synthesis: Put 252g of isopentenol polyoxyethylene ether (molecular weight 2400), 20g of maleic anhydride, 6g of AMPS and 116g of treated water into a reaction kettle equipped with a thermometer and electric stirring, raise the temperature to 40°C and stir until Completely dissolve, use 32wt% NaOH aqueous solution to adjust the pH value to 4, then add 1.47g 31% hydrogen peroxide, keep the temperature at 40°C, and start to continuously add 10g of acrylic acid, 1.33g of ferrous ammonium sulfate, 0.64g ...

Embodiment 3

[0039] A kind of synthetic method of polycarboxylic acid type high slump water reducer, its steps are as follows:

[0040] The first step, preparation of treated water: add water treatment agent acrylic acid-maleic anhydride copolymer (PAA-PMA) to the tap water until the content of PAA-PMA is 8mg / L, and get treated water for later use;

[0041] The molecular weight of the PAA-PMA used is 2000, and the molar ratio of acrylic acid:maleic anhydride is 1.1:1.

[0042] The second step, synthesis: put 360g of methallyl alcohol polyoxyethylene ether (molecular weight 2400), 20g of maleic anhydride, 4g of sodium methacrylate and 165g of treated water into a reaction kettle equipped with a thermometer and electric stirring. Raise the temperature to 40°C and stir until it is completely dissolved, adjust the pH value to 4 with 32wt% NaOH aqueous solution, then add 1.9g of 31% hydrogen peroxide, keep the temperature at 40°C, and start to continuously drop the previously prepared 15g of ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com