Catalyst for methanation, and preparation method and application thereof

A catalyst, methanation technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Effect of good resistance, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example is used to illustrate the preparation of the catalyst of the present invention.

[0040] 140g Ni(NO 3 ) 2 , 16.4g La(NO 3 ) 3 Dissolve in water, add 31.5g Al 2 o 3 , made into powder by mixing and impregnating, crushed properly and rolled into pellets with a particle diameter of about 4 mm, as the core of the catalyst.

[0041] 6.2g Sr(NO 3 ) 2 , 1.1g NH 4 VO 3 After dissolving in water, saturate impregnate the inner core, dry at 90°C for 12 hours, and bake at 400°C for 6 hours to form an intermediate layer.

[0042] Al 2 o 3 The powder is rolled on the surface of the above-mentioned intermediate layer as a shell, that is, a catalyst with a particle size of about 5mm is made.

[0043] After measurement and conversion, in the catalyst, Ni element accounts for 44.58wt%, La element accounts for 6.95wt%, and Sr and V elements account for 3.02wt%.

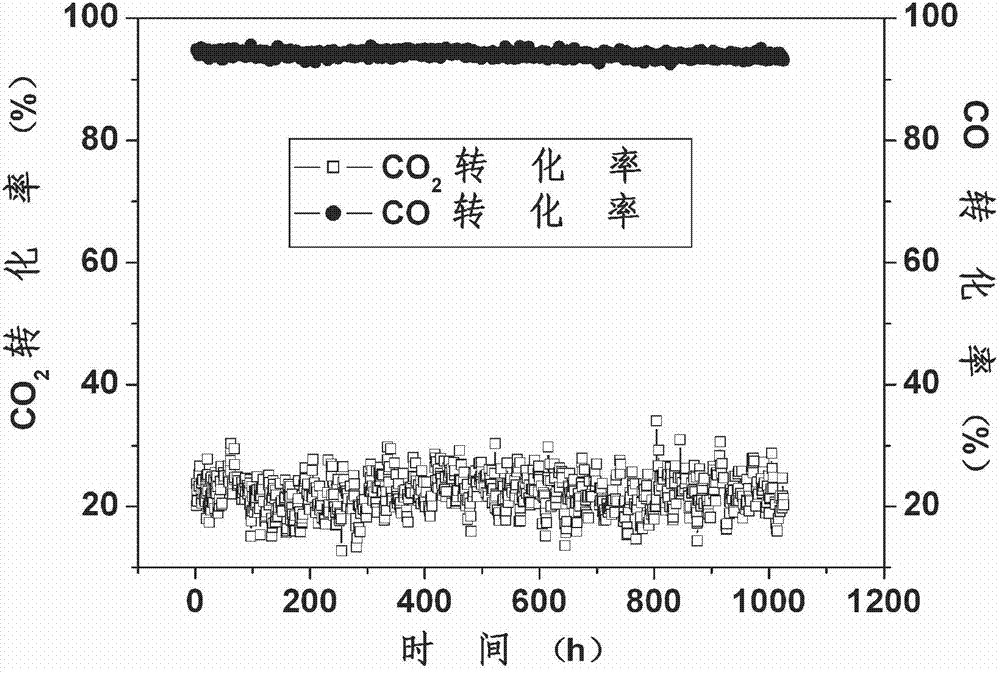

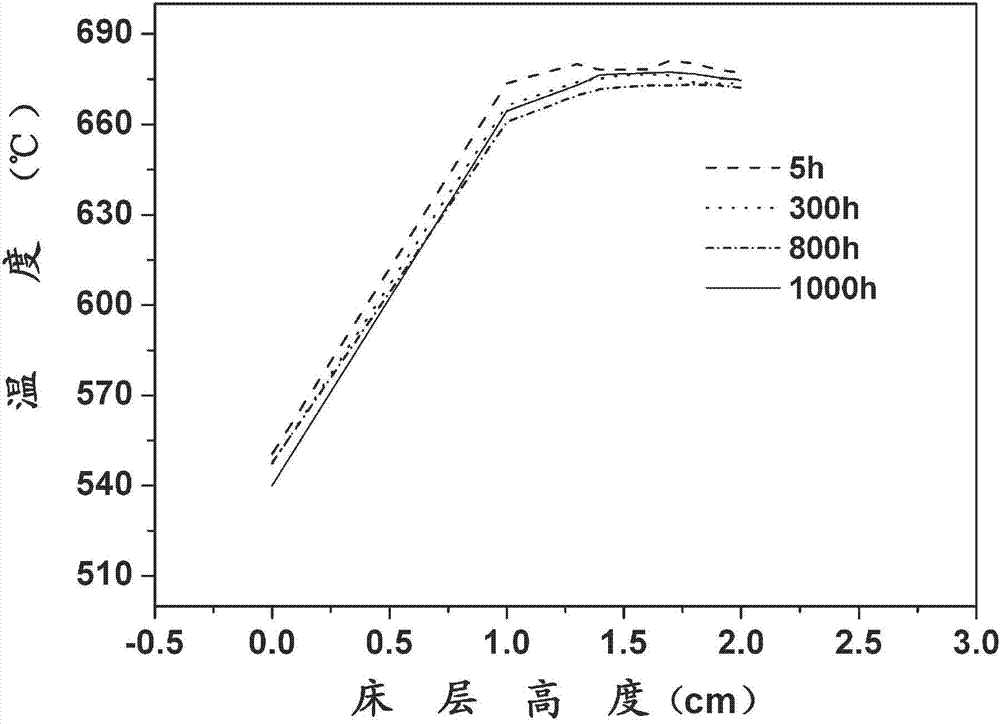

[0044] The catalyst was reduced for 4 hours at 600°C in a hydrogen atmosphere, and then the catalyst ...

Embodiment 2

[0052] This example is used to illustrate the preparation of the catalyst of the present invention.

[0053] 124.8g Ni(NO 3 ) 2 , 16.4g La(NO 3 ) 3 Dissolve in water, add 35.5g Al 2 o 3 , made into powder by mixing and impregnating, crushed properly and rolled into pellets with a particle diameter of about 4 mm, as the core of the catalyst.

[0054] 6.2g Sr(NO 3 ) 2 , 1.1g NH 4 VO 3 , 4.1g Ca(NO 3 ) 2 , 2.3g Cr(NO 3 ) 3 After dissolving in water, saturate impregnate the inner core, dry at 120°C for 8 hours, and bake at 600°C for 4 hours to form an intermediate layer.

[0055] Al 2 o 3 The powder is rolled on the surface of the above-mentioned intermediate layer as a shell, that is, a catalyst with a particle size of about 5mm is made.

[0056] After measurement and conversion, in the catalyst, Ni element accounts for 40.64wt%, La element accounts for 7.11wt%, and Sr, V, Ca and Cr elements account for 4.61wt%.

[0057] The catalyst was reduced for 4 hours at 60...

Embodiment 3

[0065] This example is used to illustrate the preparation of the catalyst of the present invention.

[0066] 124.8g Ni(NO 3 ) 2 , 14g Ce(NO 3 ) 3 Dissolve in water, add 36.1g Al 2 o 3 , made into powder by mixing and impregnating, crushed properly and rolled into pellets with a particle diameter of about 4 mm, as the core of the catalyst.

[0067] 6.2g Sr(NO 3 ) 2 , 1.1g NH 4 VO 3 , 4.1g Ca(NO 3 ) 2 , 2.3g Cr(NO 3 ) 3 After dissolving in water, saturate impregnate the inner core, dry at 120°C for 8 hours, and bake at 600°C for 4 hours to form an intermediate layer.

[0068] Al 2 o 3 The powder is rolled on the surface of the above-mentioned intermediate layer as a shell, that is, a catalyst with a particle size of about 5mm is made.

[0069] After measurement and conversion, in the catalyst, Ni element accounts for 40.87wt%, La element accounts for 6.13wt%, and Sr, V, Ca and Cr elements account for 4.64wt%.

[0070] The catalyst was reduced for 4 hours at 600°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com