Method for preparing boron-doped diamond and carbon nanotube composite nanocone

A carbon nanotube composite and multi-walled carbon nanotube technology, which is applied in the field of nanomaterials, can solve problems such as non-existence, and achieve the effects of size and density controllability, low field emission threshold voltage, and long emission life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

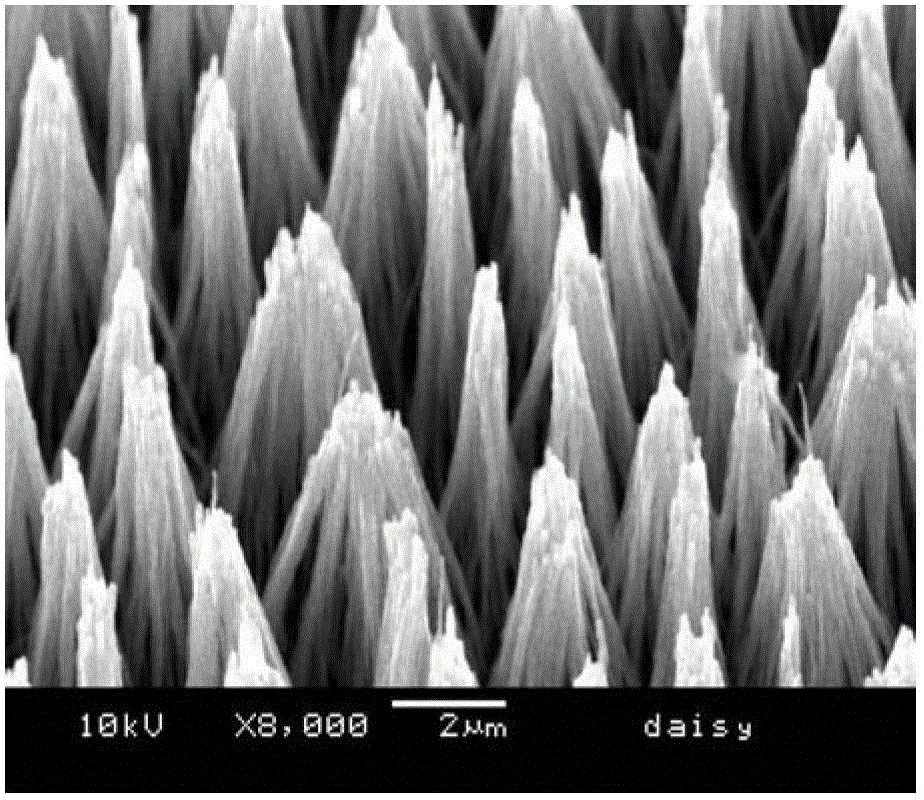

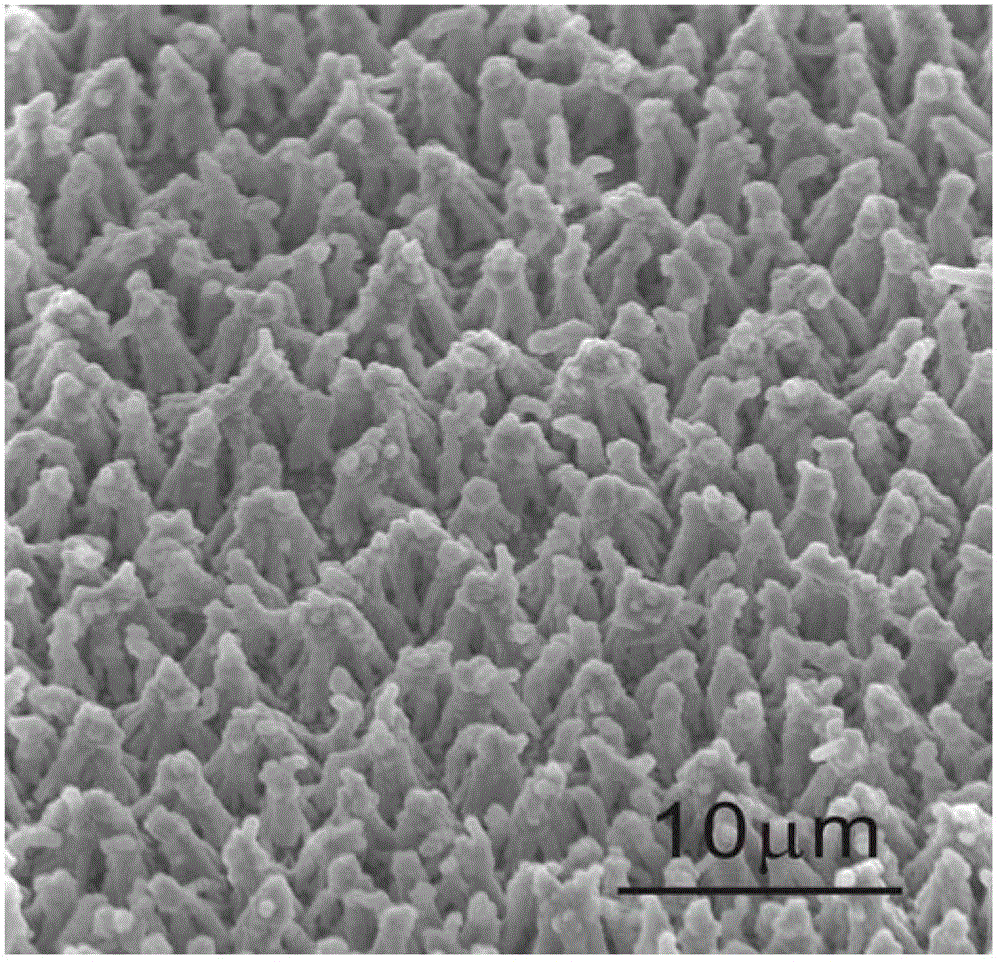

[0019] The invention provides a method for preparing boron-doped diamond and carbon nanotube composite nano-cones. Nano-diamond particles are pre-deposited on the surface of vertically oriented multi-walled carbon nanotubes by electrostatic spraying, and the carbon nano- The tubes are aggregated into a cone-shaped structure; further, a boron-doped diamond film is deposited on the carbon nanotube cone-shaped structure by hot filament chemical vapor deposition to form a composite nanocone of boron-doped diamond and carbon nanotubes with good field emission properties. , including the following steps:

[0020] Step 1, performing surface cleaning treatment on the monocrystalline silicon substrate. The specific operation is: first immerse the substrate in a mixed solution of acetone and ethanol for ultrasonic cleaning, then put it into deionized water for ultrasonic cleaning, and then dry it with cold air;

[0021] Step 2, sequentially sputter deposit a layer of SiO with a thickne...

Embodiment 1

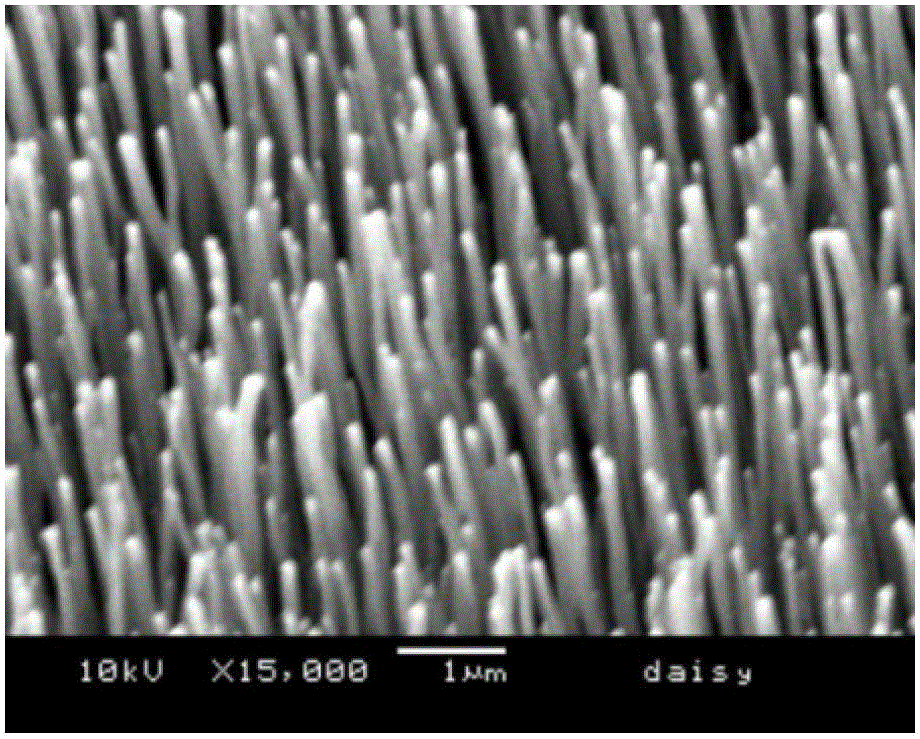

[0028] Multi-walled carbon nanotubes were prepared by plasma-enhanced chemical vapor deposition, and nano-diamond particles were pre-deposited on the surface of vertically oriented multi-walled carbon nanotubes by electrostatic spraying, and the carbon nanotubes were aggregated into cones under the action of electrostatic force Structure; further adopting hot wire chemical vapor deposition method to deposit a layer of boron-doped diamond film on the carbon nanotube cone structure to form a boron-doped diamond and carbon nanotube composite nanocone with good field emission performance, which specifically includes the following steps :

[0029] Step 1, performing surface cleaning treatment on the monocrystalline silicon substrate. The specific operation is: first immerse the substrate in a mixed solution of acetone and ethanol for ultrasonic cleaning, then put it into deionized water for ultrasonic cleaning, and then dry it with cold air;

[0030] Step 2, sequentially sputter d...

Embodiment 2

[0037] Multi-walled carbon nanotubes were prepared by plasma-enhanced chemical vapor deposition, and nano-diamond particles were pre-deposited on the surface of vertically oriented multi-walled carbon nanotubes by electrostatic spraying, and the carbon nanotubes were aggregated into cones under the action of electrostatic force Structure; further adopting hot wire chemical vapor deposition method to deposit a layer of boron-doped diamond film on the carbon nanotube cone structure to form a boron-doped diamond and carbon nanotube composite nanocone with good field emission performance, which specifically includes the following steps :

[0038] Step 1, performing surface cleaning treatment on the monocrystalline silicon substrate. The specific operation is: first immerse the substrate in a mixed solution of acetone and ethanol for ultrasonic cleaning, then put it into deionized water for ultrasonic cleaning, and then dry it with cold air;

[0039] Step 2, sequentially sputter d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com