Low-carbon and carbon-absorbing concrete and preparation method thereof

A technology for concrete and mixture, applied in the field of low-carbon and carbon-absorbing concrete and its preparation, can solve the problem of limited use of high-calcium fly ash, and achieve the effects of high strength and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

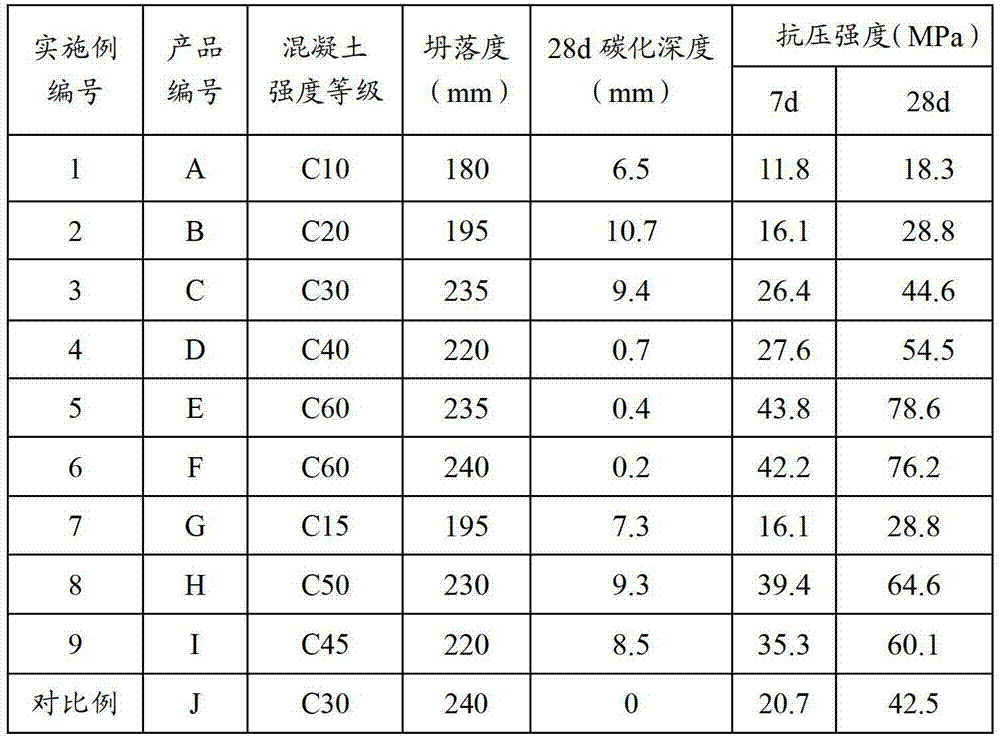

Examples

Embodiment 1

[0029] (1) Mix 29kg of Portland cement, 174kg of slag powder, 87kg of high-calcium fly ash with a calcium oxide content of 8wt%, and 6kg of industrial gypsum to obtain a mixed material;

[0030] (2) Mix the mixed material in the above step (1) with the aggregate of 1860kg to obtain the mixture, wherein the aggregate is stone and sand, and the sand ratio of the aggregate is 55%;

[0031] (3) Dissolve 1.5kg of naphthalene-based water reducer in 188.5kg of water to obtain an aqueous solution of water reducer;

[0032] (4) Add the water reducer aqueous solution in the step (3) to the mixture in the step (2), and stir evenly to obtain the low-carbon and carbon-absorbing concrete A.

Embodiment 2

[0034] (1) Mix 80kg of fly ash Portland cement, 160kg of slag powder with a vitreous content of 90.7wt%, 100kg of high-calcium fly ash with a calcium oxide content of 10.2wt%, and 8kg of natural gypsum to obtain Mixed material;

[0035] (2) Mix the mixed material in the above step (1) with the aggregate of 1824kg to obtain the mixture, wherein the aggregate is stone and sand, and the sand rate of the aggregate is 48%;

[0036] (3) Dissolve 2.7kg of aliphatic water reducer in 170kg of water to obtain an aqueous solution of water reducer;

[0037] (4) Add the water reducer aqueous solution in the step (3) to the mixture in the step (2), and stir evenly to obtain the low-carbon and carbon-absorbing concrete B.

Embodiment 3

[0039] (1) Mix 180kg of slag portland cement, 120kg of slag powder with a vitreous content of 97.5wt%, 90kg of high-calcium fly ash with a calcium oxide content of 12.4wt%, and 9kg of sodium sodium sulfate to obtain a mixed Material;

[0040] (2) Mix the mixed material in the above step (1) with the aggregate of 1786kg to obtain the mixture, wherein the aggregate is stone and sand, and the sand ratio of the aggregate is 45%;

[0041] (3) Dissolve 3.8kg of sulfamate water reducer in 167.7kg of water to obtain an aqueous solution of water reducer;

[0042] (4) Add the water reducer aqueous solution in the step (3) to the mixture in the step (2), and stir evenly to obtain the low-carbon and carbon-absorbing concrete C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com