Method for removing heavy and light impurities in maleic anhydride system

A heavy impurity, maleic anhydride technology, applied in the field of maleic anhydride production, can solve the problems of multi-circulating cooling water and electricity, clogging equipment and pipelines, unsatisfactory, etc., to reduce operation and maintenance costs, solve equipment clogging, reduce The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

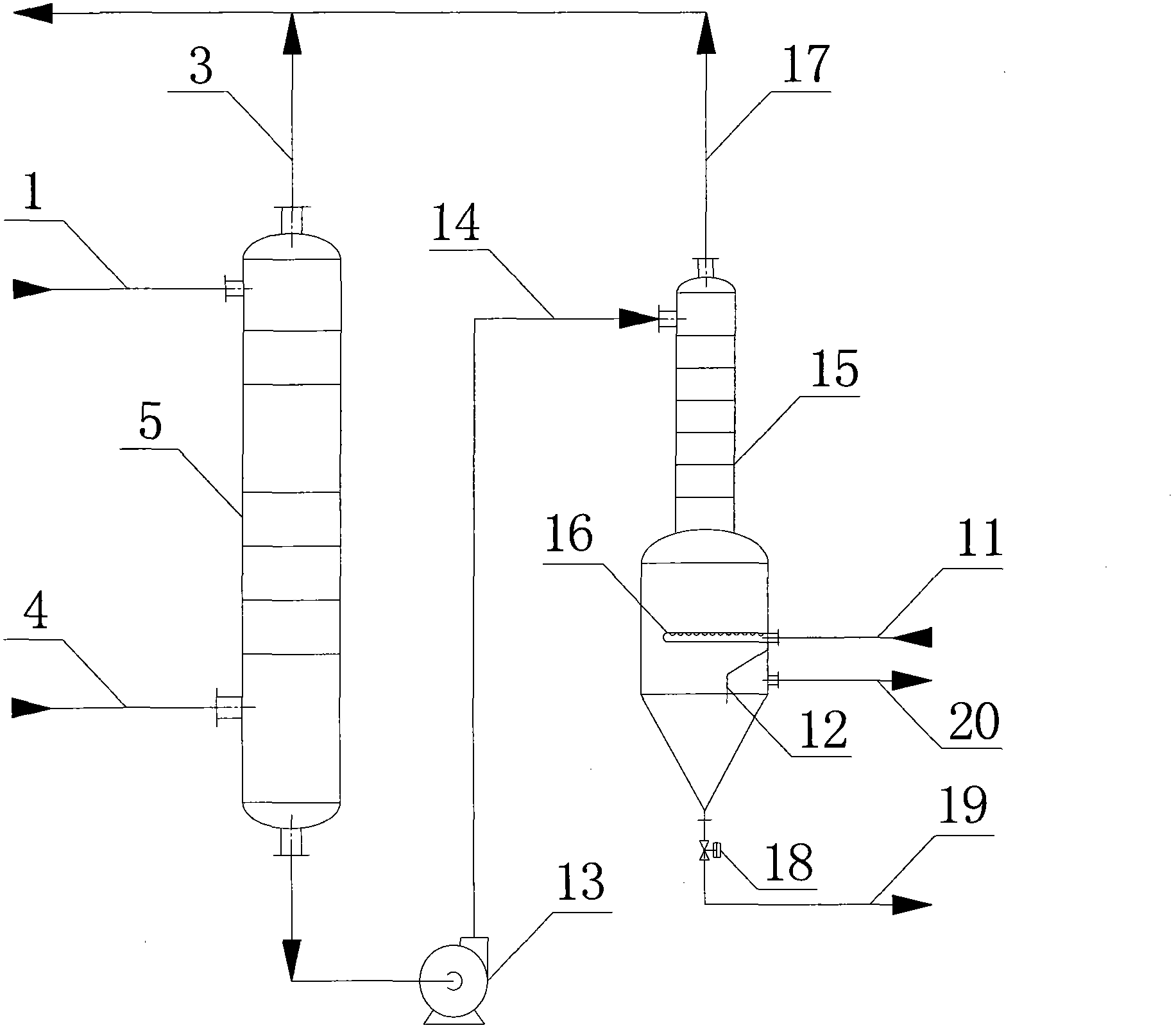

[0026] according to the invention image 3 The device is absorbed by the solvent 1 and becomes rich in maleic anhydride. The rich solvent 14 is passed into the upper part of the conical column kettle stripping tower 15, and the high-temperature compressed air 11 is passed into the stripping tower through the air distributor 16 on the tray. Contact with the rich solvent 14, the water, acetic acid, acrylic acid and other light impurities in the rich solvent are lifted to the top of the tower and taken out, and sent to the tail gas treatment 17; at this time, the valve 18 at the bottom of the tower is in a closed state, and the liquid in the tower kettle rich solvent The level will gradually rise, and when the liquid level exceeds the air distributor 16, the rich solvent will be extracted 20; heavy impurities have been accumulated in the tower kettle, and after a period of operation, the valve at the bottom of the tower is opened to cut out the heavy impurities and go to the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com